Information injection-pump assembly

BOSCH

9 400 618 273

9400618273

ZEXEL

106871-8450

1068718450

HINO

220006630A

220006630a

Rating:

Service parts 106871-8450 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2230A

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/24.5{250}

15.

NOZZLE SET

Include in #1:

106871-8450

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 273

9400618273

ZEXEL

106871-8450

1068718450

HINO

220006630A

220006630a

Zexel num

Bosch num

Firm num

Name

106871-8450

9 400 618 273

220006630A HINO

INJECTION-PUMP ASSEMBLY

F17C K

F17C K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

140.2

138.2

142.2

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

136.8

130.8

142.8

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

9.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

138.4

135.4

141.4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

9.8

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

143.8

140.8

146.8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

9.4

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

119.3

116.3

122.3

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

4.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9.1

6.1

12.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

900

Advance angle

deg.

1.7

1.4

2

Load

3/4

Timer adjustment_02

Pump speed

r/min

1060

Advance angle

deg.

4.75

4.45

5.05

Load

4/4

Remarks

Finish

Finish

Test data Ex:

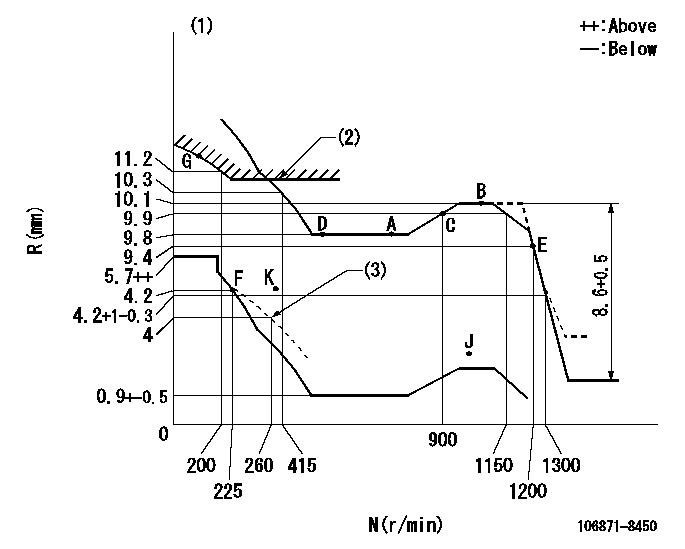

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Excess fuel setting for starting: SXL (N = N1)

(3)Set the damper spring (after setting the idle spring).

----------

SXL=11+-0.1mm N1=300r/min

----------

----------

SXL=11+-0.1mm N1=300r/min

----------

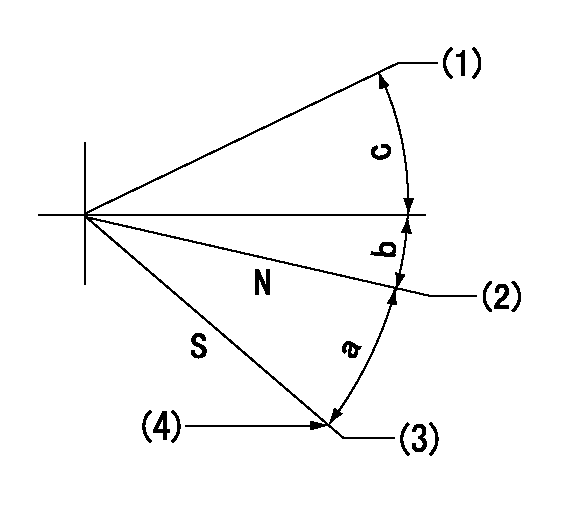

Speed control lever angle

F:Full speed

----------

----------

a=14deg+-5deg

----------

----------

a=14deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=42mm

----------

a=39deg+-5deg b=46deg+-3deg

----------

aa=42mm

----------

a=39deg+-5deg b=46deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at shipping)

(2)Rack position = aa

(3)Rack position bb

(4)Set the stopper bolt (apply red paint).

----------

aa=12mm bb=3mm

----------

a=26deg+-5deg b=5deg+-5deg c=(28deg)

----------

aa=12mm bb=3mm

----------

a=26deg+-5deg b=5deg+-5deg c=(28deg)

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1070r/min Ra=10.1mm

----------

----------

N1=1070r/min Ra=10.1mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Lubrication For A Rebuilt Engine

It is very important for a rebuilt engine to have "adequate" (needed) lubrication during the first seconds of operation. A "dry start" (without needed lubrication) on a rebuilt engine can cause bearing damage.When an engine is rebuilt with new parts, oil is put on each part as it is installed. This is generally enough lubrication for engine start-up. However, this lubrication may not be enough or may be lost if the rebuilt engine is placed in storage for any length of time.When a factory assembled short block assembly is installed, the oil used at the factory has to give this needed lubrication. However, the factory oil application can flow off the parts in a short block during storage or shipment. As a result, the parts in a rebuilt engine will not have "adequate" lubrication at start-up.To prevent the possibility of a "dry start" and bearing damage during the first seconds of running, use the 1P540 Flow Checking Tool Group, and shop air pressure to pressure lubricate (fill the main oil passage with oil under pressure) all rebuilt engines.Procedure for Pressure Lubrication

1. Clean the tank of the 1P540 Flow Checking Tool Group thoroughly, and set the pressure regulator to 35 5 psi (240 35 kPa).

