Information injection-pump assembly

BOSCH

9 400 611 029

9400611029

ZEXEL

106873-3532

1068733532

HINO

220009381A

220009381a

Rating:

Service parts 106873-3532 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2741B

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/24.5{250}

14.

NOZZLE

Include in #1:

106873-3532

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 611 029

9400611029

ZEXEL

106873-3532

1068733532

HINO

220009381A

220009381a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0020

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.2

4.14

4.2

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.5

137.5

141.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

137

134

140

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

8.35+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

132.5

124.5

140.5

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

7.5

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

109.5

104.5

114.5

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

3.8+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

12

9

15

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_06

Adjusting point

G

Rack position

9+-0.1

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

156.5

150.5

162.5

Fixing the lever

*

Remarks

Startup boost setting

Startup boost setting

Injection quantity adjustment_07

Adjusting point

H

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

160

160

200

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

570--

Advance angle

deg.

0

0

0

Load

0/5

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

520

Advance angle

deg.

0.3

Load

0/5

Timer adjustment_03

Pump speed

r/min

(550)

Advance angle

deg.

2

1.7

2.3

Load

0/5

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

2

1.7

2.3

Load

4/5

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

6.75

6.45

7.05

Load

5/5

Remarks

Finish

Finish

Test data Ex:

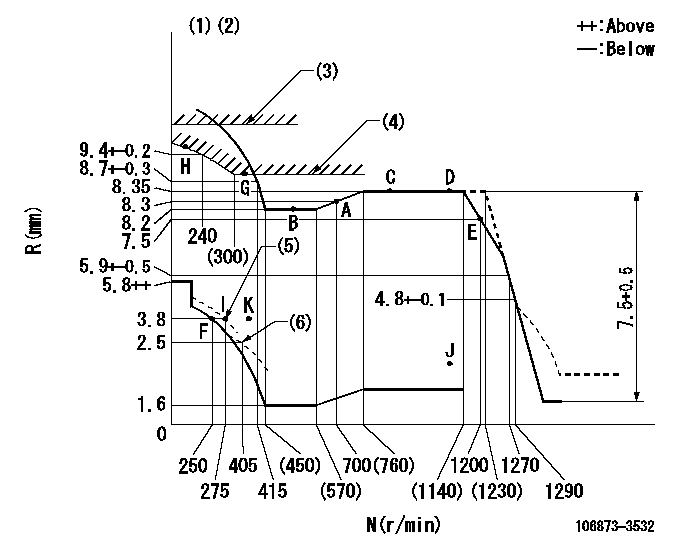

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(3)Stop lever's normal position setting: R2

(4)Excess fuel setting for starting: SXL

(5)When air cylinder is operating.

(6)Damper spring setting

----------

N1=300r/min R1=3.8mm N2=1100r/min Q1=3mm3/st R2=12+0.5mm SXL=9+-0.1mm

----------

----------

N1=300r/min R1=3.8mm N2=1100r/min Q1=3mm3/st R2=12+0.5mm SXL=9+-0.1mm

----------

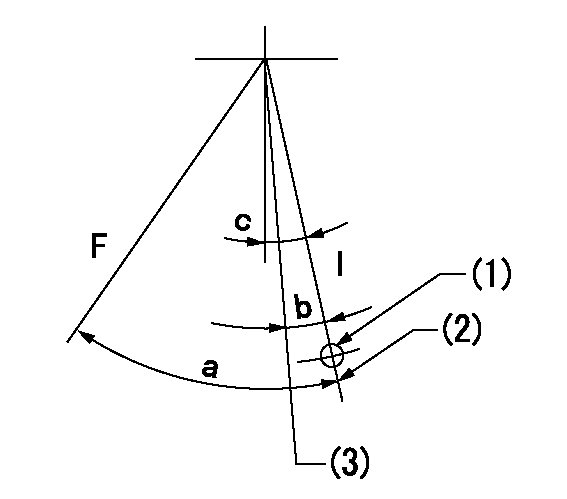

Speed control lever angle

F:Full speed

----------

----------

a=20.5deg+-5deg

----------

----------

a=20.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Set point I (at air cylinder operation)

