Information injection-pump assembly

BOSCH

9 400 612 052

9400612052

ZEXEL

106871-8310

1068718310

HINO

220203400A

220203400a

Rating:

Service parts 106871-8310 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-2110A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106871-8310

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 052

9400612052

ZEXEL

106871-8310

1068718310

HINO

220203400A

220203400a

Zexel num

Bosch num

Firm num

Name

106871-8310

9 400 612 052

220203400A HINO

INJECTION-PUMP ASSEMBLY

EF750T K 14CD INJECTION PUMP ASSY PE8P PE

EF750T K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

145.3

143.3

147.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

171.4

165.4

177.4

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.6+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

18.4

15.4

21.4

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

172

172

192

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

880--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

830

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

Test data Ex:

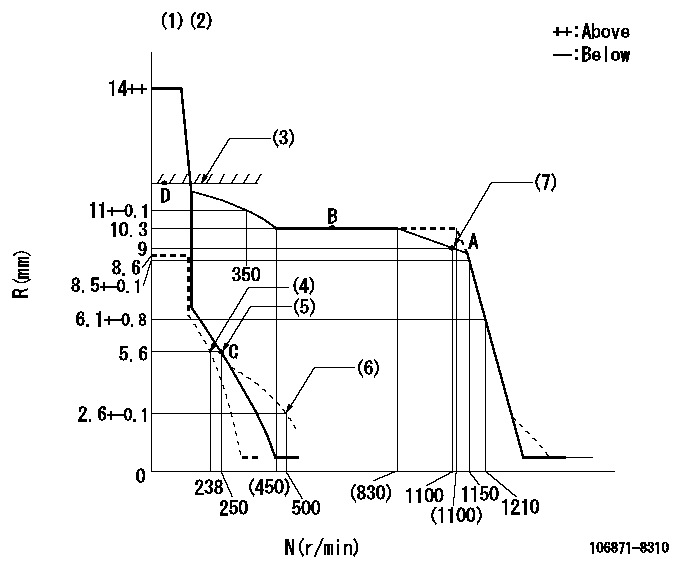

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Damper spring setting

(7)Set the torque spring.

----------

K=11

----------

----------

K=11

----------

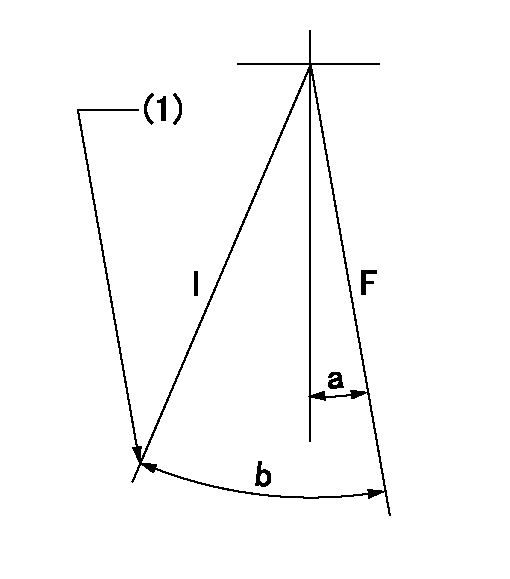

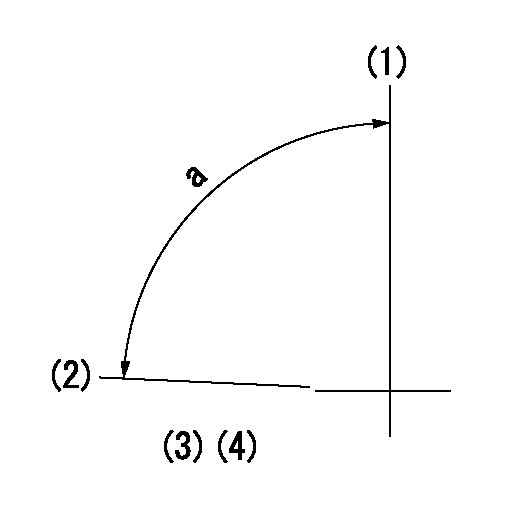

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9deg+-5deg b=23deg+-5deg

----------

----------

a=9deg+-5deg b=23deg+-5deg

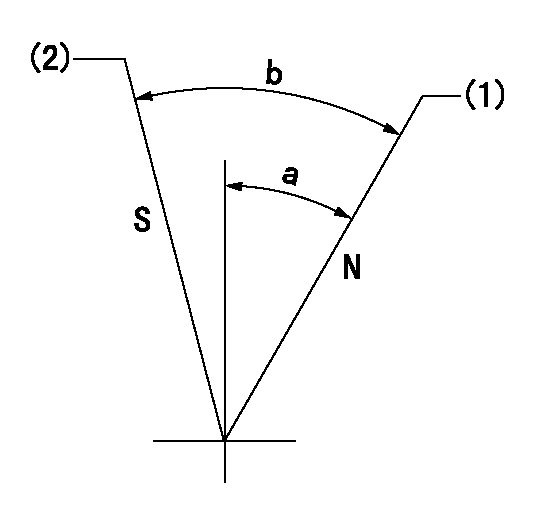

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Speed = aa, rack position = bb or less (idle rack - cc)

