Information injection-pump assembly

ZEXEL

106873-7050

1068737050

Rating:

Cross reference number

ZEXEL

106873-7050

1068737050

Zexel num

Bosch num

Firm num

Name

106873-7050

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

12.2

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

109

105.7

112.3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.5+-0.5

Pump speed

r/min

510

510

510

Each cylinder's injection qty

mm3/st.

16

13.6

18.4

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.2)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

109

108

110

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.15

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

118

114

122

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.8)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

104

100

108

Fixing the lever

*

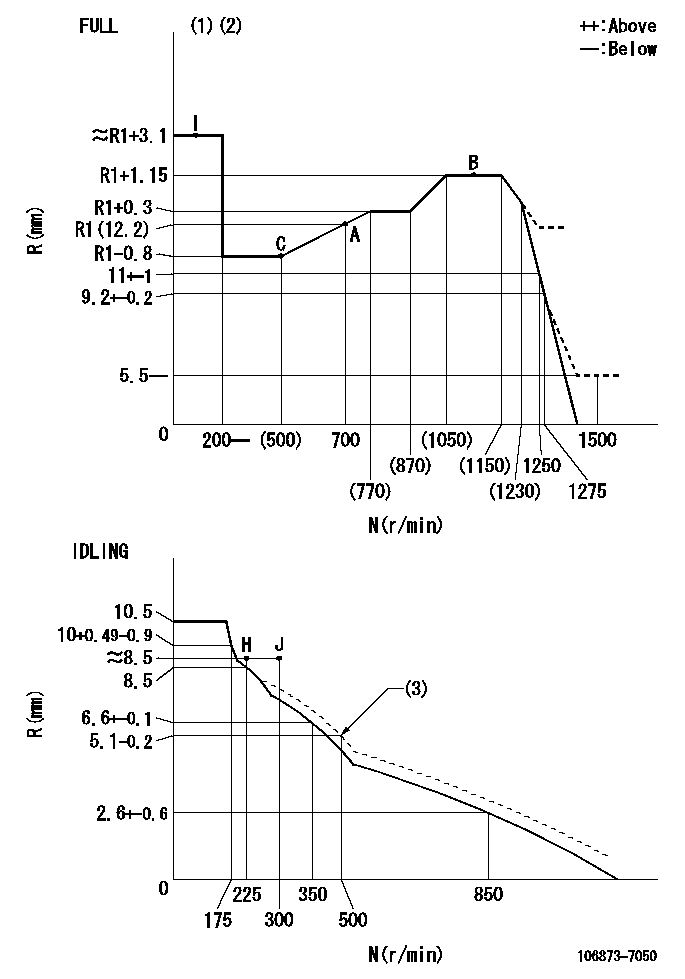

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AB22

----------

----------

T1=AB22

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(10)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=10+-0.3deg R01=0/4load R02=4/4load

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=30mm

----------

a=37deg+-5deg b=(44deg)+-3deg

----------

aa=30mm

----------

a=37deg+-5deg b=(44deg)+-3deg

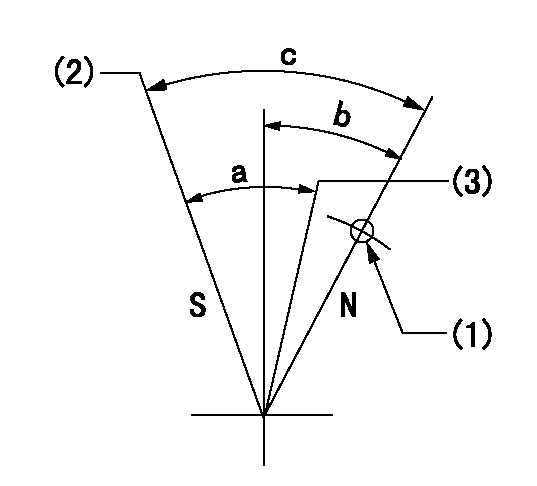

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

(3)Normal engine position (Rack position corresponding to dd)

----------

aa=45mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=(31deg)+-5deg b=25.5deg+-5deg c=41deg+-5deg

----------

aa=45mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=(31deg)+-5deg b=25.5deg+-5deg c=41deg+-5deg

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(12.2)+1.15mm

----------

----------

N1=1100r/min Ra=R1(12.2)+1.15mm

----------

0000001601 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=8.5+-0.1mm

----------

----------

N1=325r/min Ra=8.5+-0.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=4deg

----------

a=(50deg)

----------

aa=4deg

----------

a=(50deg)

Information:

3114 ATAAC Engine Model Views

Oil Filter (1), Fan Pulley & Bearing Assembly (2), Thermostat Housing (3), Alternator (4), Turbocharger (5), Electric Starting Motor (6), Crankshaft Pulley (7), Water Pump (8), Oil Level Gage (Dipstick) (9), Oil Drain Plug (10), Fuel Transfer Pump and Governor (11), Air Compressor (12), Oil Filler (13), Fuel Filter (14), Air Cleaner with Restriction Gauge (15), Lift Eye (16), Fuel Priming Pump (17), Crankcase Breather (18) and Power Steering Pump (19).3116 ATAAC Engine Model Views

