Information injection-pump assembly

BOSCH

9 400 618 392

9400618392

ZEXEL

106873-2840

1068732840

MITSUBISHI

ME093024

me093024

Rating:

Service parts 106873-2840 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME091308

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106873-2840

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 392

9400618392

ZEXEL

106873-2840

1068732840

MITSUBISHI

ME093024

me093024

Zexel num

Bosch num

Firm num

Name

106873-2840

9 400 618 392

ME093024 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9T2 * K 14CD INJECTION PUMP ASSY PE8P PE

8DC9T2 * K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

148.1

143.7

152.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.1+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

15.8

13.4

18.2

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

148.1

147.1

149.1

Basic

*

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(11.4)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

156

152

160

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_05

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

115

75

155

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

650

650

650

Rack position

R2(R1-1.

4)

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

650

650

650

Rack position

R1-0.8

Boost pressure

kPa

8

6.7

9.3

Boost pressure

mmHg

60

50

70

Boost compensator adjustment_03

Pump speed

r/min

650

650

650

Rack position

R1(11.4)

Boost pressure

kPa

14.7

8

21.4

Boost pressure

mmHg

110

60

160

Timer adjustment

Pump speed

r/min

900--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

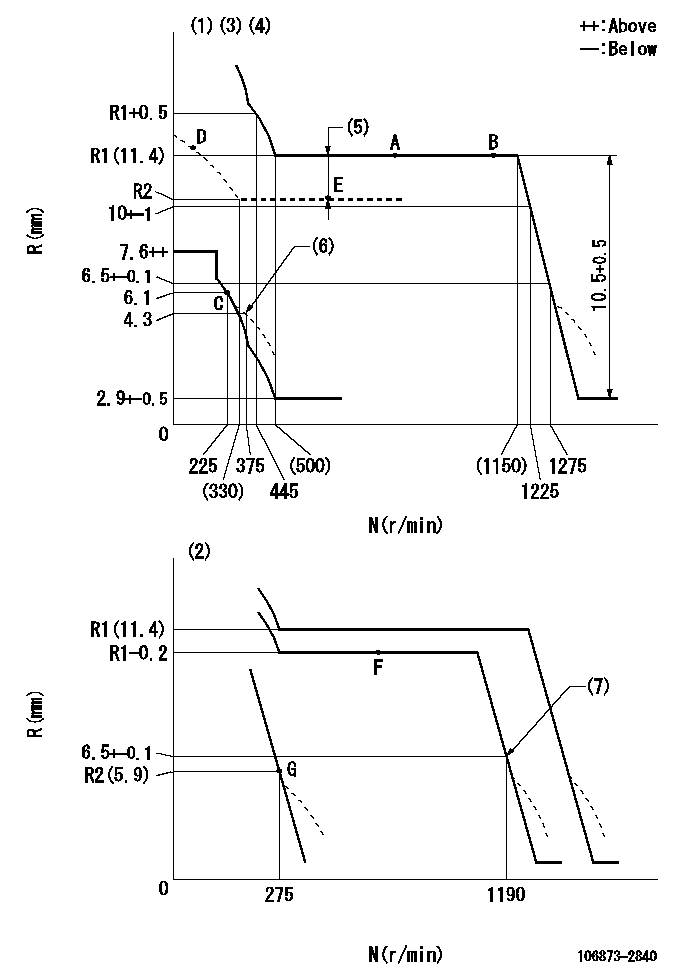

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Adjust with the load control lever in the full position (variable speed specification).

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator cancel stroke: BSL

(5)Boost compensator stroke: BCL

(6)Damper spring setting

(7)When air cylinder is operating.

----------

BSL=1.6mm BCL=1.4+-0.1mm

----------

----------

BSL=1.6mm BCL=1.4+-0.1mm

----------

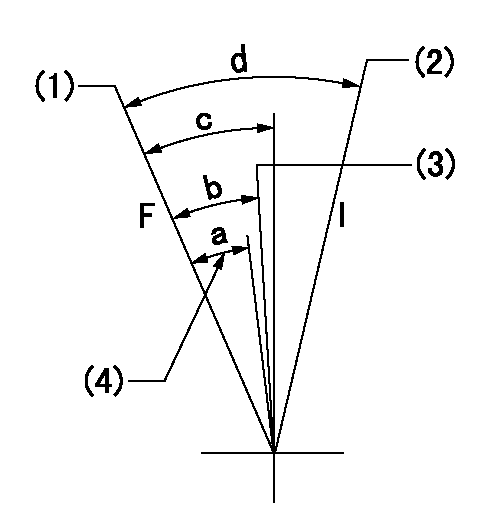

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Pump speed = bb

(3)Pump speed cc

(4)Air cylinder's adjustable range

----------

aa=1275r/min bb=275r/min cc=1190r/min

----------

a=(2deg) b=(2deg)+-5deg c=(7deg)+-5deg d=(16.5deg)+-5deg

----------

aa=1275r/min bb=275r/min cc=1190r/min

----------

a=(2deg) b=(2deg)+-5deg c=(7deg)+-5deg d=(16.5deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=31.5deg+-3deg

