Information injection-pump assembly

BOSCH

9 400 618 184

9400618184

ZEXEL

106871-5680

1068715680

NISSAN-DIESEL

1680197661

1680197661

Rating:

Cross reference number

BOSCH

9 400 618 184

9400618184

ZEXEL

106871-5680

1068715680

NISSAN-DIESEL

1680197661

1680197661

Zexel num

Bosch num

Firm num

Name

106871-5680

9 400 618 184

1680197661 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RG8 K

RG8 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

4.7

4.67

4.73

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-5 deg. 135 134.75 135.25

Cal 1-5 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-3 deg. 225 224.75 225.25

Cal 1-3 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-6 deg. 270 269.75 270.25

Cal 1-6 deg. 270 269.75 270.25

Difference between angles 7

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Rack position

(13.4)

Vist

V

1.85

1.85

1.85

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

137

135

139

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(8.4)

Vist

V

2.6

2.5

2.7

Pump speed

r/min

335

335

335

Average injection quantity

mm3/st.

14

12

16

Max. variation between cylinders

%

0

-10

10

Governor adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Q = 155+-2 (mm3/st) / N = 650 (r/min), beginning of effect

Q = 155+-2 (mm3/st) / N = 650 (r/min), beginning of effect

Governor adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.3

Remarks

Q=155+-2(mm3/st)/N=650 (r/min)

Q=155+-2(mm3/st)/N=650 (r/min)

Governor adjustment_03

Pump speed

r/min

(750)

Advance angle

deg.

2.3

2

2.6

Remarks

Q=155+-2(mm3/st)/N=650 (r/min)

Q=155+-2(mm3/st)/N=650 (r/min)

Governor adjustment_04

Pump speed

r/min

825

Advance angle

deg.

2.3

2

2.6

Remarks

Q=87+-2(mm3/st)/N=850(r/min)

Q=87+-2(mm3/st)/N=850(r/min)

Governor adjustment_05

Pump speed

r/min

1080

Advance angle

deg.

7.3

7

7.6

Remarks

Q = 146+-2 (mm3/st) / N = 1100 (r/min), end of effect

Q = 146+-2 (mm3/st) / N = 1100 (r/min), end of effect

Test data Ex:

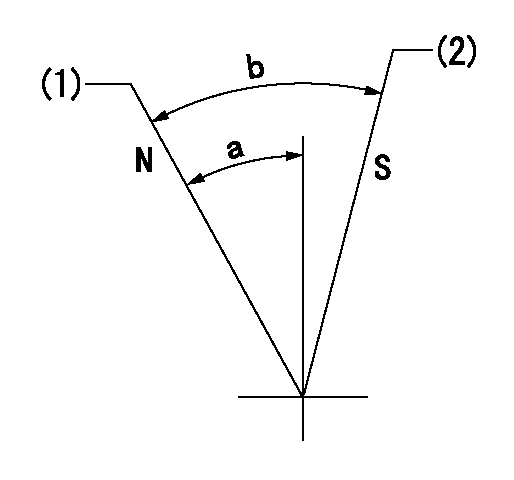

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

0000000901

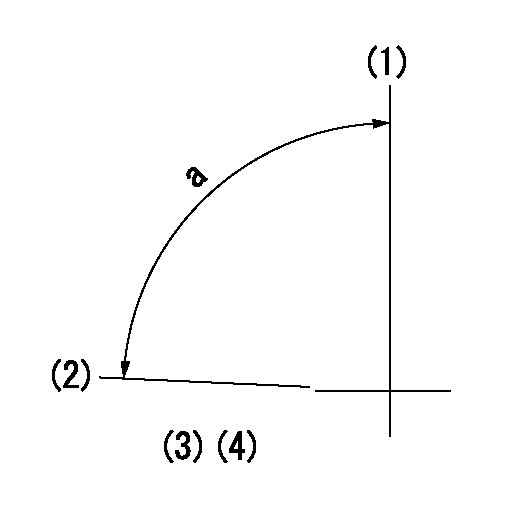

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Stop lever angle

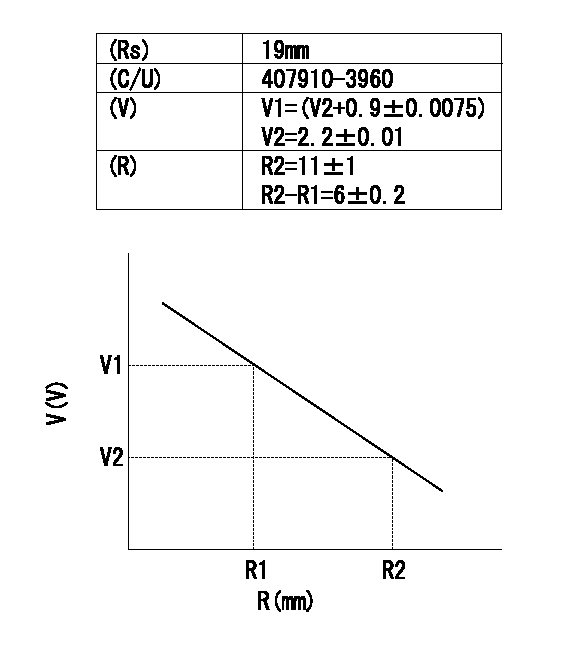

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

(1) Bore in connecting rod for piston pin bearing ... 55.436 0.013 mm (2.1825 .0005 in.)Tight fit between connecting rod eye and piston pin bearing ... 0.05 to 0.10 mm (.002 to .004 in.) Connecting rod must be heated for installation of piston pin bearing. Do not use a torch.Heat connecting rod for piston pin bearing installation to a temperature of ... 177 to 260° C (350 to 500° F)Position of pin bearing:

Positioning Pin Bearing (Type A)Type A (Narrow Taper) - Bearing junction and locating hole are 180° apart (directly across from each other). Bearing junction and locating hole must be assembled within either area "A" (90 10° from centerline through the connecting rod bores) as shown.

