Information injection-pump assembly

BOSCH

9 400 619 467

9400619467

ZEXEL

106873-7560

1068737560

Rating:

Service parts 106873-7560 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME093733

12.

Open Pre:MPa(Kqf/cm2)

15.

NOZZLE SET

Include in #1:

106873-7560

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 467

9400619467

ZEXEL

106873-7560

1068737560

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

115

111.5

118.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

430

430

430

Each cylinder's injection qty

mm3/st.

19

16.1

21.9

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

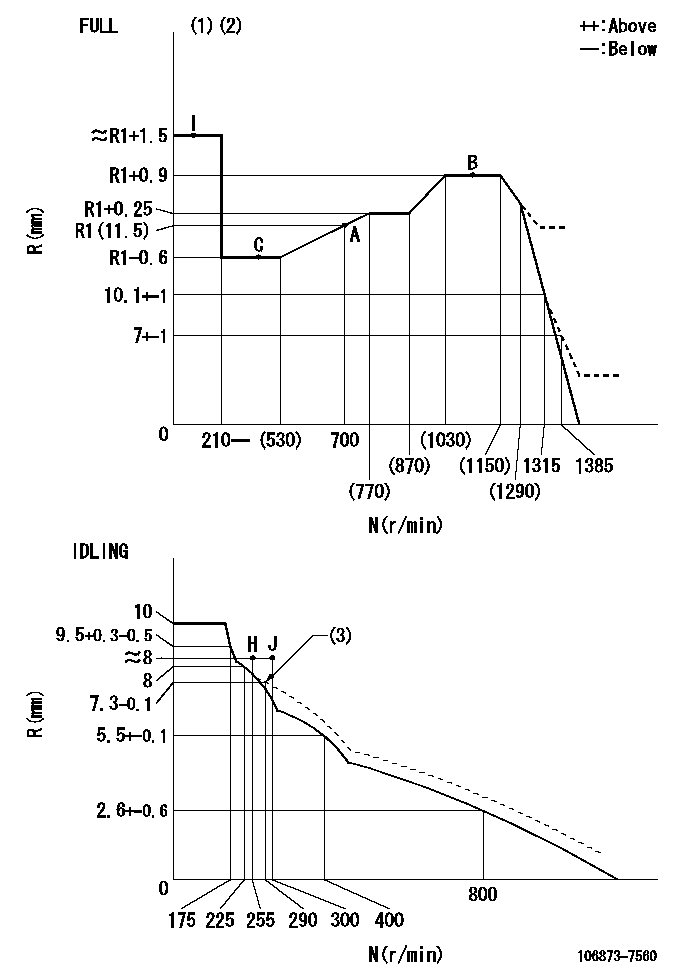

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

115

114

116

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

117

113

121

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

111

107

115

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AC74

----------

----------

T1=AC74

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

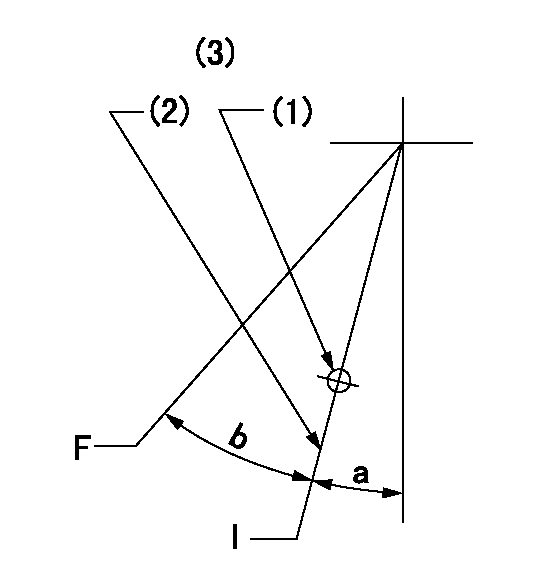

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

(3)Viewed from feed pump side.