----------

----------

a=10deg+-5deg b=31.5deg+-3deg

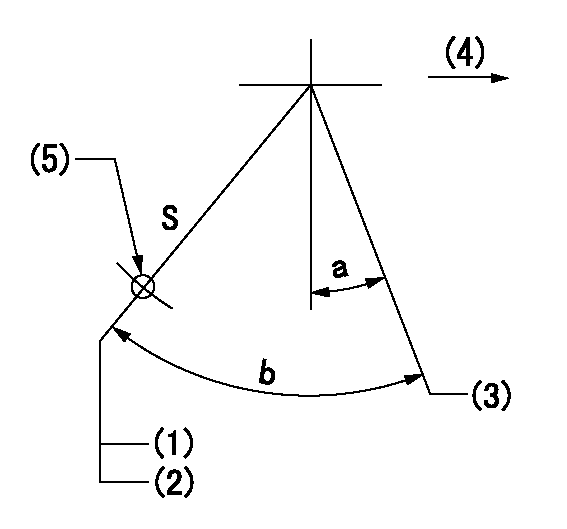

Stop lever angle

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Free (at delivery)

(4)Drive side

(5)Use the hole at R = bb

----------

aa=3.3-0.5mm bb=32mm

----------

a=10.5deg+-5deg b=58deg+7deg-5deg

----------

aa=3.3-0.5mm bb=32mm

----------

a=10.5deg+-5deg b=58deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.6+-0.1mm

----------

----------

N1=325r/min Ra=5.6+-0.1mm

----------

0000001601 2-STAGE CHANGEOVER DEVICE

RFD governor 2 stage changeover mechanism adjustment outline

(A) Bolt

(B) bolt

(c) Nut

(D) Return spring

(E) Bolt

(F) Bolt

(G) Screw

(H) Bolt

(I) Load lever

(J) Speed lever

(K) Air cylinder

(M Air inlet

Figure 1 is only for reference. Lever shape, etc, may vary.

1. Minimum-maximum speed specification adjustment (when running)

(a) Without applying air to the air cylinder, loosen bolts (A) and (B).

(1)High speed return L setting

(a) In the speed range Nf~Nf - 300r/min, adjust using the speed adjusting bolt to determine the temporary beginning of high speed control speed.

(b) Determine the rack position in the vicinity of Rf using the full load lever.

(c) Increase speed and confirm return distance L.

(d) Adjust using the tension lever bolt to obtain L.

(2)Setting full load rack position Rf

(a) Move the load control lever to the full side.

(b) Adjust the full load adjusting bolt so that Rf can be obtained, then fix.

(3)Setting the beginning of high speed operation Nf

(a) Adjust using bolt (E) so that Nf can be obtained, and then fix.

(4)Idle control setting (Re, Ni, Rc)

(a) Set the speed at Ns + 200r/min and move the load control lever to the idle side.

(b) Fix the lever in the position where Re can be obtained.

(c) Next, decrease speed to Ni and screw in the idle spring.

(d) Adjust to obtain rack position Ri.

(e) Increase the speed and after confirming that the rack position is Re at Ns, set the speed at 0.

(f) Confirm protrusion position Rc at idle.

(5)Damper spring adjustment

(a) Increase speed and set the speed at the rack position Rd - 0.1 mm

(b) Set using the damper spring so that the rack position Rd can be obtained.

(c) When Rd is not specified, Rd = Ri - 0.5 mm.

(6)High speed droop confirmation

(a) Return the load control lever to the full load lever position.

(b) Increase the speed and confirm that Rf can be obtained at Nf r/min.

(c) Confirm that speed is Nh at rack position Rh.

2. Variable speed specification adjustment (at operation)

(a) Remove return spring (D).

(b) Apply air pressure of 245~294 kPa {2.5~3 kg/cm2} to the air cylinder.

(c) Perform the following adjustment in this condition.

(1)Setting full load rack position Rf'

(a) Pull the load lever to the idle side.

(b) Obtain rack position Rf' using the nut (C). (Pump speed is Nf'-50 r/min.)

(2)Setting full speed Nf'

(a) Adjust using bolt (B) so that Nf can be obtained, and then fix.

(3)Low speed side setting

(a) At 350r/min, set bolt (F) at beginning of governor operation position, then fix.

3. Bolt (A) adjustment

(1)Install return spring (D) and perform the adjustments below at air pressure 0.

(a) Set at speed Nf using bolt (E).

(b) Screw in bolt (A).

(c) Screw in 1 more turn from the speed lever contact position

(d) Fix bolt (A).

(e) At this time confirm that the air cylinder's shaft moves approximately 1 mm towards the governor.

