Information injection-pump assembly

ZEXEL

106873-7721

1068737721

Rating:

Service parts 106873-7721 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME161933

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/24.5{250}

14.

NOZZLE

Include in #1:

106873-7721

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106873-7721

1068737721

Zexel num

Bosch num

Firm num

Name

106873-7721

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.7

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

144

139.7

148.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

445

445

445

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.7)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

143

145

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

139

135

143

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.8)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

139.5

135.5

143.5

Fixing the lever

*

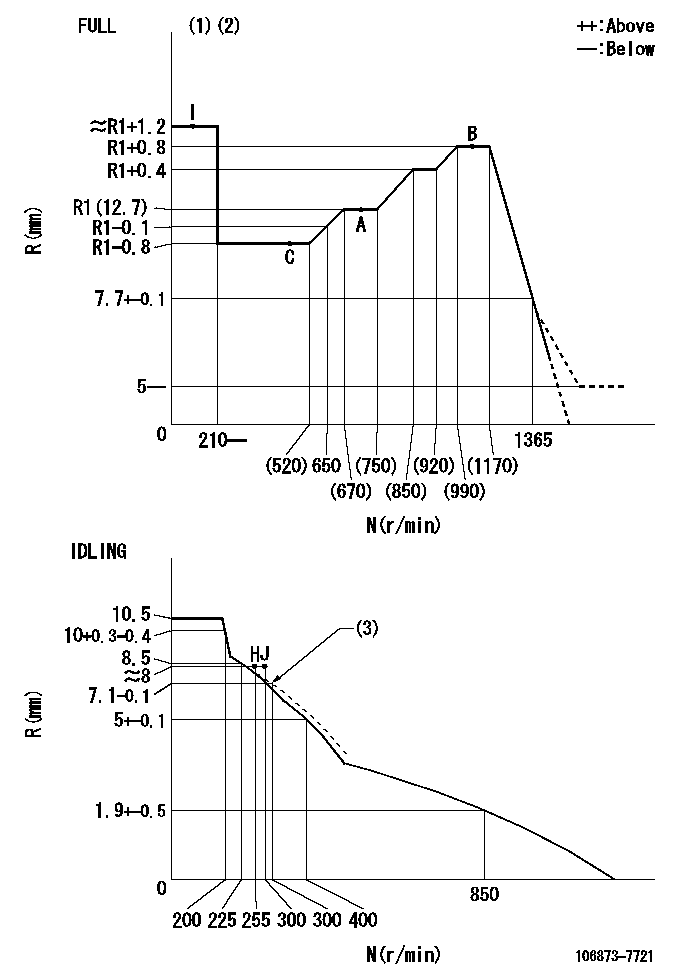

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AD95

----------

----------

T1=AD95

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

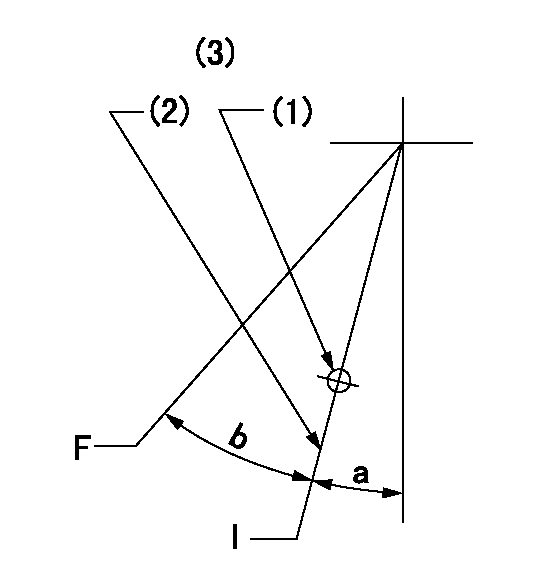

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

(3)Viewed from feed pump side.

