Information injection-pump assembly

BOSCH

9 400 611 546

9400611546

ZEXEL

106871-5670

1068715670

NISSAN-DIESEL

1671397875

1671397875

Rating:

Service parts 106871-5670 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97079

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

14.

NOZZLE

Include in #1:

106871-5670

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 611 546

9400611546

ZEXEL

106871-5670

1068715670

NISSAN-DIESEL

1671397875

1671397875

Zexel num

Bosch num

Firm num

Name

106871-5670

9 400 611 546

1671397875 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RF8TD K 14CD INJECTION PUMP ASSY PE8P PE

RF8TD K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

211

209

213

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

235

235

235

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

12.1+-0.

1

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

150

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R1(8.8)

Boost pressure

kPa

5.3

5.3

5.3

Boost pressure

mmHg

40

40

40

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

11.2

Boost pressure

kPa

12

10.7

13.3

Boost pressure

mmHg

90

80

100

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

12.1+-0.

1

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

770--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

720

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

930

Advance angle

deg.

3

2.7

3.3

Remarks

Finish

Finish

Test data Ex:

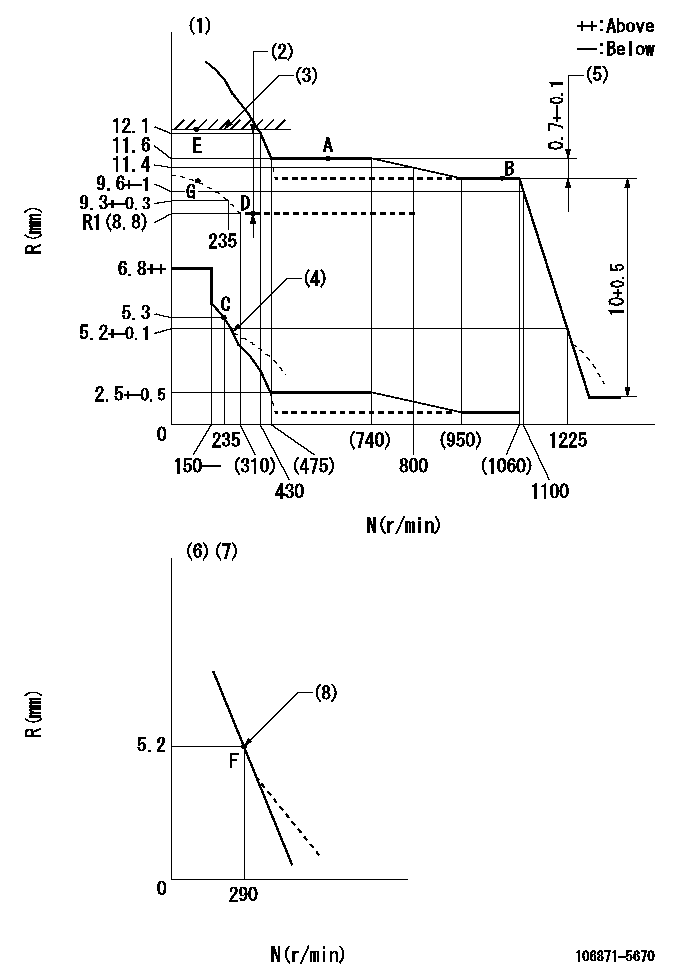

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator stroke: BCL

(3)Rack limit using stop lever: RA

(4)Damper spring setting: DL

(5)Rack difference between N = N1 and N = N2

(6)Variable speed specification: idling adjustment

(7)Fix the lever at the full-load position at delivery.

(8)Main spring setting

----------

BCL=(3.3)mm RA=12.1+-0.1mm DL=4.8-0.2mm N1=1000r/min N2=600r/min

----------

----------

BCL=(3.3)mm RA=12.1+-0.1mm DL=4.8-0.2mm N1=1000r/min N2=600r/min

----------

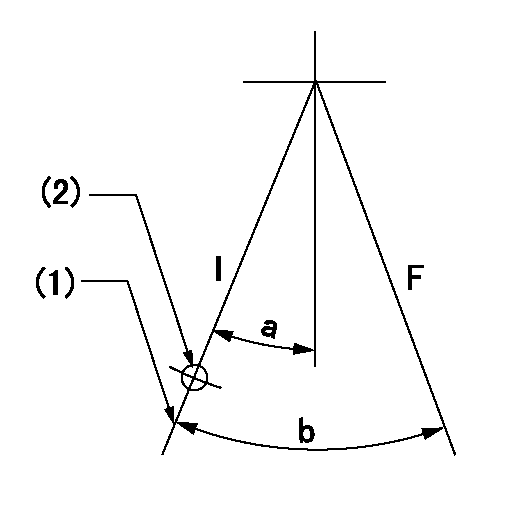

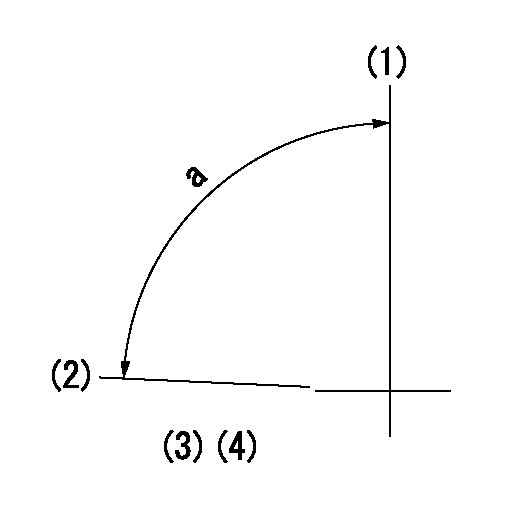

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Set the stopper bolt (fixed at full-load position at delivery.)

