Information injection-pump assembly

ZEXEL

106873-3103

1068733103

HINO

220007883A

220007883a

Rating:

Cross reference number

ZEXEL

106873-3103

1068733103

HINO

220007883A

220007883a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.3

137.3

141.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.95+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

133.1

129.1

137.1

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

F

Rack position

3.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.4

7.4

13.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

139

139

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

820--

Advance angle

deg.

0.7

0.4

1

Load

4/4

Timer adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

0.7

0.4

1

Load

3/4

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

5.25

4.95

5.55

Load

4/4

Remarks

Finish

Finish

Test data Ex:

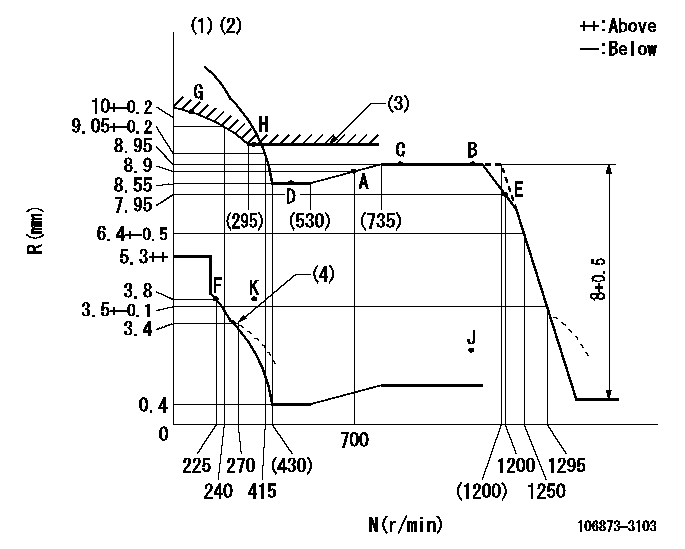

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=9.45+-0.1mm

----------

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=9.45+-0.1mm

----------

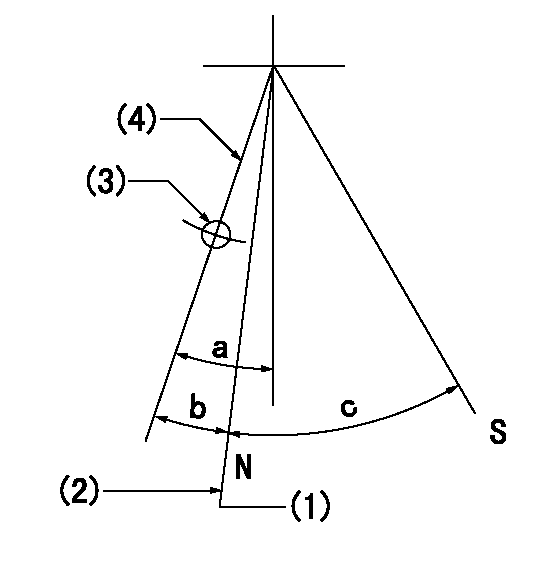

Speed control lever angle

F:Full speed

----------

----------

a=15.5deg+-5deg

----------

----------

a=15.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=39mm

----------

a=39deg+-5deg b=43.5deg+-3deg

----------

aa=39mm

----------

a=39deg+-5deg b=43.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa (at delivery), set before governor adjustment

(2)Set the stopper bolt (apply red paint).

(3)Use the pin at R = bb

(4)Lever free

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Diagnostic Lamp

A DIAGNOSTIC lamp may be included with your engine package. The DIAGNOSTIC lamp indicates an engine diagnostic condition or an electronic governing/control system fault. In most cases a diagnostic code will be stored in permanent memory within the ECM. The diagnostic code can be retrieved by either of two methods; 1) electronic service tool or 2) use the DIAGNOSTIC lamp.The engine may be equipped with a DIAGNOSTIC lamp that automatically flashes an active fault code when there is power to the ECM. ACTIVE Codes - represent problem(s) that currently exist and should be investigated first. If a code is active, the Diagnostic lamp will illuminate and blink every five seconds. LOGGED Codes - represent intermittent problem(s) which may have been temporary or repaired since the time code was logged. These codes do not indicate a repair is needed, but instead are guides or signals when an intermittent situation exists, which could be used to troubleshoot and analyze potential problems. In addition, some LOGGED Codes record events and performance history, rather than problems and/or failures.Diagnostic Flash Code Retrieval

