Information injection-pump assembly

ZEXEL

106873-3690

1068733690

HINO

220401200A

220401200a

Rating:

Cross reference number

ZEXEL

106873-3690

1068733690

HINO

220401200A

220401200a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.2

4.14

4.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

131

128

134

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8+-0.5

Pump speed

r/min

460

460

460

Average injection quantity

mm3/st.

13.3

12.3

14.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

131

129

133

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

121.5

115.5

127.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

760--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

710

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

(770)

Advance angle

deg.

2.25

1.95

2.55

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

(900)

Advance angle

deg.

2.25

1.95

2.55

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_05

Pump speed

r/min

1050+50

Advance angle

deg.

6.75

6.45

7.05

Remarks

Finish

Finish

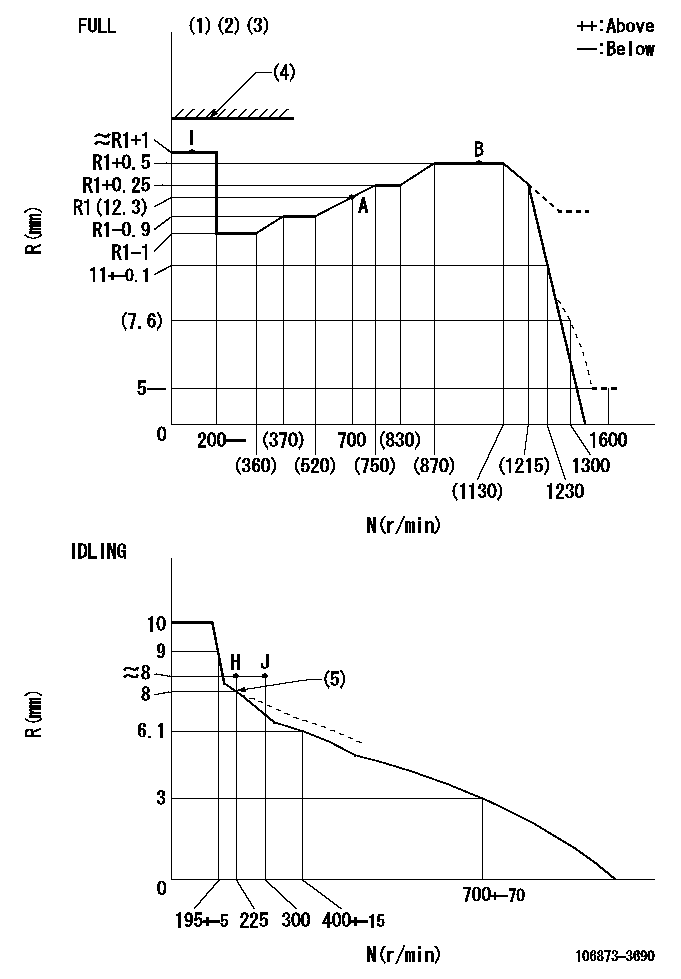

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set stop lever before governor adjustment. [When setting stop lever after governor adjustment, confirm that point I (Ra) can be obtained at full setting.]

(4)Stop lever's normal position setting: equivalent to RA

(5)Damper spring setting: DL

----------

T1=AF07 Ra=R1+1mm RA=17.5mm DL=7.9-0.1mm

----------

----------

T1=AF07 Ra=R1+1mm RA=17.5mm DL=7.9-0.1mm

----------

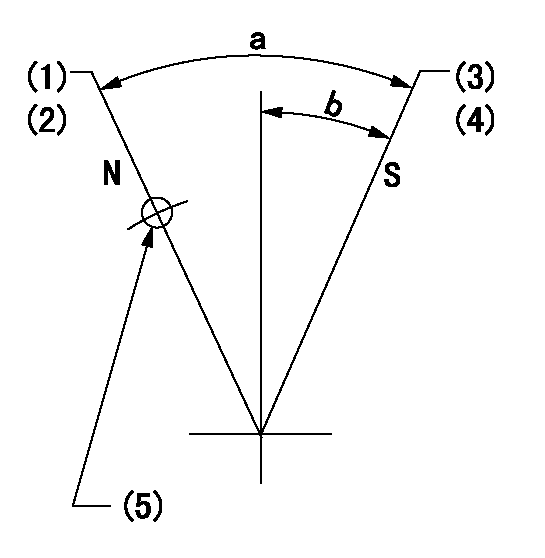

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=94mm

----------

a=17deg+-5deg b=(41.5deg)+-3deg

----------

aa=94mm

----------

a=17deg+-5deg b=(41.5deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Set the stopper screw. (After setting, apply red paint.)

(3)Rack position = bb (speed = cc)

(4)Set the stopper screw. (After setting, apply red paint.)