----------

aa=37.5mm

----------

a=32deg+-5deg b=(42deg)+-3deg

----------

aa=37.5mm

----------

a=32deg+-5deg b=(42deg)+-3deg

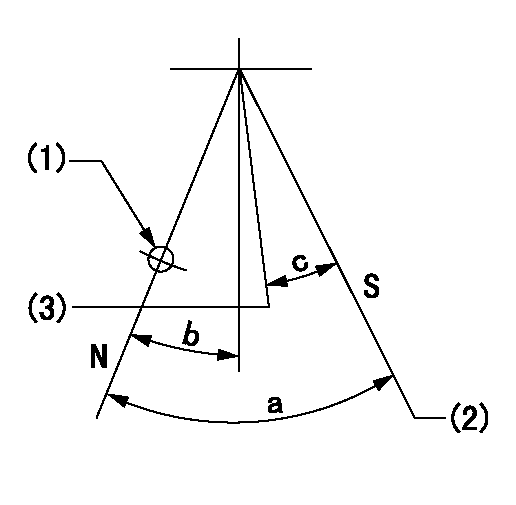

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

(3)Normal engine position (Rack position corresponding to dd)

----------

aa=54mm bb=1100r/min cc=3+-0.3mm dd=17.5mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

----------

aa=54mm bb=1100r/min cc=3+-0.3mm dd=17.5mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(11.5)+0.9mm

----------

----------

N1=1100r/min Ra=R1(11.5)+0.9mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=4deg

----------

a=(50deg)

----------

aa=4deg

----------

a=(50deg)

Information:

When using an external electrical source to start your engine: turn the START switch off, remove the key, and turn off all electrical accessories before attaching cables.When using jumper cables always connect the POSITIVE (+) cable to the POSITIVE (+) terminal of the battery connected to the starter solenoid. Connect the NEGATIVE (-) cable from the external source to the starter NEGATIVE (-) terminal. If not equipped with a starter NEGATIVE terminal, connect to the engine block.Do not reverse the battery cables. The alternator can be damaged. Attach the ground cable last and remove first.

1. Connect one end of the cable to the POSITIVE (+) terminal of the battery being started. Connect the other end to the POSITIVE (+) terminal of the power source.2. Connect one of the other cable to the NEGATIVE (-) terminal of the power source. Connect the other end to starter NEGATIVE (-) terminal or to the engine block. This prevents potential sparks from igniting combustible gases produced by some batteries.3. Start the engine.4. After the engine starts, disconnect the cable from the starter NEGATIVE (-) terminal or engine block. Disconnect the other end from the NEGATIVE (-) terminal of the power source.5. Disconnect the cable from the POSITIVE (+) terminal of the battery on the engine being started. Disconnect the cable from the POSITIVE (+) terminal of the power source.Air Starting

For good life of the air starting motor, the air supply must be free of dirt and water. A lubricator must be used with the starting system. Use non detergent 10W engine oil for temperatures that are greater than 0°C (32°F) or use air tool oil for lower temperatures.1. Open and close the drain valve on the bottom of the air tank to drain condensation and oil carryover.2. Check the air supply pressure. The air starting motor requires a minimum of 690 kPa (100 psi) air pressure to operate properly. The maximum air pressure must not exceed 1550 kPa (225 psi). The normal air pressure will be 758 to 965 kPa (110 to 140 psi).

Air Starter showing Air Valve (1) and Lubricator Bowl (2)3. Check the oil level in the lubricator bowl (2). Keep the bowl at least half full and add lubricant if necessary.4. Push the air valve (1) or the engine start button to crank the engine. Release the valve or button as soon as the engine starts.Cold Weather Starting Aids

Personal injury or death can result from using ether.Personal injury or property damage can result from alcohol or starting fluids. Alcohol or starting fluids are highly flammable and toxic and if improperly stored could result in injury or property damage.When using starting fluid, follow the manufacturer's instructions carefully. Use ether sparingly and spray it only while cranking the engine.Failure to follow these instructions could result in an explosion and/or fire and possible personal injury.

Excessive ether can cause piston and ring damage. Use ether for cold starting purposes only. Do not use excessive starting fluid during starting or after the engine is