Information injection-pump assembly

BOSCH

9 400 618 428

9400618428

ZEXEL

106873-3250

1068733250

HINO

220204300A

220204300a

Rating:

Cross reference number

BOSCH

9 400 618 428

9400618428

ZEXEL

106873-3250

1068733250

HINO

220204300A

220204300a

Zexel num

Bosch num

Firm num

Name

106873-3250

9 400 618 428

220204300A HINO

INJECTION-PUMP ASSEMBLY

EF750T K

EF750T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

135.5

133.5

137.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.2+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

14

11

17

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

172

172

192

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2.5

2.2

2.8

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

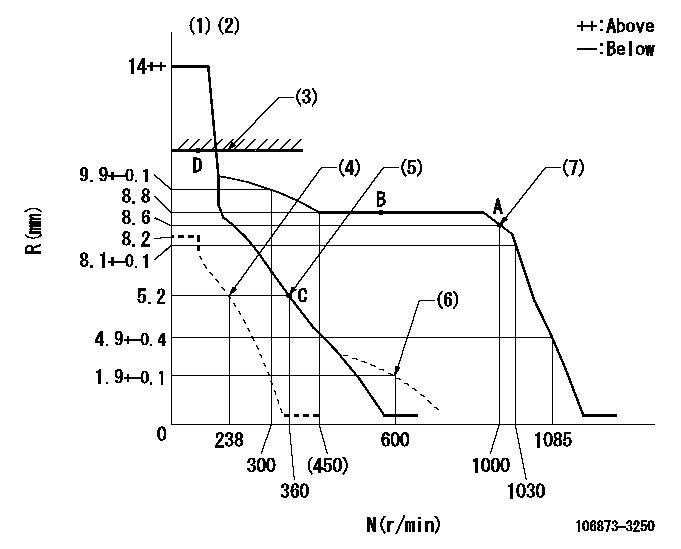

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Damper spring setting

(7)Set the torque spring.

----------

K=6

----------

----------

K=6

----------

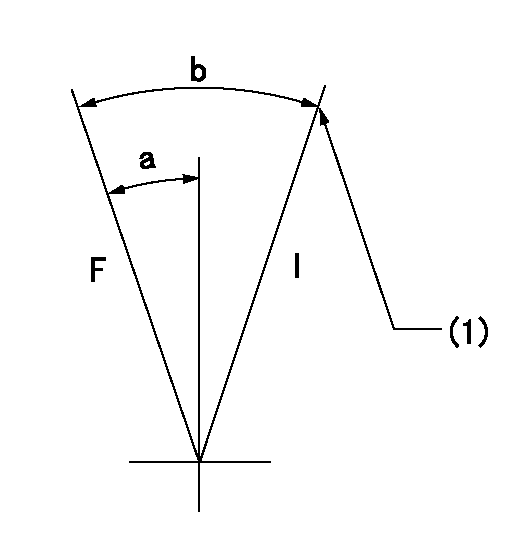

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=0deg+-5deg b=17deg+-5deg

----------

----------

a=0deg+-5deg b=17deg+-5deg

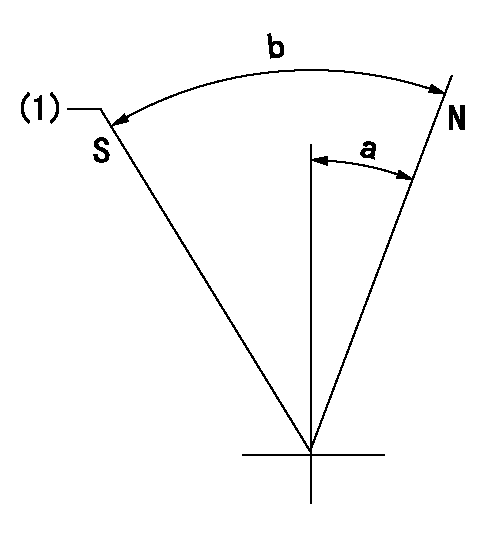

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa or less, pump speed bb

----------

aa=4.7mm bb=0r/min

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

aa=4.7mm bb=0r/min

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

The engine can be turbocharged and jacket water aftercooled (TA), or turbocharged and air-to-air aftercooled (ATAAC) with direct fuel injection.The 3406B PEEC is an electronically controlled, mechanically actuated unit injector diesel engine. Timing advance is achieved by precise control of injector firing. Engine speed is controlled by adjusting the firing duration. A pulse wheel provides information to the fuel cooled ECM (Electronic Control Module) for detection of cylinder position and engine speed.The programmable electronic engine control (PEEC) system was designed to provide electronic governing, automatic air-fuel ratio control, torque rise shaping, injection timing control and system diagnostics. Additional benefits such as cruise control, vehicle speed limiting, low and high gears engine rpm limiting (progressive shift engine speed control), PTO governor, data link and multi-torque ratings provide for additional engine fuel economy, driver comfort and serviceability.The fuel system is a mechanically actuated, electronically controlled unit injector combining the pumping, electronic fuel metering and injecting elements in a single unit to produce higher injection pressures. High injection pressures help to reduce fuel consumption and particulate emissions.The use of this type of unit injector provides total electronic control of injection timing. The injection timing is varied as a function of engine operating conditions. This optimizes the engine's performance for starting, emissions, noise, fuel consumption and driveability.A full range electronic governor controls the fuel injection pump output to maintain the engine rpm desired by the PEEC system. The governor functions like the Caterpillar mechanical governor in the mid-range, but includes additional features. These include programmable isochronous low idle and 20 rpm governor overrun.Individual injection pumps, one for each cylinder, meter and pump fuel under high pressure to an injection valve for eacy cylinder. Automatic timing advance provides the best fuel injection timing over the full range of engine speed.The 3406B PEEC has built-in diagnostics to assure that all components are functioning and operating properly. In the event of a system component deviation from programmed limits, the operator will be alerted to the condition by a dashboard mounted "Check Engine" light.A Caterpillar service tool is required to read the numerical code of the faulty component. Intermittent faults are logged and stored in the system memory.The cooling system consists of a gear driven centrifugal pump, with one thermostat which regulates the engine coolant temperature, an oil cooler and a radiator incorporating a shunt system.The engine lubricating oil, which is both cooled and filtered, is supplied by a gear-type pump. Bypass valves provide unrestricted flow of lubrication oil to the engine parts when oil viscosity is high, or if either the oil cooler or the oil filter elements should become plugged. Multi-Torque Rating (if equipped)This feature provides higher torque levels and better fuel economy while in top gear only. The 3406B PEEC electronics is able to determine when the vehicle is in top gear by calculating the engine rpm/vehicle speed ratio. A ratio of less than 26.6 will provide higher torque.Example: 1450 rpm/60 mph (96 km/h)=24.2The benefits of Multi-Torque are: * driver feel* less shifting

Have questions with 106873-3250?

Group cross 106873-3250 ZEXEL

Hino

Hino

Hino

106873-3250

9 400 618 428

220204300A

INJECTION-PUMP ASSEMBLY

EF750T

EF750T