(5)Use the hole above R = dd

----------

aa=(17.5)mm bb=1+-0.3mm cc=0r/min dd=35mm

----------

a=35deg+-5deg b=29.5deg+-5deg

----------

aa=(17.5)mm bb=1+-0.3mm cc=0r/min dd=35mm

----------

a=35deg+-5deg b=29.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Under the Hood Inspection

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts and trash build-up. Remove trash build-up and have repairs made as needed.Perform required Daily maintenance before starting the engine.

Each time any significant quantity of oil (or other fluid) is spilled on or near the engine it should be cleaned up. Accumulated grease and oil on an engine is a fire hazard. Remove this debris with steam cleaning or high pressure water at PM Level 2 or every 6000 hours.Wipe clean all fittings, caps and plugs before servicing.

Starting the Engine

Do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.If equipped with an electrically or fuel ignited manifold heater, DO NOT use ether.

Startability will be improved at temperatures below +32°F (0°C) by the use of a starting aid (ether) or use of a cylinder block coolant heater or other means to heat the crankcase oil. This will help alleviate white smoke and misfire during cold weather start-up.Use ether when temperatures are below 32°F (0°C) for cold weather starting purposes only.

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether can cause piston and ring damage.Use ether for cold starting purposes only.

If the engine fails to start within 30 seconds, release the starter switch and wait two minutes to allow the starter motor to cool before using it again.Start the engine using the following procedure:1. Place the transmission in NEUTRAL and disengage the flywheel clutch (if equipped) to remove the transmission drag and prevent movement of the truck.Depressing the clutch in cold weather can mean the difference between starting and not starting. Depressing the clutch in warm weather produces faster starts and reduces battery drain.2. Turn the ignition switch to the ON position and push the crank button or turn the ignition switch to the START position.3. Crank the engine. If the engine fails to start in 30 seconds, release the starting (ignition) switch and wait two minutes to allow the starter motor to cool before using it again.

Do not increase engine speed until the oil pressure gauge indicates normal. Oil pressure should raise within 15 seconds after the engine starts.If oil pressure is not indicated on gauge within 15 seconds, do not drive the truck. Stop the engine, investigate and correct the cause.

4. Allow the engine to idle three to five minutes, or until the water temperature gauge has begun to rise. Check all gauges during the warm-up period.5. Check fuel level gauge. Do not fill fuel tank to top. Fuel expands as it gets warm and may overflow.Starting With Jumper Cables

When boost starting an engine, follow the instructions to properly start the engine. This engine may be equipped with a 12 or 24 volt starting system. Use only

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn belts and trash build-up. Remove trash build-up and have repairs made as needed.Perform required Daily maintenance before starting the engine.

Each time any significant quantity of oil (or other fluid) is spilled on or near the engine it should be cleaned up. Accumulated grease and oil on an engine is a fire hazard. Remove this debris with steam cleaning or high pressure water at PM Level 2 or every 6000 hours.Wipe clean all fittings, caps and plugs before servicing.

Starting the Engine

Do not store starting fluid containers in the cab. Failure to do so, could result in an explosion and/or fire and possible personal injury.If equipped with an electrically or fuel ignited manifold heater, DO NOT use ether.

Startability will be improved at temperatures below +32°F (0°C) by the use of a starting aid (ether) or use of a cylinder block coolant heater or other means to heat the crankcase oil. This will help alleviate white smoke and misfire during cold weather start-up.Use ether when temperatures are below 32°F (0°C) for cold weather starting purposes only.

When using starting fluid, follow the manufacturer's instructions carefully, use it sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether can cause piston and ring damage.Use ether for cold starting purposes only.

If the engine fails to start within 30 seconds, release the starter switch and wait two minutes to allow the starter motor to cool before using it again.Start the engine using the following procedure:1. Place the transmission in NEUTRAL and disengage the flywheel clutch (if equipped) to remove the transmission drag and prevent movement of the truck.Depressing the clutch in cold weather can mean the difference between starting and not starting. Depressing the clutch in warm weather produces faster starts and reduces battery drain.2. Turn the ignition switch to the ON position and push the crank button or turn the ignition switch to the START position.3. Crank the engine. If the engine fails to start in 30 seconds, release the starting (ignition) switch and wait two minutes to allow the starter motor to cool before using it again.

Do not increase engine speed until the oil pressure gauge indicates normal. Oil pressure should raise within 15 seconds after the engine starts.If oil pressure is not indicated on gauge within 15 seconds, do not drive the truck. Stop the engine, investigate and correct the cause.

4. Allow the engine to idle three to five minutes, or until the water temperature gauge has begun to rise. Check all gauges during the warm-up period.5. Check fuel level gauge. Do not fill fuel tank to top. Fuel expands as it gets warm and may overflow.Starting With Jumper Cables

When boost starting an engine, follow the instructions to properly start the engine. This engine may be equipped with a 12 or 24 volt starting system. Use only