If the DIAGNOSTIC lamp is ON during engine operation, the system has detected a system fault. Use the DIAGNOSTIC lamp or electronic service tool to identify the diagnostic code.The DIAGNOSTIC lamp will illuminate (ON) and blink every five seconds whenever a diagnostic fault is detected by the ECM. The lamp should also illuminate (ON) whenever the START switch is turned ON, but the engine is not running. This condition will test whether the lamp is operating correctly. The DIAGNOSTIC lamp will illuminate for five seconds and turn OFF for an intermittent fault (stays ON ONLY if there is an Active Diagnostic Code).If the DIAGNOSTIC lamp comes ON and stays ON after initial start-up, the ECM has detected a system fault. Use the lamp or the ECAP service tool to determine the diagnostic code.The DIAGNOSTIC lamp can be used to communicate the specific diagnostic fault. With the switch depressed, the DIAGNOSTIC lamp will begin to flash. The sequence of flashes represents the system diagnostic message. Count the first sequence of flashes to determine the first digit of the diagnostic code. After a two second pause, the second sequence of flashes will identify the second digit of the diagnostic code. Any additional diagnostic codes will follow (after a pause) and will be displayed in the same manner.Refer to the Electronic Troubleshooting Manual for troubleshooting ELECTRONIC SYSTEM problems, or for further information or assistance, contact your Caterpillar dealer. Permanent Fault Logging

The system provides Permanent Fault Logging. When the ECM generates a diagnostic code, it will log the code in permanent memory. The logged codes can then be retrieved using an electronic service tool.Intermittent Fault

If the diagnostic lamp comes ON during engine operation, and then goes out, an intermittent fault may be occurring. The electronic control engine system is equipped with permanent fault logging. It will automatically log (or remember) most intermittent faults to help a service technician diagnose an engine problem.If there are no

A DIAGNOSTIC lamp may be included with your engine package. The DIAGNOSTIC lamp indicates an engine diagnostic condition or an electronic governing/control system fault. In most cases a diagnostic code will be stored in permanent memory within the ECM. The diagnostic code can be retrieved by either of two methods; 1) electronic service tool or 2) use the DIAGNOSTIC lamp.The engine may be equipped with a DIAGNOSTIC lamp that automatically flashes an active fault code when there is power to the ECM. ACTIVE Codes - represent problem(s) that currently exist and should be investigated first. If a code is active, the Diagnostic lamp will illuminate and blink every five seconds. LOGGED Codes - represent intermittent problem(s) which may have been temporary or repaired since the time code was logged. These codes do not indicate a repair is needed, but instead are guides or signals when an intermittent situation exists, which could be used to troubleshoot and analyze potential problems. In addition, some LOGGED Codes record events and performance history, rather than problems and/or failures.Diagnostic Flash Code Retrieval

If the DIAGNOSTIC lamp is ON during engine operation, the system has detected a system fault. Use the DIAGNOSTIC lamp or electronic service tool to identify the diagnostic code.The DIAGNOSTIC lamp will illuminate (ON) and blink every five seconds whenever a diagnostic fault is detected by the ECM. The lamp should also illuminate (ON) whenever the START switch is turned ON, but the engine is not running. This condition will test whether the lamp is operating correctly. The DIAGNOSTIC lamp will illuminate for five seconds and turn OFF for an intermittent fault (stays ON ONLY if there is an Active Diagnostic Code).If the DIAGNOSTIC lamp comes ON and stays ON after initial start-up, the ECM has detected a system fault. Use the lamp or the ECAP service tool to determine the diagnostic code.The DIAGNOSTIC lamp can be used to communicate the specific diagnostic fault. With the switch depressed, the DIAGNOSTIC lamp will begin to flash. The sequence of flashes represents the system diagnostic message. Count the first sequence of flashes to determine the first digit of the diagnostic code. After a two second pause, the second sequence of flashes will identify the second digit of the diagnostic code. Any additional diagnostic codes will follow (after a pause) and will be displayed in the same manner.Refer to the Electronic Troubleshooting Manual for troubleshooting ELECTRONIC SYSTEM problems, or for further information or assistance, contact your Caterpillar dealer. Permanent Fault Logging

The system provides Permanent Fault Logging. When the ECM generates a diagnostic code, it will log the code in permanent memory. The logged codes can then be retrieved using an electronic service tool.Intermittent Fault

If the diagnostic lamp comes ON during engine operation, and then goes out, an intermittent fault may be occurring. The electronic control engine system is equipped with permanent fault logging. It will automatically log (or remember) most intermittent faults to help a service technician diagnose an engine problem.If there are no