----------

aa=90mm

----------

a=35deg+-3deg b=(1deg)+-3deg c=10deg+-5deg

----------

aa=90mm

----------

a=35deg+-3deg b=(1deg)+-3deg c=10deg+-5deg

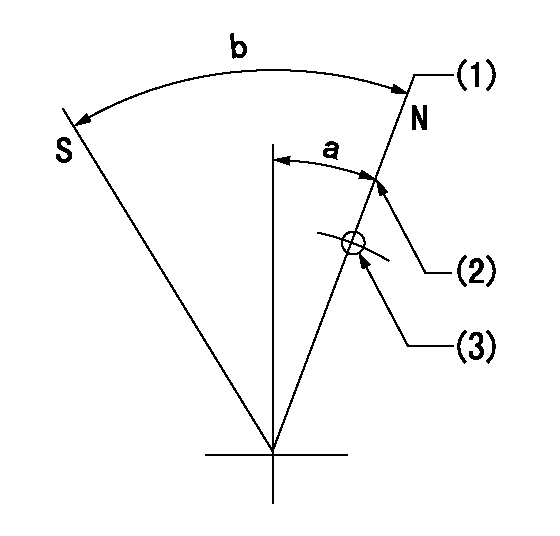

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa (set before setting excess fuel for starting)

(2)Set the stopper bolt (apply red paint).

(3)Use the pin at R = bb

----------

aa=12+0.5mm bb=37mm

----------

a=20deg+-5deg b=35deg+-5deg

----------

aa=12+0.5mm bb=37mm

----------

a=20deg+-5deg b=35deg+-5deg

0000001501 LEVER

1. Air cylinder adjustment

(1)With the load lever in the idle position, temporarily set the distance between the load lever A and the air cylinder D at approximately L.

(2)Set N1 and apply P1 to the air cylinder D.

(3)Adjust set bolt (D) to obtain R1 at the same speed.

(4)Lock using nut C.

(5)Apply positive pressure several times.

(6)Confirm that the load lever A returns to the idling position N2 at pressure P2.

(7)Also at P1 confirm R1 (N1).

----------

L=5mm R1=3.8mm N1=275r/min N2=250r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

----------

L=5mm R1=3.8mm N1=275r/min N2=250r/min P1=392+98kPa(4+1kgf/cm2) P2=0kPa(0kgf/cm2)

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Lubricant Information

Certain abbreviations follow Society of Automotive Engineers (SAE) J754 nomenclature and some classifications follow SAE J183 abbreviations. The MIL specifications are U.S.A. Military Specifications. The CCMC refers to an organization of major European manufacturers responsible for defining engine oil performance specifications. The definitions other than Caterpillar's will be of assistance in purchasing lubricants. Recommended oil viscosities can be found in the Lubricant Viscosities chart in this publication.Grease is classified by the National Lubricating Grease Institute (NLGI) based on ASTM D217-68 Worked Penetration characteristics which are given a defined consistency number.A new oil performance category has been released by the American Petroleum Institute (API) for the diesel engine oil and by Caterpillar for engine oil. The new category is:* API CF-4 (engine oil)The API CF-4 has become the new category for the API CE type oils. The performance tests for this oil will be the new Cat 1K single cylinder oil test engine and other engine tests which are presently part of the CE oil evaluation.Engine Lubricant Specification

