Information injection-pump assembly

BOSCH

F 01G 09U 0AE

f01g09u0ae

ZEXEL

106871-5662

1068715662

Rating:

Cross reference number

BOSCH

F 01G 09U 0AE

f01g09u0ae

ZEXEL

106871-5662

1068715662

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.9

3.87

3.93

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-5 deg. 135 134.75 135.25

Cal 1-5 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-3 deg. 225 224.75 225.25

Cal 1-3 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-6 deg. 270 269.75 270.25

Cal 1-6 deg. 270 269.75 270.25

Difference between angles 7

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Rack position

(13.7)

Vist

V

1.8

1.8

1.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

141.5

139.5

143.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(9)

Vist

V

2.5

2.4

2.6

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

16

14

18

Max. variation between cylinders

%

0

-10

10

Test data Ex:

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(9)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(9)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

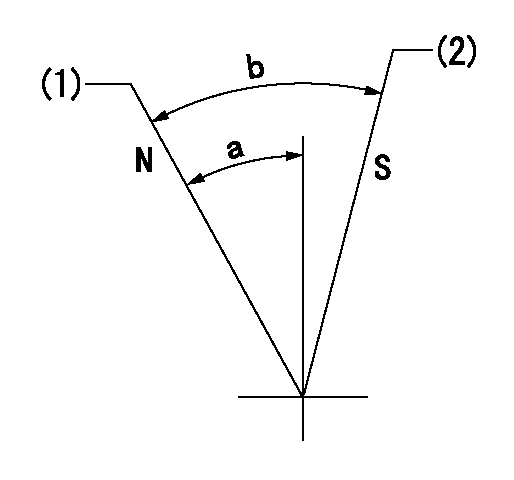

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

0000000901

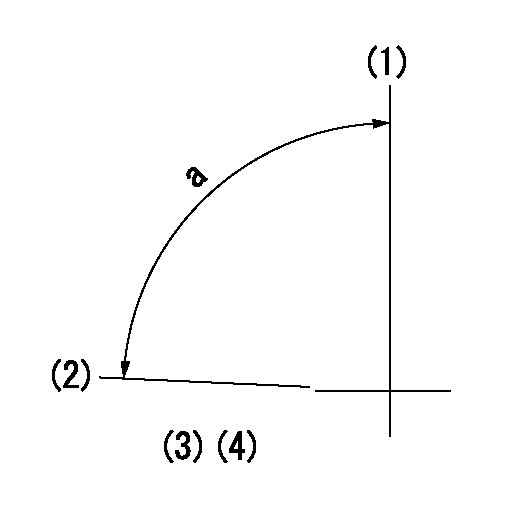

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Stop lever angle

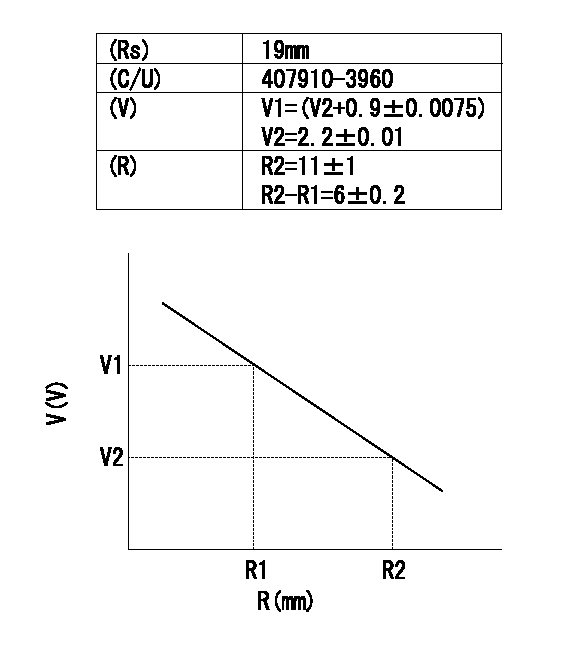

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

(1) End play for shaft (new) ... 0.114 0.038 mm (.0045 .0015 in.) Maximum permissible end play (worn) ... 0.20 mm (.008 in.)(2) Tighten band clamps with procedure that follows: a. Tighten to ... 13.6 1.1 N (120 10 lb.in.)b. Tap (hit) clamp lightly all around.c. Tighten again to ... 13.6 1.1 N (120 10 lb.in.)(3) Thickness of thrust bearing ... 5.36 0.03 mm (.211 .001 in.)(4) Diameter of shaft (new) ... 14.254 to 14.262 mm (.5612 to .5615 in.) Bore in the bearing (new) ... 14.293 to 14.300 mm (.5627 to .5630 in.)Maximum permissible clearance between bearing and shaft (worn) ... 0.08 mm (.003 in.)(5) Maximum permissible gap of oil seal ring, measured in bore of housing ... 0.23 mm (.009 in.)(6) Bore in housing (new) ... 22.255 to 22.268 mm (.8762 to .8767 in.) Outside diameter of the bearing (new) ... 22.144 to 22.154 mm (.8718 to .8722 in.)Maximum permissible clearance between bearing and bore in housing (worn) ... 0.15 mm (.006 in.)(7) Turbocharger impeller installation at room temperature: a. Put 6V1541 Quick Cure Primer on the nut and the shaft threads to clean them, if necessary.b. Put a small amount of 9S3265 Retaining Compound on the nut and shaft threads.

Do not let the retaining compound get into the compressor wheel bore or on the shaft, because it can make removal of the compressor wheel difficult during future turbocharger disassembly.

c. Put a small amount of lubricant, such as Lubriplate, on the nut seat area on the compressor. Do not put lubricant on the threads.d. Tighten the compressor wheel retainer nut to a torque of ... 60 3 N m (44 2 lb.ft.)

Do not bend or add stress to the shaft when the nut is tightened.

(8) Thickness of each thrust ring ... 2.553 0.013 mm (.1005 .0005 in.)(9) Torque for four nuts (put 5P3931 Anti-Seize Compound on threads) ... 55 5 N m (40 4 lb.ft.)

Do not let the retaining compound get into the compressor wheel bore or on the shaft, because it can make removal of the compressor wheel difficult during future turbocharger disassembly.

c. Put a small amount of lubricant, such as Lubriplate, on the nut seat area on the compressor. Do not put lubricant on the threads.d. Tighten the compressor wheel retainer nut to a torque of ... 60 3 N m (44 2 lb.ft.)

Do not bend or add stress to the shaft when the nut is tightened.

(8) Thickness of each thrust ring ... 2.553 0.013 mm (.1005 .0005 in.)(9) Torque for four nuts (put 5P3931 Anti-Seize Compound on threads) ... 55 5 N m (40 4 lb.ft.)