----------

aa=290r/min

----------

a=14deg+-5deg b=4deg+-5deg

----------

aa=290r/min

----------

a=14deg+-5deg b=4deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=33.5deg+-3deg

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=33.5deg+-3deg

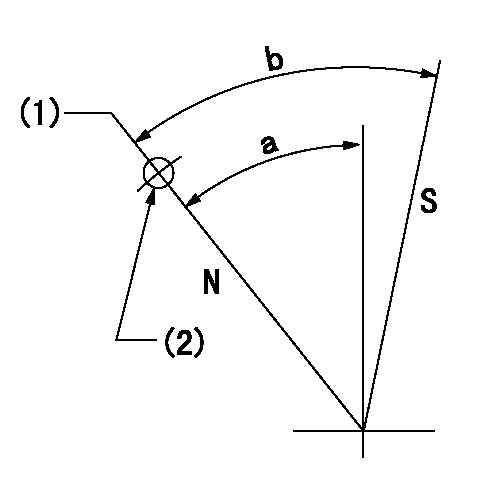

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the pin at R = bb

----------

aa=12.1+-0.1mm bb=46mm

----------

a=36.5deg+-5deg b=38.5deg+-5deg

----------

aa=12.1+-0.1mm bb=46mm

----------

a=36.5deg+-5deg b=38.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

(1) Torque for three studs to hold the water pump ... 27 4 N m (20 3 lb.ft.)(2) Plug (two on front and two on rear). Put 5P3413 Pipe Sealant on the threads of the plugs.(3) Length of dowels (four) out of the block face ... 18.5 0.5 mm (.73 .02 in.)(4) Thickness of the gasket between the cylinder block and top plates ... 0.21 0.03 mm (.008 .001 in.)(5) Thickness of the top plates ... 8.59 0.03 mm (.338 .001 in.)(6) Make reference to Cylinder Liner Projection, for the height of the liner.(7) Bore in the block for the camshaft bearings (seven bores) ... 76.835 0.018 mm (3.0250 .0007 in.)(8) Torque for one plug on front and two on rear of the block ... 80 14 N m (60 10 lb.ft.)Put 5P3413 Pipe Sealant on the threads of the plug.(9) Bore in the block for the main bearings (with main bearing caps torqued):Standard, original size (new) ... 129.891 0.013 mm (5.1138 .0005 in.)0.64 mm (.025 in.) larger than original size ... 130.526 0.013 mm (5.1388 .0005 in.)(10) Projection of dowels (four) out of the front and rear faces of the block ... 19.0 0.5 mm (.75 .02 in.)(11) Width of slot for bearing cap ... 215.900 0.013 mm (8.5000 .0005 in.)Width of bearing cap ... 215.900 0.013 mm (8.5000 .0005 in.)Clearance between slot and bearing cap (with main bearing caps torqued) 0.025 mm (.0010 in.) tight to 0.025 mm (.0010 in.) loose(12) Torque for the bolts that hold the piston cooling tubes ... 24 7 N m (18 5 lb.ft.)(13) Torque for the bolts that hold the caps for the main bearings:Install the main bearing caps with the marks (arrow) toward the front of the engine. Each cap has a number on the bottom and must be installed in the same position as the correct number on the left side of the block pan rail.a. Put 2P2506 Thread Lubricant on the threads of the bolts.b. Tighten the bolts on left (tab) side to ... 260 14 N m (190 10 lb.ft.)c. Tighten the bolts on right side to ... 260 14 N m (190 10 lb.ft.)d. Put a mark on each bolt and cap.e. Tighten the bolts on right side, from the mark ... 120°f. Tighten the bolts on left side, from the mark ... 120° (14) Dimension (new) from the centerline of crankshaft bearing bore to top of block (top deck) ... 419.10 0.15 mm (16.00 .006 in.)(15) Dimension (new) from centerline of crankshaft bearing bore to bottom of block (pan rails) ... 165.10 0.10 mm (6.500 .004 in.)

Right Side Of Engine(16) Plug. Two plugs - one located at front and the other located at rear of right cylinder bank.(17) Plug. Use 6V1541 Quick Cure Primer and 9S3265 Retaining Compound in the plug bores

Right Side Of Engine(16) Plug. Two plugs - one located at front and the other located at rear of right cylinder bank.(17) Plug. Use 6V1541 Quick Cure Primer and 9S3265 Retaining Compound in the plug bores

Have questions with 106871-5670?

Group cross 106871-5670 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106871-5670

9 400 611 546

1671397875

INJECTION-PUMP ASSEMBLY

RF8TD

RF8TD