Caterpillar has an oil formulation to provide maximum performance and life for your on-highway diesel truck engine. Cat Engine Oils are offered in a full line of appropriate single and multi-viscosity grades to meet the performance and ambient temperature requirements for heavy duty diesel truck engines.Caterpillar recommends the following specifications to achieve the maximum engine life and performance with your on-highway diesel truck engine.* Caterpillar Engine Oil Cat Diesel Engine Oil-DEO (CF-4)Cat Diesel Engine Oil-DEO (CD)Cat Oils are performance rated as SAE 10W30 - API CF-4 (new category); API CE;SAE 15W40 - API CF-4 (new category); API CE;API CD-IISAE 30 - API CD-II; API CDCat Engine Oil is currently being used for factory fill for engines and is offered by Caterpillar dealers for continued refill use. Consult your Caterpillar dealer for this Cat Oil.Cat Diesel Engine Oil DEO (CF-4) is an oil formulated with strong dispersancy effectiveness along with sufficient alkalinity and low sulfated ash level for performance requirements of engine operation in today's and future designs. Oils meeting the American Petroleum Institute (API) CF-4 performance category possess the properties to operate effectively at the higher piston temperatures of some current and future engines.The DEO (CF-4) oil type to be selected will depend on the engine type, fuel sulfur, application and customer preference.The DEO (CF-4) oil is blended in viscosity grades of SAE 10W30 and 15W40. Multi-grade oils are required because of the significantly lower oil consumption of multi-viscosity oils as compared to single grades. Oil consumption and piston crownland deposits are very important in the engine tests used to evaluate oil performance. This oil is also qualified as API SG which allows its use in gasoline engine applications requiring this performance rating.Cat Diesel Engine Oil DEO (CD) is blended with a diesel engine type additive with strong detergency effectiveness. This oil has a higher alkalinity (13.5 TBN) than many oils for the neutralization of wear causing combustion products and provides additional protection for higher fuel sulfur. This oil is blended

Certain abbreviations follow Society of Automotive Engineers (SAE) J754 nomenclature and some classifications follow SAE J183 abbreviations. The MIL specifications are U.S.A. Military Specifications. The CCMC refers to an organization of major European manufacturers responsible for defining engine oil performance specifications. The definitions other than Caterpillar's will be of assistance in purchasing lubricants. Recommended oil viscosities can be found in the Lubricant Viscosities chart in this publication.Grease is classified by the National Lubricating Grease Institute (NLGI) based on ASTM D217-68 Worked Penetration characteristics which are given a defined consistency number.A new oil performance category has been released by the American Petroleum Institute (API) for the diesel engine oil and by Caterpillar for engine oil. The new category is:* API CF-4 (engine oil)The API CF-4 has become the new category for the API CE type oils. The performance tests for this oil will be the new Cat 1K single cylinder oil test engine and other engine tests which are presently part of the CE oil evaluation.Engine Lubricant Specification

Caterpillar has an oil formulation to provide maximum performance and life for your on-highway diesel truck engine. Cat Engine Oils are offered in a full line of appropriate single and multi-viscosity grades to meet the performance and ambient temperature requirements for heavy duty diesel truck engines.Caterpillar recommends the following specifications to achieve the maximum engine life and performance with your on-highway diesel truck engine.* Caterpillar Engine Oil Cat Diesel Engine Oil-DEO (CF-4)Cat Diesel Engine Oil-DEO (CD)Cat Oils are performance rated as SAE 10W30 - API CF-4 (new category); API CE;SAE 15W40 - API CF-4 (new category); API CE;API CD-IISAE 30 - API CD-II; API CDCat Engine Oil is currently being used for factory fill for engines and is offered by Caterpillar dealers for continued refill use. Consult your Caterpillar dealer for this Cat Oil.Cat Diesel Engine Oil DEO (CF-4) is an oil formulated with strong dispersancy effectiveness along with sufficient alkalinity and low sulfated ash level for performance requirements of engine operation in today's and future designs. Oils meeting the American Petroleum Institute (API) CF-4 performance category possess the properties to operate effectively at the higher piston temperatures of some current and future engines.The DEO (CF-4) oil type to be selected will depend on the engine type, fuel sulfur, application and customer preference.The DEO (CF-4) oil is blended in viscosity grades of SAE 10W30 and 15W40. Multi-grade oils are required because of the significantly lower oil consumption of multi-viscosity oils as compared to single grades. Oil consumption and piston crownland deposits are very important in the engine tests used to evaluate oil performance. This oil is also qualified as API SG which allows its use in gasoline engine applications requiring this performance rating.Cat Diesel Engine Oil DEO (CD) is blended with a diesel engine type additive with strong detergency effectiveness. This oil has a higher alkalinity (13.5 TBN) than many oils for the neutralization of wear causing combustion products and provides additional protection for higher fuel sulfur. This oil is blended