----------

aa=0r/min bb=5.1mm cc=0.5mm

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

aa=0r/min bb=5.1mm cc=0.5mm

----------

a=26.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(85deg)

----------

----------

a=(85deg)

Information:

WRENCH INSTALLED

1. 8S2243 Wrench. 2. Protective cap. 3. Retaining bushing.c. Install extractor (4).d. Remove retaining bushing (3) and wrench (1).e. Remove the seal and lift fuel injection pump (5) out of the housing. Keep components together and identified as to location.4. Remove rack (7) and rack bumper spring (6).

REMOVING PUMP

4. 8S2244 Extractor. 5. Fuel injection pump.

REMOVING RACK

6. Rack bumper spring. 7. Rack.5. Use magnet (8) to remove lifters (9). Identify lifters (9) and keep them with their respective fuel injection pumps.

REMOVING LIFTERS

8. 8S2293 Magnet. 9. Lifter.6. Remove the camshaft gear assembly retaining bolt (11) and lock. Remove plate assembly (10).

REMOVING PLATE ASSEMBLY

10. Plate assembly. 11. Bolt.7. Remove camshaft gear assembly (12) from camshaft (13).

REMOVING GEAR ASSEMBLY

12. Gear assembly. 13. Camshaft.

REMOVING BOLTS

14. Lock. 15. Bolts.8. Remove bolts (15) and lock (14).9. Remove camshaft retaining plate (16).

REMOVING RETAINING PLATE

16. Retaining plate.10. Remove camshaft (13).

REMOVING CAMSHAFT

13. Camshaft.11. Use camshaft bearing removal and installation group (17) to remove the camshaft bearings from the fuel injection pump housing.

REMOVING BEARINGS

17. 8S2241 Camshaft Bearing Removal and Installation Group.Assemble Fuel Injection Pump Housing

1. Use camshaft bearing removal and installation group (17) to install the camshaft bearings in the fuel injection pump housing. The camshaft bearings must be installed with the oil holes in the bearings in line with the oil hole in the housing. The front and rear bearings must be line bored after installation. To align oil holes and line bore the bearings, See Special Instruction (GMG00672).

INSTALLING BEARINGS

17. 8S2241 Camshaft Bearing Removal and Installation Group.2. Put clean engine oil (SAE 30) on the camshaft and install camshaft (13) in the fuel injection pump housing.

INSTALLING CAMSHAFT

13. Camshaft.3. Install the camshaft retaining plate (16).4. Install lock (14) and bolts (15).

INSTALLING RETAINING PLATE

16. Retaining plate.

INSTALLING BOLTS

14. Lock. 15. Bolts.5. Install camshaft gear assembly (12) on camshaft (13).

INSTALLING GEAR ASSEMBLY

12. Gear assembly. 13. Camshaft.6. Install plate assembly (10), retaining bolt (11), and lock.

INSTALLING PLATE ASSEMBLY

10. Plate assembly. 11. Bolt. Be sure to put the spacer on bolt (11).7. Use magnet (8) to install lifters (9). The lifters (9) must be installed in the same location from which they were removed.

INSTALLING LIFTERS

8. 8S2293 Magnet. 9. Lifters.8. Lubricate the rack with clean fuel oil. Install rack (7) with timing pin slot in rack toward front of the housing. Install rack bumper spring (6) so the large diameter of the bumper spring will be against the housing. If new lifters and pumps are to be installed it will be necessary to check and/or adjust the fuel pump timing dimension. See FUEL PUMP TIMING DIMENSION SETTING-OFF ENGINE in TESTING AND ADJUSTING section of the Service Manual.

INSTALLING RACK

6. Rack bumper spring. 7. Rack.9. Remove bolts (19) and rack cover (18).

RACK COVER

18. Rack cover. 19. Bolts.

TIMING PIN INSTALLED

20. Slot in rack. 21. 8S2291 or FT887 Timing Pin.10. The rack must be centered to install the fuel injection pumps. To center the rack, pull the rack toward the governor end of the housing until centering slot (20) in the rack is under the centering pin hole.

Have questions with 106871-8310?

Group cross 106871-8310 ZEXEL

Hino

106871-8310

9 400 612 052

220203400A

INJECTION-PUMP ASSEMBLY

EF750T

EF750T