Information injection-pump assembly

ZEXEL

106873-3131

1068733131

HINO

220007971A

220007971a

Rating:

Cross reference number

ZEXEL

106873-3131

1068733131

HINO

220007971A

220007971a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.3

137.3

141.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.95+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

133.1

129.1

137.1

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

F

Rack position

3.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.4

7.4

13.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

139

139

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

820--

Advance angle

deg.

0.7

0.4

1

Load

4/4

Timer adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

0.7

0.4

1

Load

3/4

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

5.25

4.95

5.55

Load

4/4

Remarks

Finish

Finish

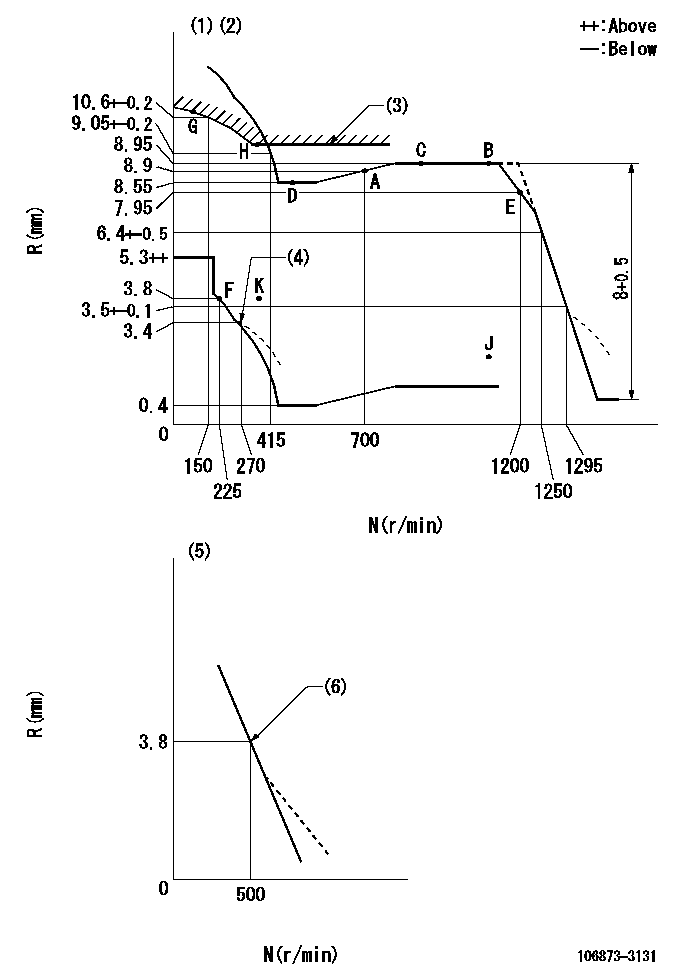

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting

(5)Variable speed specification: idling adjustment

(6)Main spring setting

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=10.25+-0.1mm

----------

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=10.25+-0.1mm

----------

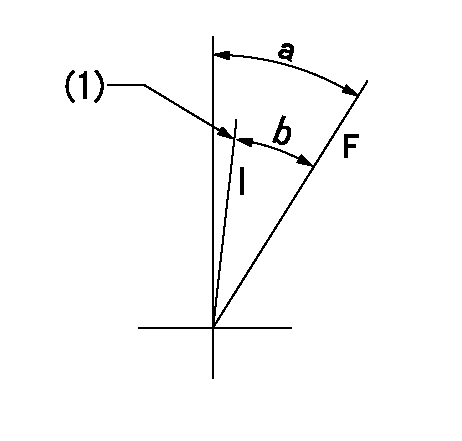

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=15.5deg+-5deg b=(14deg)+-5deg

----------

----------

a=15.5deg+-5deg b=(14deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=42mm

----------

a=39deg+-5deg b=43.5deg+-3deg

----------

aa=42mm

----------

a=39deg+-5deg b=43.5deg+-3deg

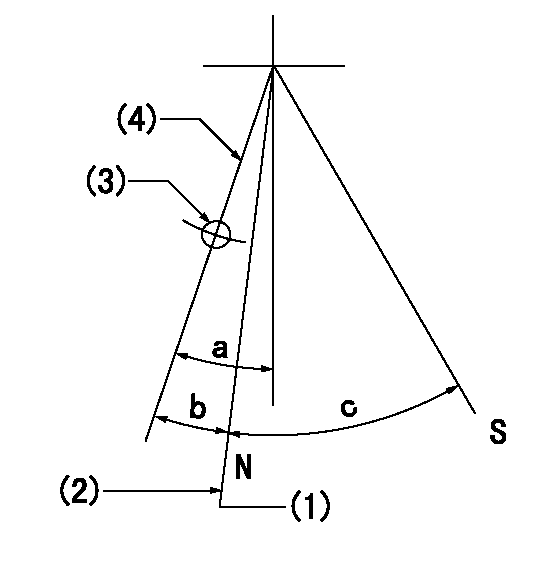

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa (at delivery), set before governor adjustment

(2)Set the stopper bolt (apply red paint).

