Information injection-pump assembly

ZEXEL

106871-5652

1068715652

NISSAN-DIESEL

1680197611

1680197611

Rating:

Service parts 106871-5652 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97163

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

14.

NOZZLE

Include in #1:

106871-5652

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-5652

1068715652

NISSAN-DIESEL

1680197611

1680197611

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.9

3.87

3.93

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-5 deg. 135 134.75 135.25

Cal 1-5 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-3 deg. 225 224.75 225.25

Cal 1-3 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-6 deg. 270 269.75 270.25

Cal 1-6 deg. 270 269.75 270.25

Difference between angles 7

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Rack position

(13.7)

Vist

V

1.8

1.8

1.8

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

141.5

139.5

143.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(9)

Vist

V

2.5

2.4

2.6

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

16

14

18

Max. variation between cylinders

%

0

-10

10

Test data Ex:

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(9deg) t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(9deg) t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

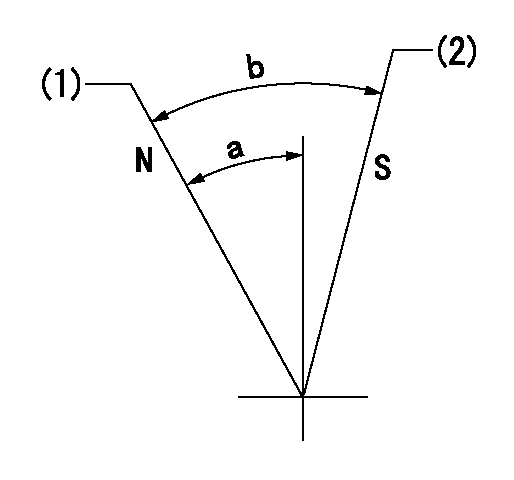

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

0000000901

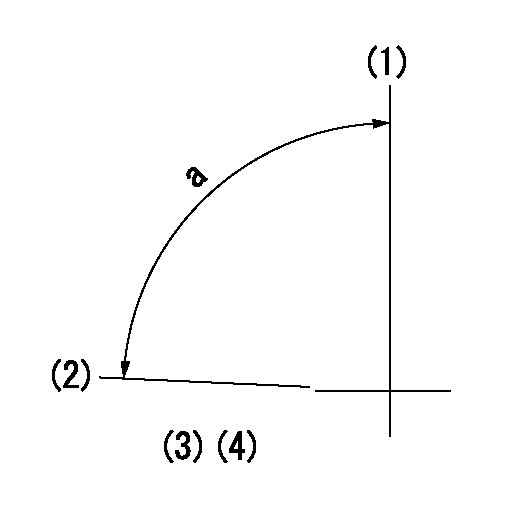

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Stop lever angle

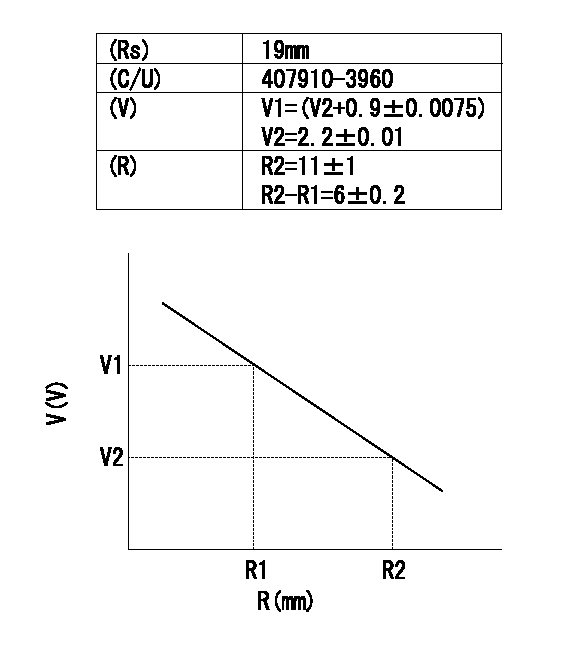

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

(1) Torque for fuel injection line nut ... 40 7 N m (30 5 lb.ft.)(2) Torque for retainer ... 48 7 N m (35 5 lb.ft.)(3) Torque for bleed screw ... 2.2 0.8 N m (20 7 lb.in.) Always use a new washer (seal) anytime the bleed screw is loosened or removed.(4) Washer. Make sure the correct washer is used when the nozzle assembly is installed.(5) Put liquid soap on rubber O-ring and bore in head before assembly.(6) Put 5P3931 Anti-Seize Compound on the threads of the adapter before installation. Torque for the adapter ... 205 14 N m (150 10 lb.ft.)See Testing And Adjusting section, for fuel injection nozzle test procedure.Earlier Engines

(1) Nut for fuel line. Hold adapter assembly (2) when nut (1) is loosened or tightened. Torque for the nut ... 40 7 N m (30 5 lb.ft.)(2) Adapter assembly.(3) Torque for bleed screw ... 1.6 0.4 N m (14 4 lb.in.)Always use a new washer (seal) anytime the bleed screw is loosened or removed.(4) Washer. Make sure the correct washer is used when the nozzle assembly is installed. Check the Engine Arrangement for the correct part number to use.(5) Torque for clamp bolt ... 31 7 N m (23 5 lb.ft.)(6) Put liquid soap on rubber O-ring and bore in head before assembly.(7) Put 5P3931 Anti-Seize Compound on the threads of the adapter before installation. Torque for the adapter ... 205 14 N m (150 10 lb.ft.)Engines With Capsule-Type Nozzles

Earlier Engines

(1) Torque for

(1) Nut for fuel line. Hold adapter assembly (2) when nut (1) is loosened or tightened. Torque for the nut ... 40 7 N m (30 5 lb.ft.)(2) Adapter assembly.(3) Torque for bleed screw ... 1.6 0.4 N m (14 4 lb.in.)Always use a new washer (seal) anytime the bleed screw is loosened or removed.(4) Washer. Make sure the correct washer is used when the nozzle assembly is installed. Check the Engine Arrangement for the correct part number to use.(5) Torque for clamp bolt ... 31 7 N m (23 5 lb.ft.)(6) Put liquid soap on rubber O-ring and bore in head before assembly.(7) Put 5P3931 Anti-Seize Compound on the threads of the adapter before installation. Torque for the adapter ... 205 14 N m (150 10 lb.ft.)Engines With Capsule-Type Nozzles

Earlier Engines

(1) Torque for