Information injection-pump assembly

BOSCH

9 400 618 480

9400618480

ZEXEL

106873-7260

1068737260

MITSUBISHI

ME094010

me094010

Rating:

Cross reference number

BOSCH

9 400 618 480

9400618480

ZEXEL

106873-7260

1068737260

MITSUBISHI

ME094010

me094010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Rack position

(10.7)

Vist

V

1.86

1.86

1.86

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

125

124

126

Max. variation between cylinders

%

0

-3

3

Basic

*

Injection quantity adjustment_02

Rack position

(6.5)

Vist

V

2.7

2.6

2.8

Pump speed

r/min

380

380

380

Average injection quantity

mm3/st.

16

14

18

Max. variation between cylinders

%

0

-15

15

Test data Ex:

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

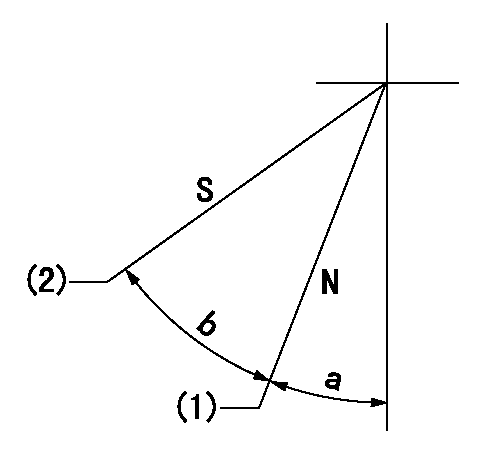

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=26deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=26deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=4deg

----------

a=(50deg)

----------

aa=4deg

----------

a=(50deg)

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

0000001201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (154610-0620)

(1)At governor side rack sensor output voltage V1, adjust the bobbin (A) so that the drive side rack sensor output voltage is VR+-0.01.

(2)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

V1=1V

----------

----------

V1=1V

----------

Information:

Proper operation and maintenance are key factors in obtaining the maximum life and economy of the engine. Following the directions in this Manual will lower operating costs.The time needed for the engine to reach the normal mode of operation is usually less than the time taken for a walk-around inspection of the engine. After the engine is started and the cold low speed operation is completed, the engine can be operated at rated speed and low power. The engine will reach normal operating temperature faster when operated at low power demand than when idled at no load. Typically the engine should reach operating temperature in a few minutes.Normal Mode

The electronic governor/control (ECM) system provides complete engine speed governing and controls cold start mode strategies, torque shaping, smoke limiting, system diagnostics and communication data links to monitor performance and diagnostic information. Warning outputs are provided for low oil pressure, low boost pressure, high coolant temperature and low coolant level with a diagnostic lamp.The purpose of normal mode is to monitor and control the genset. The GSC controls the engine according to the information received from the operator (panel switches, controls) and from the engine sensors. Some of the functions performed by the GSC while in normal mode are: engine starting, monitoring of important genset conditions, showing the operator the important genset conditions, fault detection, and engine stopping.The operator can identify normal mode by observing the display area. When in normal mode: all shutdown indicators are OFF, the fault alarm indicator is OFF and SERV is NOT displayed on the upper window. When the GSC is in normal mode, the engine is able to start or run. Refer to Engine Control, Monitoring and Protection topic for information regarding GSC control panel. In the AUTOmatic position (3 o'clock), the engine will start automatically whenever a remote initiating contact is closed. The engine will shutdown after the initiating contact opens and adjustable cooldown time elapsed. The cooldown time can be programmed to give a 0 to 30 minute cooldown period before the engine shuts down.In the MAN. START position (6 o'clock), the engine will start and run as long as the ECS switch remains in this position. In the COOLDOWN STOP position (9 o'clock), the fuel solenoid shuts the engine down, after a programmable cool down time period. In the OFF/RESET position (12 o'clock), the fault lights are reset and the engine shuts down immediately.1. Do not apply a load to the engine, or increase the speed until the oil pressure indicates normal. 2. Move the Manual Speed Potentiometer (MSP) to the (high idle-full load) position. 3. Apply the load to the driven equipment.4. Manually turn the MSP adjusting knob to change engine speed. To adjust or change engine speed droop setting, use the speed droop set screw. Control Panel Equipped Engines-Starting, Operating and Stopping

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to SR4 Generators and Control Panels Operation & Maintenance

The electronic governor/control (ECM) system provides complete engine speed governing and controls cold start mode strategies, torque shaping, smoke limiting, system diagnostics and communication data links to monitor performance and diagnostic information. Warning outputs are provided for low oil pressure, low boost pressure, high coolant temperature and low coolant level with a diagnostic lamp.The purpose of normal mode is to monitor and control the genset. The GSC controls the engine according to the information received from the operator (panel switches, controls) and from the engine sensors. Some of the functions performed by the GSC while in normal mode are: engine starting, monitoring of important genset conditions, showing the operator the important genset conditions, fault detection, and engine stopping.The operator can identify normal mode by observing the display area. When in normal mode: all shutdown indicators are OFF, the fault alarm indicator is OFF and SERV is NOT displayed on the upper window. When the GSC is in normal mode, the engine is able to start or run. Refer to Engine Control, Monitoring and Protection topic for information regarding GSC control panel. In the AUTOmatic position (3 o'clock), the engine will start automatically whenever a remote initiating contact is closed. The engine will shutdown after the initiating contact opens and adjustable cooldown time elapsed. The cooldown time can be programmed to give a 0 to 30 minute cooldown period before the engine shuts down.In the MAN. START position (6 o'clock), the engine will start and run as long as the ECS switch remains in this position. In the COOLDOWN STOP position (9 o'clock), the fuel solenoid shuts the engine down, after a programmable cool down time period. In the OFF/RESET position (12 o'clock), the fault lights are reset and the engine shuts down immediately.1. Do not apply a load to the engine, or increase the speed until the oil pressure indicates normal. 2. Move the Manual Speed Potentiometer (MSP) to the (high idle-full load) position. 3. Apply the load to the driven equipment.4. Manually turn the MSP adjusting knob to change engine speed. To adjust or change engine speed droop setting, use the speed droop set screw. Control Panel Equipped Engines-Starting, Operating and Stopping

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to SR4 Generators and Control Panels Operation & Maintenance