Information injection-pump assembly

ZEXEL

106873-7630

1068737630

Rating:

Service parts 106873-7630 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME161933

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/24.5{250}

14.

NOZZLE

Include in #1:

106873-7630

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106873-7630

1068737630

Zexel num

Bosch num

Firm num

Name

106873-7630

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.6

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

142

137.7

146.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

445

445

445

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.6)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

142

141

143

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.85

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

138

134

142

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.8)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

138

134

142

Fixing the lever

*

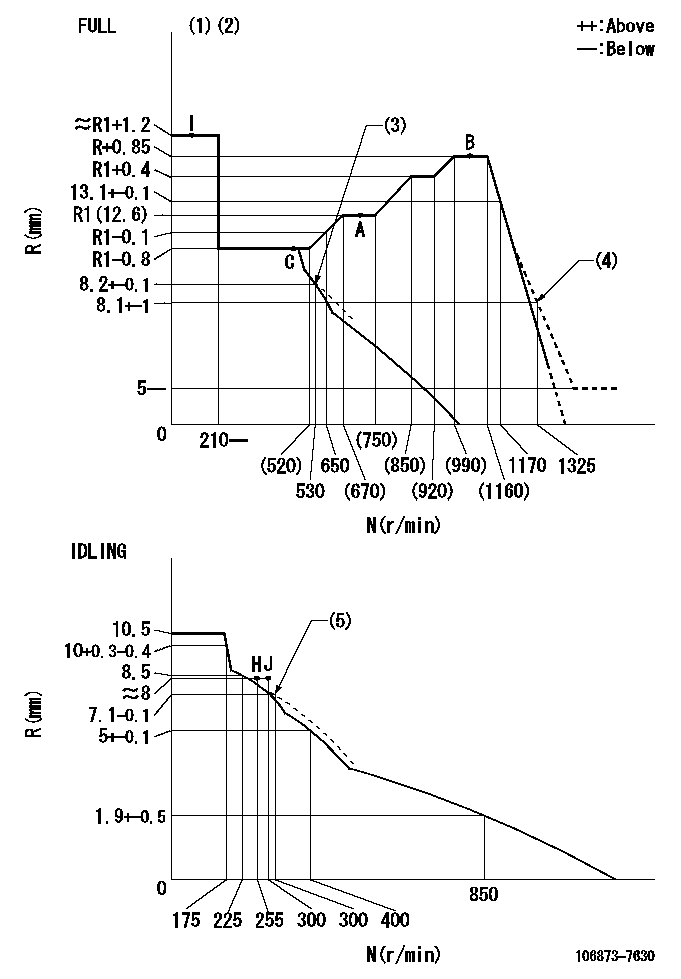

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Air cylinder ON

(4)Air cylinder OFF

(5)Damper spring setting

----------

T1=AD95

----------

----------

T1=AD95

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

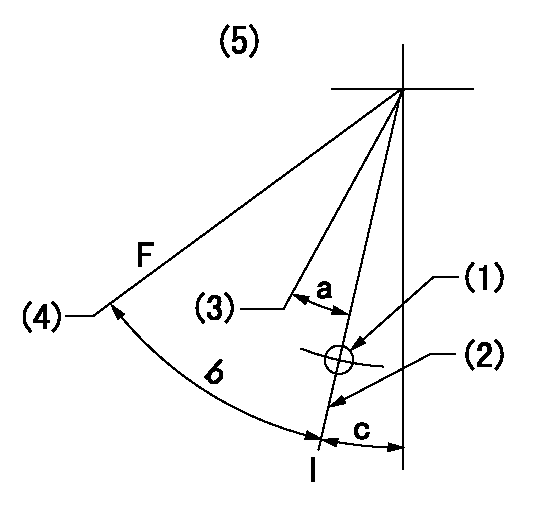

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

(3)When air cylinder ON.

(4)When air cylinder OFF.

(5)Viewed from feed pump side.

----------

aa=37.5mm

----------

a=(16deg) b=35deg+-3deg c=30deg+-5deg

----------

aa=37.5mm

----------

a=(16deg) b=35deg+-3deg c=30deg+-5deg

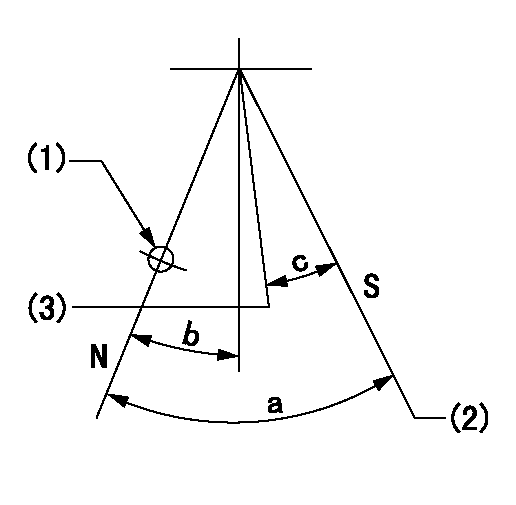

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

(3)Normal engine position (Rack position corresponding to dd)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(12.6)+0.85mm

