Information injection-pump assembly

BOSCH

9 400 618 494

9400618494

ZEXEL

106873-7490

1068737490

MITSUBISHI

ME098743

me098743

Rating:

Service parts 106873-7490 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME098744

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106873-7490

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 494

9400618494

ZEXEL

106873-7490

1068737490

MITSUBISHI

ME098743

me098743

Zexel num

Bosch num

Firm num

Name

106873-7490

9 400 618 494

ME098743 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9T K 14CD INJECTION PUMP ASSY PE8P PE

8DC9T K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

195.5

192.5

198.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

15

12.4

17.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

9.7

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

183

179

187

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

0.8

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3

2.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

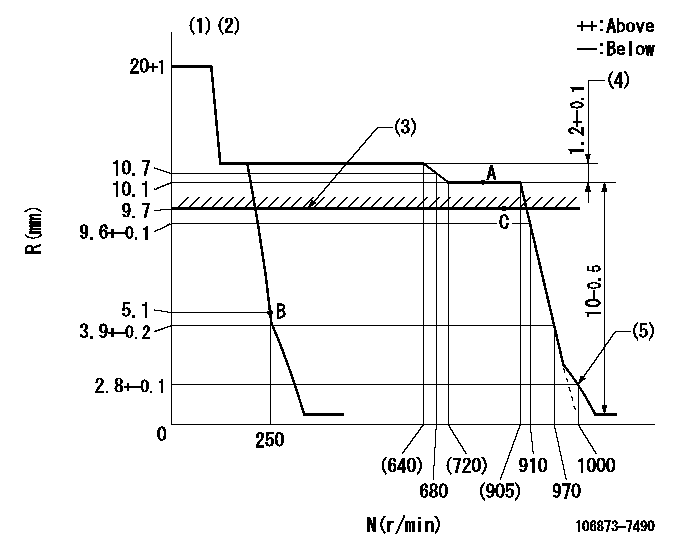

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

(5)Set idle sub-spring

----------

K=14 N1=850r/min N2=500r/min

----------

----------

K=14 N1=850r/min N2=500r/min

----------

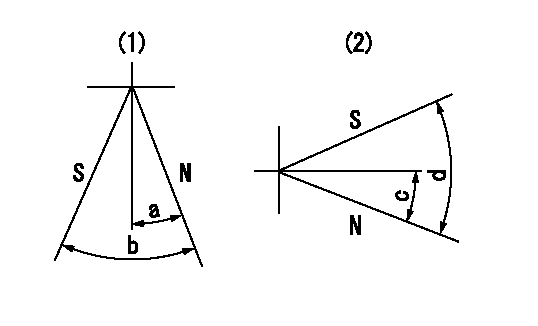

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=25deg+-5deg

----------

----------

a=9deg+-5deg b=25deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Right front

(2)Right rear

----------

----------

a=19deg+-5deg b=46deg+-5deg c=28deg+-5deg d=53deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg c=28deg+-5deg d=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Caterpillar Reference Material

The following literature can be obtained through any Caterpillar dealer.Oil

SEBD0640, Oil and Your EnginePEDP7122, Question & Answer BookletPEDP1129, Listen To Your OilPEHP6001, How to Take a Good Oil SampleSEBU6251, Lubricant RecommendationsPEHP1027, Product Data Sheet for Cat Diesel Engine Oil (CD)PEHP0002, Product Data Sheet for Cat Molybdenum Grease (MPGM)PEHP0003, Product Data Sheet for Cat Lithium Grease (MPGL)PEHP0017, Product Data Sheet for Cat Special Purpose Grease (SPG)PEWP9733, Cat Fluids SelectorPEDP7105, Scheduled Oil SamplingFuel

