Information injection-pump assembly

ZEXEL

106873-3100

1068733100

HINO

220007880A

220007880a

Rating:

Cross reference number

ZEXEL

106873-3100

1068733100

HINO

220007880A

220007880a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.3

137.3

141.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.95+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

133.1

129.1

137.1

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

F

Rack position

3.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.4

7.4

13.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

139

139

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

820--

Advance angle

deg.

0.7

0.4

1

Load

4/4

Timer adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

0.7

0.4

1

Load

3/4

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

5.25

4.95

5.55

Load

4/4

Remarks

Finish

Finish

Test data Ex:

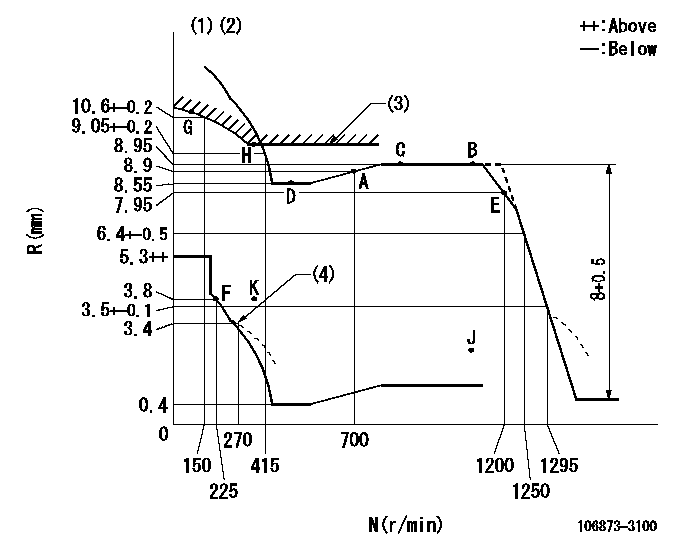

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=10.25+-0.1mm

----------

----------

N1=325r/min R1=3.8mm N2=1100r/min Q1=3mm3/st SXL=10.25+-0.1mm

----------

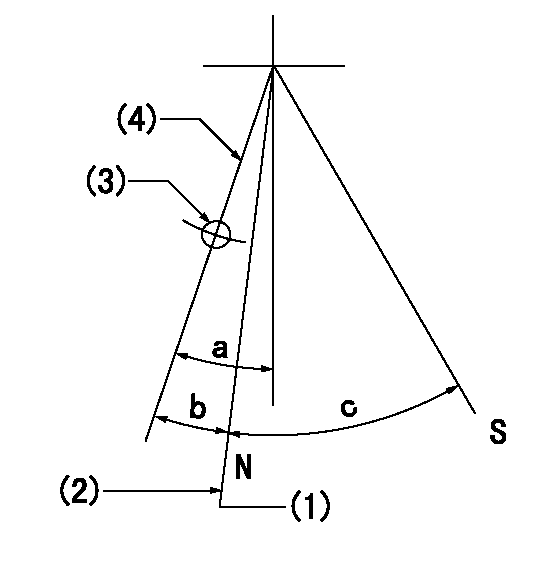

Speed control lever angle

F:Full speed

----------

----------

a=15.5deg+-5deg

----------

----------

a=15.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=39mm

----------

a=39deg+-5deg b=43.5deg+-3deg

----------

aa=39mm

----------

a=39deg+-5deg b=43.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa (at delivery), set before governor adjustment

(2)Set the stopper bolt (apply red paint).

(3)Use the pin at R = bb

(4)Lever free

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

----------

aa=12+-0.1mm bb=37mm

----------

a=(9deg)+-5deg b=9deg+-5deg c=35deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Commercial Oils

If oils other than Caterpillar oils are used, the following oil specifications provide guidelines for the selection of commercial products.* API specifications CF-4, CF-4/SF, or CF-4/SG

Failure to follow the commercial oil recommendation for API CF-4 performance oils can cause shortened engine life due to piston carbon deposits, liner bore polish and/or abnormally higher increasing oil consumption.API CC and CD oils are unacceptable in this Caterpillar diesel engine.