----------

----------

N1=1100r/min Ra=R1(12.6)+0.85mm

----------

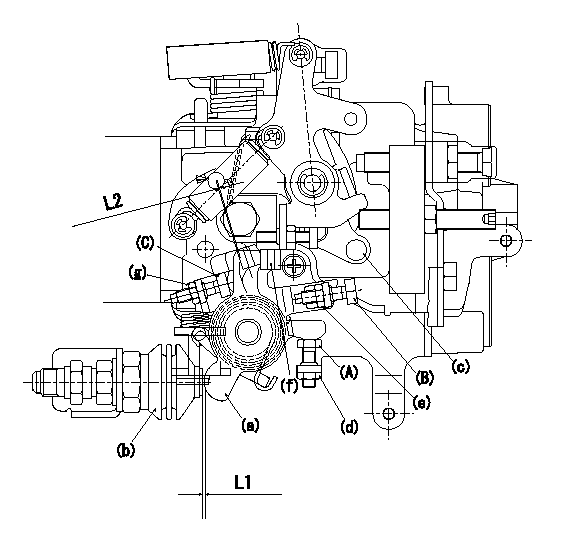

0000001601 AIR CYLINDER

<A> stopper bolt

<B> stopper bolt

<C> stopper bolt

(a) lever

(b) air cylinder

(c) speed lever

(d) Nut

(e) nut

(f) lever

(g) nut

1. Stopper bolt <A> adjustment method

(1)When air cylinder pressure is P1, set the gap between the lever (a) and the air cylinder (b) to L1.

(2)Confirm that the speed lever (c) operates between idling and full speed.

(3)Fix stopper bolt <A> using nut (d).

2. Stopper bolt <B> adjustment method.

(1)At air cylinder pressure P2, pump speed N1 and rack position is R1, adjust stopper bolt (B) so that the speed lever (c) is in the stop position.

(2)Turn the stopper bolt (c) so that the clearance between lever (a) and lever (f) is L2, then fix using nut (g).

(3)Move the lever (a) several times and fix stopper bolt <B> using the nut (e).

(4)Tightening torque T1 for nuts (d), (e) and (g)

----------

L1=1+0.5++mm L2=0~1.5++mm P1=0kPa(0kgf/cm2) P2=686+98kpa(7+1kgf/cm2) N1=530r/min R1=8.2+-0.1mm T1=4.9~6.86N-m(0.5~0.7kgf-m)

----------

----------

L1=1+0.5++mm L2=0~1.5++mm P1=0kPa(0kgf/cm2) P2=686+98kpa(7+1kgf/cm2) N1=530r/min R1=8.2+-0.1mm T1=4.9~6.86N-m(0.5~0.7kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=6deg

----------

a=(50deg)

----------

aa=6deg

----------

a=(50deg)

Information:

1. Remove the pickup from the injection line. Check to be sure the pickup and injection line are clean and dry. The inner bore of the pickup that contacts the injection line must be clean and dry. If necessary, clean the inner bore with a soft dry cloth. If the pickup is damp, dry it in an oven at approximately 50°C (122°F) before reinstalling on the fuel injection line.2. Check the fuel injection line on which the pickup was installed. Make sure all paint has been removed from around the line and that clean bare metal is exposed. Use fine emery paper to clean the line if necessary.3. Reinstall the pickup on the fuel injection line. Make sure the thumbscrew is tight and the pickup is not touching anything except the line. Observe the NO INPUT SIGNAL light and the digital readout on the multitach. If the light stays on bright all the time and the digital display reads 0 when the engine is running, the pickup is not operating. Remove the pickup and amplifier, and test the pickup and amplifier as shown on pages 6 and 7, or use a different pickup and amplifier.4. If the pickup is operating but the NO INPUT SIGNAL light and digital readout are erratic, the pickup output signal is either too low or it is noisy. Run the engine at low and high speeds. If the output signal is too low, the pickup will operate better at high engine speeds. If the signal is noisy, the pickup will usually perform better at low engine speeds. To correct either of these problems, loosen the thumbscrew and rotate the pickup to a new position on the line. Tighten the thumbscrew. Check to see if this solves the problem. To correct noisy operation, it may also be necessary to remove the pickup and reverse it 180° so the signal line points in the opposite direction.5. If pickup operation is still erratic after performing the previous steps, move the pickup to a new location on the same line or to a different line. Make sure each new location is properly prepared before installing pickup. To correct noisy operation (erratic signal and high speed readings), try a pickup location as close as possible to a point where the injection line is fastened to the engine.(D) Use Of The Pickup During Wet Conditions

If the pickup becomes wet, it may operate intermittently or not at all. Although the pickup is water resistant, it is not waterproof. Water spray from rain or other sources may cause the pickup to stop producing an output signal. If this happens, the pickup should be removed from the engine and allowed to dry out thoroughly. If necessary, the pickup can be dried in an oven at approximately 50°C (122°F). After drying, the pickup should operate correctly. If it is not possible to keep the pickup dry, use the following procedure. If the pickup must be used during wet conditions, it may be possible

If the pickup becomes wet, it may operate intermittently or not at all. Although the pickup is water resistant, it is not waterproof. Water spray from rain or other sources may cause the pickup to stop producing an output signal. If this happens, the pickup should be removed from the engine and allowed to dry out thoroughly. If necessary, the pickup can be dried in an oven at approximately 50°C (122°F). After drying, the pickup should operate correctly. If it is not possible to keep the pickup dry, use the following procedure. If the pickup must be used during wet conditions, it may be possible

Have questions with 106873-7630?

Group cross 106873-7630 ZEXEL

Mitsubishi

Mitsubishi

106873-7630

INJECTION-PUMP ASSEMBLY