SEBD0717, Diesel Fuels and Your EngineCoolant

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EngineMiscellaneous

SEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSEHS9031, Storage Procedure for Caterpillar ProductsSENR5226, Service Manual (EMCP)SEBU6150, SR4 Generators and Control Panels Operation and Maintenance ManualSEBU6918, SR4B Generators and Control Panels Operation and Maintenance ManualSENR7337, Service Manual, 3408 and 3408B Industrial and Marine EnginesSENR7405, Service Manual, 3412 Industrial and Marine EnginesSENR2559, Service Manual, 3408 and 3412 Generator Set EnginesSEHS7654, Alignment-General InstructionsSEHS9124, Cleaning and Drying of Caterpillar Electric Set GeneratorsLEBH9324, Agricultural and Material Handling Application and Installation GuideSEHS7292, Use of 5P4150 Nozzle Testing GroupSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS7795, Use of Pump & Governor Tool GroupSEHS8024, Governor Adjusting Tool GroupSEHS8094, Use of Nozzle Puller GroupAdditional Reference Material

ASTM D2896- TBN MeasurementsASTM D21768- Worked PenetrationASTM D2982B- Ethylene Glycol ContentASTM D3828A- Fuel DilutionASTM D445- ViscosityASTM D893- InsolublesASTM 498589- GM-6038M SpecificationASTM Specs can normally be obtained from your local technological society, library or college.SAE J313- Diesel FuelsSAE J754- NomenclatureSAE J183- ClassificationSociety of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college, or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers AssociationLubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

The following literature can be obtained through any Caterpillar dealer.Oil

SEBD0640, Oil and Your EnginePEDP7122, Question & Answer BookletPEDP1129, Listen To Your OilPEHP6001, How to Take a Good Oil SampleSEBU6251, Lubricant RecommendationsPEHP1027, Product Data Sheet for Cat Diesel Engine Oil (CD)PEHP0002, Product Data Sheet for Cat Molybdenum Grease (MPGM)PEHP0003, Product Data Sheet for Cat Lithium Grease (MPGL)PEHP0017, Product Data Sheet for Cat Special Purpose Grease (SPG)PEWP9733, Cat Fluids SelectorPEDP7105, Scheduled Oil SamplingFuel

SEBD0717, Diesel Fuels and Your EngineCoolant

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EngineMiscellaneous

SEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts - Cleaning and Inspection of Air FiltersSEHS9031, Storage Procedure for Caterpillar ProductsSENR5226, Service Manual (EMCP)SEBU6150, SR4 Generators and Control Panels Operation and Maintenance ManualSEBU6918, SR4B Generators and Control Panels Operation and Maintenance ManualSENR7337, Service Manual, 3408 and 3408B Industrial and Marine EnginesSENR7405, Service Manual, 3412 Industrial and Marine EnginesSENR2559, Service Manual, 3408 and 3412 Generator Set EnginesSEHS7654, Alignment-General InstructionsSEHS9124, Cleaning and Drying of Caterpillar Electric Set GeneratorsLEBH9324, Agricultural and Material Handling Application and Installation GuideSEHS7292, Use of 5P4150 Nozzle Testing GroupSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS7795, Use of Pump & Governor Tool GroupSEHS8024, Governor Adjusting Tool GroupSEHS8094, Use of Nozzle Puller GroupAdditional Reference Material

ASTM D2896- TBN MeasurementsASTM D21768- Worked PenetrationASTM D2982B- Ethylene Glycol ContentASTM D3828A- Fuel DilutionASTM D445- ViscosityASTM D893- InsolublesASTM 498589- GM-6038M SpecificationASTM Specs can normally be obtained from your local technological society, library or college.SAE J313- Diesel FuelsSAE J754- NomenclatureSAE J183- ClassificationSociety of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college, or technological society.* SAE handbooks can be obtained directly from:SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers AssociationLubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

Have questions with 106873-7490?

Group cross 106873-7490 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

106873-7490

9 400 618 494

ME098743

INJECTION-PUMP ASSEMBLY

8DC9T

8DC9T