----------

aa=37.5mm

----------

a=30deg+-5deg b=(37deg)+-3deg

----------

aa=37.5mm

----------

a=30deg+-5deg b=(37deg)+-3deg

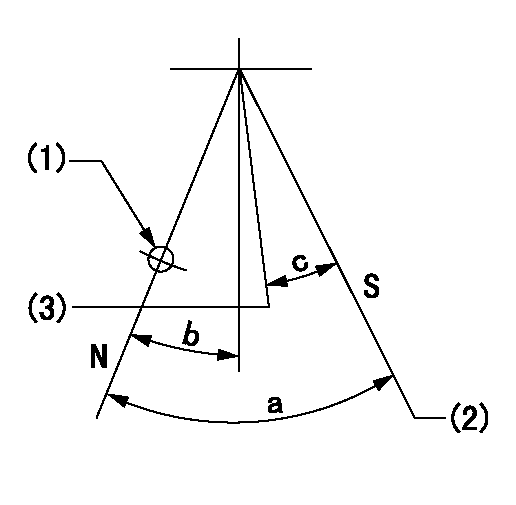

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

(3)Normal engine position (Rack position corresponding to dd)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(12.7)+0.8mm

----------

----------

N1=1100r/min Ra=R1(12.7)+0.8mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(50deg)

----------

aa=6deg

----------

a=(50deg)

Information:

Guidelines For Reusable Parts; Valves And Valve Springs, Forms SEBF8002 and SEBF8034 have the procedure and specifications necessary for checking used valves and valve springs.(1) Springs (Inner And Outer):Inner Valve Spring (4W2472): Assembled length ... 50.24 mm (1.978 in)Load at assembled length ... 178 18 N (40.1 4.1 lb)Operating length (min) ... 35.97 mm (1.416 in)Load at min operating length ... 343 17 N (77.2 3.8 lb)Free length after test ... 65.7 mm (2.60 in)Outside diameter ... 25.13 mm (.989 in)Outer Valve Spring (4W2471): Assembled length ... 53.24 mm (2.096 in)Load at assembled length ... 245 24 N (55.1 5.4 lb)Operating length (min) ... 38.96 mm (1.534 in) Load at min operating length ... 805 40 N (181.1 9.0 lb)Free length after test ... 59.5 mm (2.34 in)Outside diameter ... 37.31 mm (1.469 in) The following springs (inner and outer) are used on the exhaust valves with the 70 PSI Williams Blue-Ox Exhaust Brake.Inner Valve Spring (9Y3327): Assembled length ... 50.24 mm (1.978 in)Load at assembled length ... 264 26 N (59.4 5.9 lb)Operating length (min) ... 36.14 mm (1.423 in)Load at min operating length ... 445 22 N (100.1 5.0 lb)Free length after test ... 70.9 mm (2.79 in)Outside diameter ... 29.83 mm (1.174 in)Outer Valve Spring (9Y3326): Assembled length ... 53.24 mm (2.096 in)Load at assembled length ... 521 52 N (117.2 11.7 lb)Operating length (min) ... 38.96 mm (1.534 in)Load at min operating length ... 992 50 N (223.2 11.3 lb)Free length after test ... 69.04 mm (2.718 in)Outside diameter ... 42.61 mm (1.678 in)(2) Height to top of valve guide ... 32.3 0.8 mm (1.27 .03 in)(3) Diameter of valve stem (new) ... 9.441 0.008 mm (.3717 .0003 in) Coat the intake and exhaust valve stems with 8T2998 Camshaft Lubricant prior to installation in the cylinder head.Use again minimum:1W3860 Exhaust ... 9.408 mm (.3704 in)2W2622 Intake ... 9.408 mm (.3704 in)Bore in valve guide with guide installed in the head (new) ... 9.487

Have questions with 106873-7721?

Group cross 106873-7721 ZEXEL

Mitsubishi

Mitsubishi

106873-7721

INJECTION-PUMP ASSEMBLY