Lubricant Viscosity Recommendations

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change.The recommendation would be to use the highest viscosity oil possible. Even though the ambient temperature may be low, operating engines can still be subjected to normal oil temperatures because of regulated temperature components. The higher viscosity oils will provide better protection to all components which it contacts during the full operating cycle.The use of API CF-4 multi-viscosity oils is recommended because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly. Air Starting Motor Oiler

A lubricator should be used with the starting system.* Use 10 weight non-detergent engine oil above 0°C (32°F) or* diesel fuel or kerosene at temperatures below 0°C (32°F).Lubricant Total Base Number (TBN)

New engine oil must have a TBN of 10 times (for direct injection engines) the percent fuel sulfur as measured by ASTM (American Society of Testing Materials) D2896 method. Refer to the Fuel Specifications in this manual for additional information. Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis or the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The fuel sulfur neutralization of today's new oil formulations along with direct injection (DI) system engines are more effective. Field results indicate that direct injection combustion (DI) systems and the oils now recommended for these engines will operate at an oil TBN equal to 10 times the fuel sulfur. Therefore, the Caterpillar requirements reflect this value of 10 times instead of the previous 20 times for oil TBN when related to fuel sulfur for Cat DI engines and API CF-4 oils. Used oil analysis should be a part of the overall program to provide the assurance that a particular engine installation with all its parameters (engine, oil, operation, maintenance and fuel) are under control. Consult with your Caterpillar dealer for the latest lubrication recommendations.Synthetic Base Stock Oils (SPC)

The performance characteristics of the oil depends on the base oil and

If oils other than Caterpillar oils are used, the following oil specifications provide guidelines for the selection of commercial products.* API specifications CF-4, CF-4/SF, or CF-4/SG

Failure to follow the commercial oil recommendation for API CF-4 performance oils can cause shortened engine life due to piston carbon deposits, liner bore polish and/or abnormally higher increasing oil consumption.API CC and CD oils are unacceptable in this Caterpillar diesel engine.

Lubricant Viscosity Recommendations

The proper SAE grade of oil to select is determined by the minimum outside temperature at which the engine will be started and the maximum outside temperature in which the engine will be operating. This recommendation is to ensure the correct viscosity is used until the next oil change.The recommendation would be to use the highest viscosity oil possible. Even though the ambient temperature may be low, operating engines can still be subjected to normal oil temperatures because of regulated temperature components. The higher viscosity oils will provide better protection to all components which it contacts during the full operating cycle.The use of API CF-4 multi-viscosity oils is recommended because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly. Air Starting Motor Oiler

A lubricator should be used with the starting system.* Use 10 weight non-detergent engine oil above 0°C (32°F) or* diesel fuel or kerosene at temperatures below 0°C (32°F).Lubricant Total Base Number (TBN)

New engine oil must have a TBN of 10 times (for direct injection engines) the percent fuel sulfur as measured by ASTM (American Society of Testing Materials) D2896 method. Refer to the Fuel Specifications in this manual for additional information. Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis or the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The fuel sulfur neutralization of today's new oil formulations along with direct injection (DI) system engines are more effective. Field results indicate that direct injection combustion (DI) systems and the oils now recommended for these engines will operate at an oil TBN equal to 10 times the fuel sulfur. Therefore, the Caterpillar requirements reflect this value of 10 times instead of the previous 20 times for oil TBN when related to fuel sulfur for Cat DI engines and API CF-4 oils. Used oil analysis should be a part of the overall program to provide the assurance that a particular engine installation with all its parameters (engine, oil, operation, maintenance and fuel) are under control. Consult with your Caterpillar dealer for the latest lubrication recommendations.Synthetic Base Stock Oils (SPC)

The performance characteristics of the oil depends on the base oil and