4. Lever operation confirmation using the air cylinder

(1)Apply 588 kPa {6 kg/cm2} air pressure to the air cylinder.

(2)Confirm that the cylinder piston is moved 50 mm by the spring (D).

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Your engine may not have the same or all of the gauges described. The illustrations shown are of typical gauges. Refer to the OEM Owner Manual for information on the layout of your gauge package. Gauges provide a "look" inside the engine. Be sure they are in good working order. Determine what is the "normal" operating range by observing your gauges over a period of time.Noticeable changes in gauge readings are an indicator of potential gauge or engine problems. This also applies to gauge readings that have changed significantly but are still within specifications. The cause of any sudden or significant change in the readings should be determined and corrected. Contact your Caterpillar dealer for assistance as needed.

Tachometer - Indicates engine rpm. When the throttle control lever is moved to the full speed position without load, the engine is running at high idle. When the throttle control lever is at the full speed position with maximum rated load, the engine is running at the full load rpm (assuming the engine and load are matched).The engine can be operated at high idle without damage, but should never be allowed to exceed high idle rpm with little or no load. The high idle rpm, and the full load rpm, are stamped on the engine's 9L6531 Information Plate.

Service Hour Meter - Indicates the total number of clock hours the engine has operated.

Engine Oil Pressure - Indicates engine oil pressure. The pressure reading will be greatest after starting a cold engine. Oil pressure will decrease as the engine warms while idling. As the engine speed is increased to full load speed, oil pressure will increase and stabilize. Normal oil pressure should read 240 to 480 kPa (35 to 70 psi) when the engine is running between 600 and 2100 rpm with SAE 10W30 oil, at operating oil temperature of 105°C (220°F).* 100 to 200 kPa (15 to 30 psi) below 600 rpmIf the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Check and maintain oil level.

Engine Jacket Water Temperature - Indicates engine coolant water temperature. The gauge should normally indicate between 70 and 90°C (170 and 195°F). The water temperature reading may vary according to load, but should never exceed the boiling temperature for the pressurized system being used. Maximum allowable temperature is 99°C (210°F).

Never add coolant to an overheated engine; allow to cool first. Engine damage and/or personal injury may occur.

The jacket water inlet temperature is regulated with thermostats in the system. Always operate the engine with thermostats installed. Refer to the Cooling System-Thermostats topic in the Maintenance Section of this manual.Somewhat higher temperatures than described above may occur under certain conditions. Maximum allowable operating temperature is 105°C (220°F) with the cooling system pressurized. If the engine is operating above normal range and steam becomes apparent:1. Reduce the load and engine rpm.2. Inspect for cooling system for leaks.3. Determine if the engine must be shutdown immediately or if the engine can

Tachometer - Indicates engine rpm. When the throttle control lever is moved to the full speed position without load, the engine is running at high idle. When the throttle control lever is at the full speed position with maximum rated load, the engine is running at the full load rpm (assuming the engine and load are matched).The engine can be operated at high idle without damage, but should never be allowed to exceed high idle rpm with little or no load. The high idle rpm, and the full load rpm, are stamped on the engine's 9L6531 Information Plate.

Service Hour Meter - Indicates the total number of clock hours the engine has operated.

Engine Oil Pressure - Indicates engine oil pressure. The pressure reading will be greatest after starting a cold engine. Oil pressure will decrease as the engine warms while idling. As the engine speed is increased to full load speed, oil pressure will increase and stabilize. Normal oil pressure should read 240 to 480 kPa (35 to 70 psi) when the engine is running between 600 and 2100 rpm with SAE 10W30 oil, at operating oil temperature of 105°C (220°F).* 100 to 200 kPa (15 to 30 psi) below 600 rpmIf the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Check and maintain oil level.

Engine Jacket Water Temperature - Indicates engine coolant water temperature. The gauge should normally indicate between 70 and 90°C (170 and 195°F). The water temperature reading may vary according to load, but should never exceed the boiling temperature for the pressurized system being used. Maximum allowable temperature is 99°C (210°F).

Never add coolant to an overheated engine; allow to cool first. Engine damage and/or personal injury may occur.

The jacket water inlet temperature is regulated with thermostats in the system. Always operate the engine with thermostats installed. Refer to the Cooling System-Thermostats topic in the Maintenance Section of this manual.Somewhat higher temperatures than described above may occur under certain conditions. Maximum allowable operating temperature is 105°C (220°F) with the cooling system pressurized. If the engine is operating above normal range and steam becomes apparent:1. Reduce the load and engine rpm.2. Inspect for cooling system for leaks.3. Determine if the engine must be shutdown immediately or if the engine can

Have questions with 106873-2840?

Group cross 106873-2840 ZEXEL

Mitsubishi

Mitsubishi

106873-2840

9 400 618 392

ME093024

INJECTION-PUMP ASSEMBLY

8DC9T2

8DC9T2