Positioning Pin Bearing (Type B)Type B (Wide Taper) - Bearing junction and locating hole are 155° apart (not directly across from each other). Bearing junction and locating holes must be assembled in the top half of connecting rod eye area "A" (12.5 1° above the horizontal centerline) as shown.Make reference to Special Instruction Form No. SMHS7295 for use of pin bearing removal and installation tools and procedures.(2) Bore in connecting rod for bearing with nuts tight to specifications (6) ... 103.500 0.013 mm (4.0748 .0005 in.)(3) Distance between center of bearings ... 261.62 0.05 mm (10.300 .002 in.)(4) Bore in bearing for piston pin (new) ... 50.830 0.008 mm (2.0012 .0003 in.)Diameter of piston pin (new) ... 50.795 0.005 mm (1.9998 .0002 in.)Maximum permissible clearance between bearing and piston pin (worn) ... 0.08 mm (.003 in.)(5) Bore in bearing for crankshaft ... 97.119 to 97.175 mm (3.8236 to 3.8258 in.)Clearance between bearing and crankshaft (new) ... 0.071 to 0.168 mm (.0028 to .0066 in.)Maximum permissible clearance between bearing and crankshaft (worn) ... 0.25 mm (.010 in.) Bearings are available in 0.63 mm (.025 in.) and 1.27 mm (.050 in.) smaller than original size.

Marks For Tightening Connecting Rod Bolts(6) Tightening procedure for connecting rod bolts:a. Put 2P2506 Thread Lubricant on bolt threads and contact surfaces of nut and cap.b. Tighten both nuts to ... 80 8 N m (60 6 lb.ft.)c. Put a mark on each nut and end of bolt as shown.d. Tighten each nut from mark ... 120 5° The connecting rod must be installed so the chamfer on the edge of bore (5) is near the corner on the crankshaft. The side opposite the chamfered edge must be against the other connecting rod on the same crankshaft pin.Side clearance between two connecting rods on the same crankshaft pin (new) ... 0.28 to 0.84 mm (.011 to .033 in.)Make reference to Special Instruction Form Nos. GMG02394 & SMHS7366 for information to check and recondition connecting rods. Also see, Guideline For Reusable Parts; Salvage Of Non-Serrated Connecting Rods, Form No. SEBF8064.

Positioning Pin Bearing (Type A)Type A (Narrow Taper) - Bearing junction and locating hole are 180° apart (directly across from each other). Bearing junction and locating hole must be assembled within either area "A" (90 10° from centerline through the connecting rod bores) as shown.

Positioning Pin Bearing (Type B)Type B (Wide Taper) - Bearing junction and locating hole are 155° apart (not directly across from each other). Bearing junction and locating holes must be assembled in the top half of connecting rod eye area "A" (12.5 1° above the horizontal centerline) as shown.Make reference to Special Instruction Form No. SMHS7295 for use of pin bearing removal and installation tools and procedures.(2) Bore in connecting rod for bearing with nuts tight to specifications (6) ... 103.500 0.013 mm (4.0748 .0005 in.)(3) Distance between center of bearings ... 261.62 0.05 mm (10.300 .002 in.)(4) Bore in bearing for piston pin (new) ... 50.830 0.008 mm (2.0012 .0003 in.)Diameter of piston pin (new) ... 50.795 0.005 mm (1.9998 .0002 in.)Maximum permissible clearance between bearing and piston pin (worn) ... 0.08 mm (.003 in.)(5) Bore in bearing for crankshaft ... 97.119 to 97.175 mm (3.8236 to 3.8258 in.)Clearance between bearing and crankshaft (new) ... 0.071 to 0.168 mm (.0028 to .0066 in.)Maximum permissible clearance between bearing and crankshaft (worn) ... 0.25 mm (.010 in.) Bearings are available in 0.63 mm (.025 in.) and 1.27 mm (.050 in.) smaller than original size.

Marks For Tightening Connecting Rod Bolts(6) Tightening procedure for connecting rod bolts:a. Put 2P2506 Thread Lubricant on bolt threads and contact surfaces of nut and cap.b. Tighten both nuts to ... 80 8 N m (60 6 lb.ft.)c. Put a mark on each nut and end of bolt as shown.d. Tighten each nut from mark ... 120 5° The connecting rod must be installed so the chamfer on the edge of bore (5) is near the corner on the crankshaft. The side opposite the chamfered edge must be against the other connecting rod on the same crankshaft pin.Side clearance between two connecting rods on the same crankshaft pin (new) ... 0.28 to 0.84 mm (.011 to .033 in.)Make reference to Special Instruction Form Nos. GMG02394 & SMHS7366 for information to check and recondition connecting rods. Also see, Guideline For Reusable Parts; Salvage Of Non-Serrated Connecting Rods, Form No. SEBF8064.

Have questions with 106871-5680?

Group cross 106871-5680 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106871-5680

9 400 618 184

1680197661

INJECTION-PUMP ASSEMBLY

RG8

RG8