LEFT SIDE VIEW

Fan Pulley & Bearing Assembly (1), Thermostat Housing (2), Crankshaft Vibration Damper & Pulley (3116 ONLY) (3), Oil Level Gage (Dipstick) (4), Oil Drain Plug (5), Fuel Transfer Pump and Governor (6), Air Compressor (7), Oil Filler (8), Fuel Filter (9), Lift Eye (10), Fuel Priming Pump (11), Crankcase Breather (12) and Power Steering Pump (13), Fuel Filter Bleed Screw (14).Engine Information

The engines described in this Manual are the 3114 and 3116 ATAAC Diesel Truck engines designed primarily for on-highway medium duty applications.3114 Engine

The Caterpillar 3114 Truck (Vehicular) Engine has a 4.4 liter (269 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 4 cylinder with direct injection. 3116 Engine

The Caterpillar 3116 Truck (Vehicular) Engine has a 6.6 liter (403 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 6 cylinder with direct injection. All Engines

3114 & 3116 Cylinder and Valve Location Rated speed for the Truck (Vehicular) Engine, turbocharged with Air-to-Air Aftercooling System (ATAAC), equipped with a mechanical governor and high pressure injection fuel system is 2600 rpm. Refer to the Information Plate or Caterpillar for information regarding your engine.The cooling system consists of a belt driven centrifugal pump, with a thermostat which regulates engine coolant temperature, electric fan clutch, an oil cooler and a radiator incorporating a shunt system.The engine lubricating oil (both cooled and filtered) is supplied by a gear-type pump and bypass valves provide unrestricted flow of oil to engine parts when oil viscosity is high, or if the oil cooler or filter elements become plugged.To obtain maximum efficiency and lowest cost to operate and own your Caterpillar engine, use only recommended fuels and lubricants and follow the maintenance recommendations in the Maintenance Schedule which can be found in the Maintenance Section of this Manual.Serial Number Plate and Information Plate Locations

Engine Identification

Caterpillar engines are identified with Serial Numbers, Performance Specification Numbers (fuel system settings) and Arrangement Numbers. In some cases Modification Numbers are also used. These numbers are shown on the Serial Number Plate (1) mounted on the engine.Caterpillar needs all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Serial Number Plate

There are two possible locations for the Serial Number Plate (1).Some engines have the plate on the left side of the engine and some engines will have the

Oil Filter (1), Fan Pulley & Bearing Assembly (2), Thermostat Housing (3), Alternator (4), Turbocharger (5), Electric Starting Motor (6), Crankshaft Pulley (7), Water Pump (8), Oil Level Gage (Dipstick) (9), Oil Drain Plug (10), Fuel Transfer Pump and Governor (11), Air Compressor (12), Oil Filler (13), Fuel Filter (14), Air Cleaner with Restriction Gauge (15), Lift Eye (16), Fuel Priming Pump (17), Crankcase Breather (18) and Power Steering Pump (19).3116 ATAAC Engine Model Views

LEFT SIDE VIEW

Fan Pulley & Bearing Assembly (1), Thermostat Housing (2), Crankshaft Vibration Damper & Pulley (3116 ONLY) (3), Oil Level Gage (Dipstick) (4), Oil Drain Plug (5), Fuel Transfer Pump and Governor (6), Air Compressor (7), Oil Filler (8), Fuel Filter (9), Lift Eye (10), Fuel Priming Pump (11), Crankcase Breather (12) and Power Steering Pump (13), Fuel Filter Bleed Screw (14).Engine Information

The engines described in this Manual are the 3114 and 3116 ATAAC Diesel Truck engines designed primarily for on-highway medium duty applications.3114 Engine

The Caterpillar 3114 Truck (Vehicular) Engine has a 4.4 liter (269 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 4 cylinder with direct injection. 3116 Engine

The Caterpillar 3116 Truck (Vehicular) Engine has a 6.6 liter (403 inch3) displacement, with 105 mm (4.13 inch) bore and 127 mm (5.0 inch) stroke. The engine is a four stroke cycle, in-line 6 cylinder with direct injection. All Engines

3114 & 3116 Cylinder and Valve Location Rated speed for the Truck (Vehicular) Engine, turbocharged with Air-to-Air Aftercooling System (ATAAC), equipped with a mechanical governor and high pressure injection fuel system is 2600 rpm. Refer to the Information Plate or Caterpillar for information regarding your engine.The cooling system consists of a belt driven centrifugal pump, with a thermostat which regulates engine coolant temperature, electric fan clutch, an oil cooler and a radiator incorporating a shunt system.The engine lubricating oil (both cooled and filtered) is supplied by a gear-type pump and bypass valves provide unrestricted flow of oil to engine parts when oil viscosity is high, or if the oil cooler or filter elements become plugged.To obtain maximum efficiency and lowest cost to operate and own your Caterpillar engine, use only recommended fuels and lubricants and follow the maintenance recommendations in the Maintenance Schedule which can be found in the Maintenance Section of this Manual.Serial Number Plate and Information Plate Locations

Engine Identification

Caterpillar engines are identified with Serial Numbers, Performance Specification Numbers (fuel system settings) and Arrangement Numbers. In some cases Modification Numbers are also used. These numbers are shown on the Serial Number Plate (1) mounted on the engine.Caterpillar needs all of these numbers to determine which components were included on the engine when it was assembled at the factory. This permits accurate identification of replacement part numbers.Serial Number Plate

There are two possible locations for the Serial Number Plate (1).Some engines have the plate on the left side of the engine and some engines will have the

Have questions with 106873-7050?

Group cross 106873-7050 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

106873-7050

INJECTION-PUMP ASSEMBLY