(3)Use the pin at R = bb

(4)Lever free

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Water Pump Seal

Over concentration of coolant additive (Conditioner), mineral deposits from hard water or cooling system contamination can accelerate the wear on the water pump coolant seal. The cooling system maintenance interval provides an opportunity to inspect and replace the water pump seal if necessary to reduce coolant leakage.Dispose of used engine coolant in an environmentally correct way or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant and for information regarding disposal and recycling of used coolant.4. Clean and install all drain plugs and/or close the cooling system drain valve(s).Replace Thermostat, Gaskets and Seal

Refer to the Service Manual for detailed instructions regarding Disassembly and Assembly of the Cooling System. Repeat procedure for both thermostat housing assemblies.Replacing the thermostats prior to failure is a recommended preventive maintenance practice because it reduces the chances for cooling system problems and unscheduled downtime.

Failure to replace your thermostats on a regularly scheduled basis could cause severe engine damage.

If replacing thermostats ONLY, drain the coolant from the cooling system to a level below the thermostat housing.5. Disconnect hose assemblies from radiator and each thermostat housing assembly.6. Remove bolts and thermostat housing assembly.7. Remove the gasket, thermostat and seal from each housing.

Former thermostats may be used, if they meet test specifications as described in the Service Manual (and are not damaged or have excessive buildup of deposits).

The thermostats can be reused if they are tested and meet the test specifications in the Service Manual.Flush

8. Refill the cooling system with clean water mixed with the proper concentration (six to ten percent) of Fast Acting-Type Caterpillar Cooling System Cleaner (4C4611). Tighten cooling system vent cap. For proper cooling system maintenance cleaning, refer to label directions for the type of Caterpillar Cooling System Cleaner used in your cooling system.9. Start and run (operate) the engine to circulate fluid in the cooling system.10. Stop the engine and allow to cool. Loosen cooling system vent cap and drain plugs.11. Drain the cleaning solution. Flush the cooling system with clean water and a neutralizing solution until draining water is clear. Clean and install all drain plugs and/or close the drain valve. Sodium Carbonate crystals at a rate of 250 grams per 40 liters of water (1/2 pound per 10 U.S. gallon of water) may be used as a neutralizer. Repeat Steps 8 thru 11 if necessary until the draining water is clear.Install Thermostat

Caterpillar engines incorporate a shunt design cooling system and require operating the engine with a thermostat installed.If the thermostat is installed wrong, it will cause the engine to overheat.

Inspect gaskets before assembly and replace if worn or damaged.12. Install a new seal in each thermostat housing and install new thermostats.13. Install a new gasket and the thermostat housing on the engine cylinder head.14. Install the cooling system connections and tighten the hose or piping clamps.Fill

All water is corrosive at engine operating temperature. The cooling system

Over concentration of coolant additive (Conditioner), mineral deposits from hard water or cooling system contamination can accelerate the wear on the water pump coolant seal. The cooling system maintenance interval provides an opportunity to inspect and replace the water pump seal if necessary to reduce coolant leakage.Dispose of used engine coolant in an environmentally correct way or recycle. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant and for information regarding disposal and recycling of used coolant.4. Clean and install all drain plugs and/or close the cooling system drain valve(s).Replace Thermostat, Gaskets and Seal

Refer to the Service Manual for detailed instructions regarding Disassembly and Assembly of the Cooling System. Repeat procedure for both thermostat housing assemblies.Replacing the thermostats prior to failure is a recommended preventive maintenance practice because it reduces the chances for cooling system problems and unscheduled downtime.

Failure to replace your thermostats on a regularly scheduled basis could cause severe engine damage.

If replacing thermostats ONLY, drain the coolant from the cooling system to a level below the thermostat housing.5. Disconnect hose assemblies from radiator and each thermostat housing assembly.6. Remove bolts and thermostat housing assembly.7. Remove the gasket, thermostat and seal from each housing.

Former thermostats may be used, if they meet test specifications as described in the Service Manual (and are not damaged or have excessive buildup of deposits).

The thermostats can be reused if they are tested and meet the test specifications in the Service Manual.Flush

8. Refill the cooling system with clean water mixed with the proper concentration (six to ten percent) of Fast Acting-Type Caterpillar Cooling System Cleaner (4C4611). Tighten cooling system vent cap. For proper cooling system maintenance cleaning, refer to label directions for the type of Caterpillar Cooling System Cleaner used in your cooling system.9. Start and run (operate) the engine to circulate fluid in the cooling system.10. Stop the engine and allow to cool. Loosen cooling system vent cap and drain plugs.11. Drain the cleaning solution. Flush the cooling system with clean water and a neutralizing solution until draining water is clear. Clean and install all drain plugs and/or close the drain valve. Sodium Carbonate crystals at a rate of 250 grams per 40 liters of water (1/2 pound per 10 U.S. gallon of water) may be used as a neutralizer. Repeat Steps 8 thru 11 if necessary until the draining water is clear.Install Thermostat

Caterpillar engines incorporate a shunt design cooling system and require operating the engine with a thermostat installed.If the thermostat is installed wrong, it will cause the engine to overheat.

Inspect gaskets before assembly and replace if worn or damaged.12. Install a new seal in each thermostat housing and install new thermostats.13. Install a new gasket and the thermostat housing on the engine cylinder head.14. Install the cooling system connections and tighten the hose or piping clamps.Fill

All water is corrosive at engine operating temperature. The cooling system