Information injection-pump assembly

ZEXEL

106873-3230

1068733230

HINO

220008140B

220008140b

Rating:

Service parts 106873-3230 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2480E

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/24.5{250}

14.

NOZZLE

Include in #1:

106873-3230

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106873-3230

1068733230

HINO

220008140B

220008140b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

-

Rack position

13.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

150

147

153

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

8.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

11

8

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

150

148

152

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

142.5

136.5

148.5

Fixing the lever

*

Timer adjustment

Pump speed

r/min

600--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

550

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

(620)

Advance angle

deg.

1

0.7

1.3

Timer adjustment_04

Pump speed

r/min

980+50

Advance angle

deg.

1

0.7

1.3

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

Test data Ex:

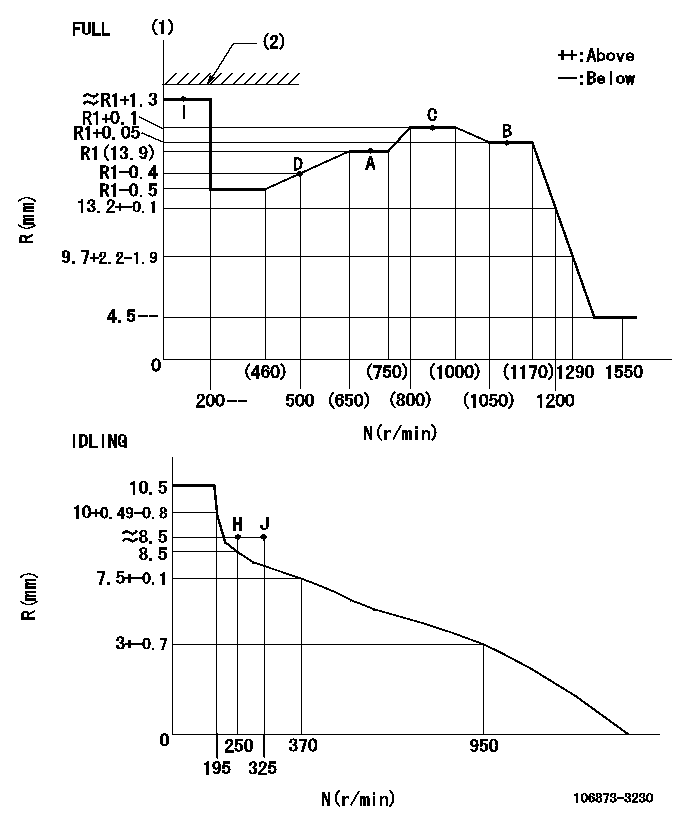

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Stop lever's normal position setting: R1 (Set the stop lever's normal setting before setting the torque cam.)

----------

T1=AA19 R1=18+-0.3mm

----------

----------

T1=AA19 R1=18+-0.3mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=79mm

----------

a=12deg+-5deg b=27deg+-3deg

----------

aa=79mm

----------

a=12deg+-5deg b=27deg+-3deg

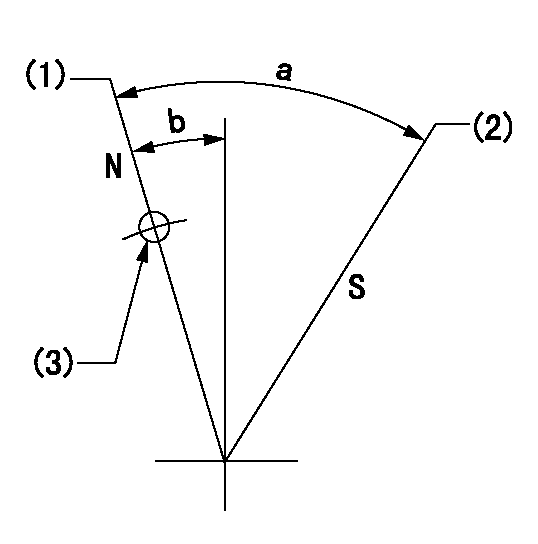

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set stopper screw so that rack position = aa (after setting, apply red paint).

(2)Set stopper screw so that rack position = bb (after setting apply red paint).

(3)Use the hole above R = cc

----------

aa=18+-0.3mm bb=1.5+-0.3mm cc=35mm

----------

a=35deg+-5deg b=20deg+-5deg

----------

aa=18+-0.3mm bb=1.5+-0.3mm cc=35mm

----------

a=35deg+-5deg b=20deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Until recently, engine maintenance and repair management involved changing the oil when it was convenient and repairing the engine when it was damaged. This seemed to be the accepted way of managing a maintenance operation. However, due to a variety of circumstances, freight hauling jobs became increasingly more competitive. This competitiveness caused users to look for ways to prolong equipment life and lower operating costs so that they could be competitive when bidding jobs.To assist Caterpillar Engine users in prolonging engine life and reducing operating costs, the Value Planned Repair approach to engine service was developed.The Value Planned Repair approach can be tailored for any engine. This approach, when properly structured, outlines every maintenance and repair service required to support an engine from the day it enters service until the day it is retired.To ensure the repair is performed efficiently and expediently, the Value Planned Repair concept approaches a given repair in three basic steps: 1. Repair determination2. Evaluation of repair options3. Selection of the most appropriate option* Services required to maintain an engine at optimum efficiency.* Scheduled maintenance, repairs and overhauls to minimize unscheduled downtime.* Preplanned repairs and overhauls that can be flat-rated, putting you in charge of costs.* Repair or overhaul options designed to restore the engine to proper operating condition.* Repair or overhaul options designed to renew the engine if a failure has occurred.Part of the Value Planned Repair approach is the repair before failure concept. The objective of the repair before failure concept is to repair the engine before a failure takes place. The fact that a failure has not taken place makes the repair before failure concept more economical since a high degree of parts such as pistons, liners, valves, etc., and major castings such as cylinder blocks, cylinder heads, etc., can be reused. Also, an extensive internal cleaning of the engine, which is labor intensive, is eliminated because a debris-generating failure has not taken place.The best part of the repair before failure concept is that unscheduled downtime is minimized and in most cases eliminated because the repair or overhaul can be scheduled to allow the user to adjust his operation accordingly.The overall benefit to a customer who repairs an engine before failure is that the customer and not the engine is in control of the repairs required.To stress the importance of the Value Planned Repair approach, please consider the following example that reflects the difference in the cost of a before failure repair versus the cost of an after failure repair.The cost to repair a turbocharger after it fails is approximately five times more than the cost of repairing a turbocharger before it fails.However, if parts from a damaged turbocharger enters the engine, then the cost to repair your engine could be as high as 10 times or more the cost of repairing a turbocharger before it fails.By subscribing to the Value Planned Repair approach, you can avoid spending your money on costly repairs that should have been prevented and utilize your