Air pressure should not be more than 50 psi (345 kPa) at any time.

2. Put approximately one gallon of engine oil in the tank.

PRESSURE LUBRICATION (Using the 1P540 Flow Checking Tool Group)3. Connect the tooling to the engine as shown. The tap shown is connected to the main oil passage.4. Add air pressure to the tank, with the regulator set at 35 5 psi (240 35 kPa). Although the tank does have a hand pump, it is difficult to get enough air pressure to do the job with the hand pump. Therefore, use of shop air is recommended.5. Let the one gallon of engine oil flow into the oil passage under pressure.When filling the crankcase, put in one gallon of oil less than the recommendation in the Lubrication and Maintenance Guides, if engine has received this pressure lubrication application. Also, if the engine is not going to be used for a long time, do the above procedure again before the first starting.If shop air is not available for charging the tank, the hand pump may be used to get the minimum required pressure.

Do not use the same 1P540 Flow Checking Tool Group for both "pressure lubrication application" and for checking fuel flow. Incorrect cleaning is probable if the tool is used for both fuel and lube oil. Even a minute amount of dirt in the fuel system can cause fuel nozzle failure.

Dynamometer Test Precaution

To avoid possible engine damage while testing on a dynamometer, the thermostats must be installed and the shunt line connected as shown.

SHUNT LINE CONNECTED TO ENGINEInitial Operation After Engine Reconditioning

The quality of oil control components used in Caterpillar engines is such that, following engine reconditioning (with Caterpillar Service Parts), only an initial operational check

It is very important for a rebuilt engine to have "adequate" (needed) lubrication during the first seconds of operation. A "dry start" (without needed lubrication) on a rebuilt engine can cause bearing damage.When an engine is rebuilt with new parts, oil is put on each part as it is installed. This is generally enough lubrication for engine start-up. However, this lubrication may not be enough or may be lost if the rebuilt engine is placed in storage for any length of time.When a factory assembled short block assembly is installed, the oil used at the factory has to give this needed lubrication. However, the factory oil application can flow off the parts in a short block during storage or shipment. As a result, the parts in a rebuilt engine will not have "adequate" lubrication at start-up.To prevent the possibility of a "dry start" and bearing damage during the first seconds of running, use the 1P540 Flow Checking Tool Group, and shop air pressure to pressure lubricate (fill the main oil passage with oil under pressure) all rebuilt engines.Procedure for Pressure Lubrication

1. Clean the tank of the 1P540 Flow Checking Tool Group thoroughly, and set the pressure regulator to 35 5 psi (240 35 kPa).

Air pressure should not be more than 50 psi (345 kPa) at any time.

2. Put approximately one gallon of engine oil in the tank.

PRESSURE LUBRICATION (Using the 1P540 Flow Checking Tool Group)3. Connect the tooling to the engine as shown. The tap shown is connected to the main oil passage.4. Add air pressure to the tank, with the regulator set at 35 5 psi (240 35 kPa). Although the tank does have a hand pump, it is difficult to get enough air pressure to do the job with the hand pump. Therefore, use of shop air is recommended.5. Let the one gallon of engine oil flow into the oil passage under pressure.When filling the crankcase, put in one gallon of oil less than the recommendation in the Lubrication and Maintenance Guides, if engine has received this pressure lubrication application. Also, if the engine is not going to be used for a long time, do the above procedure again before the first starting.If shop air is not available for charging the tank, the hand pump may be used to get the minimum required pressure.

Do not use the same 1P540 Flow Checking Tool Group for both "pressure lubrication application" and for checking fuel flow. Incorrect cleaning is probable if the tool is used for both fuel and lube oil. Even a minute amount of dirt in the fuel system can cause fuel nozzle failure.

Dynamometer Test Precaution

To avoid possible engine damage while testing on a dynamometer, the thermostats must be installed and the shunt line connected as shown.

SHUNT LINE CONNECTED TO ENGINEInitial Operation After Engine Reconditioning

The quality of oil control components used in Caterpillar engines is such that, following engine reconditioning (with Caterpillar Service Parts), only an initial operational check

Have questions with 106871-8450?

Group cross 106871-8450 ZEXEL

Hino

106871-8450

9 400 618 273

220006630A

INJECTION-PUMP ASSEMBLY

F17C

F17C