Information injection-pump assembly

BOSCH

9 400 611 911

9400611911

ZEXEL

106871-5630

1068715630

NISSAN-DIESEL

1671397874

1671397874

Rating:

Service parts 106871-5630 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97162

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106871-5630

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 611 911

9400611911

ZEXEL

106871-5630

1068715630

NISSAN-DIESEL

1671397874

1671397874

Zexel num

Bosch num

Firm num

Name

106871-5630

9 400 611 911

1671397874 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RG8 K

RG8 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

126

125

127

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Solenoid boost comp. OFF

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.65

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

138

136

140

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Solenoid boost comp. OFF

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

14

12

16

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Solenoid boost comp. OFF

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

R1(10.4)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

109.5

107.5

111.5

Fixing the lever

*

Solenoid boost comp. ON

*

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

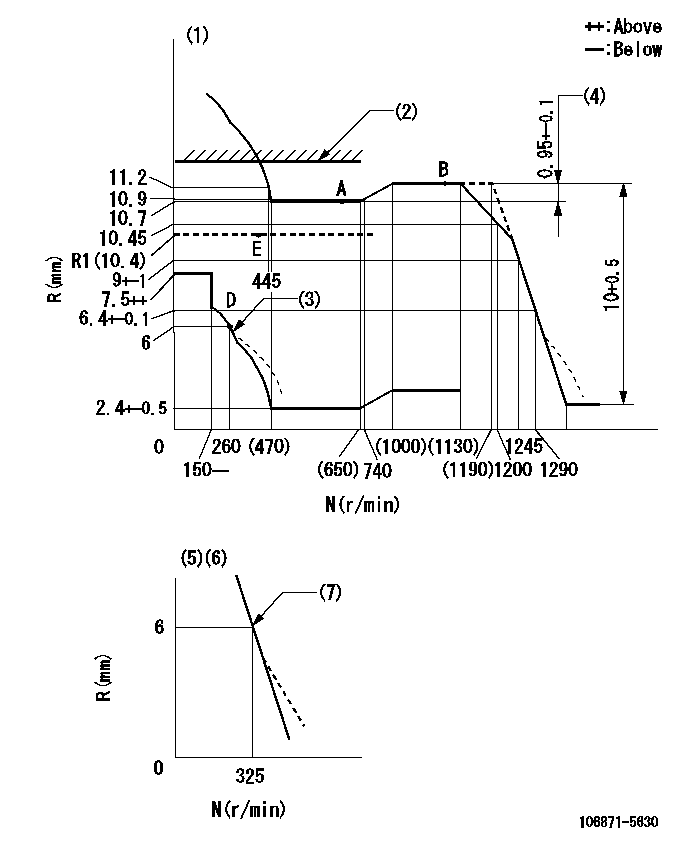

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Rack limit using the stop lever: SRL

(3)Damper spring setting: DL

(4)Rack difference between N = N1 and N = N2

(5)Variable speed specification: idling adjustment

(6)Fix the lever at the full-load position at delivery.

(7)Main spring setting

----------

SRL=12.4+-0.1mm DL=5.5-0.2mm N1=1100r/min N2=600r/min

----------

----------

SRL=12.4+-0.1mm DL=5.5-0.2mm N1=1100r/min N2=600r/min

----------

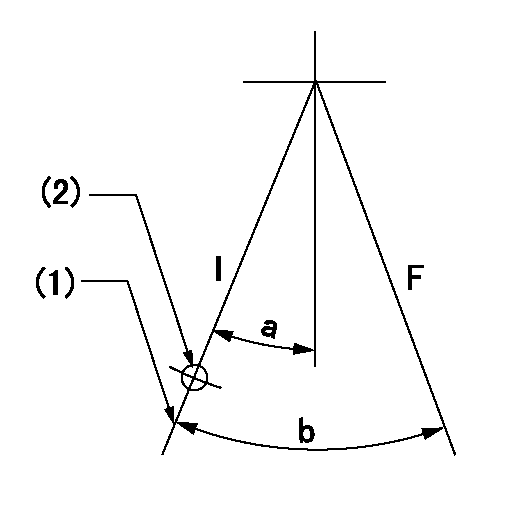

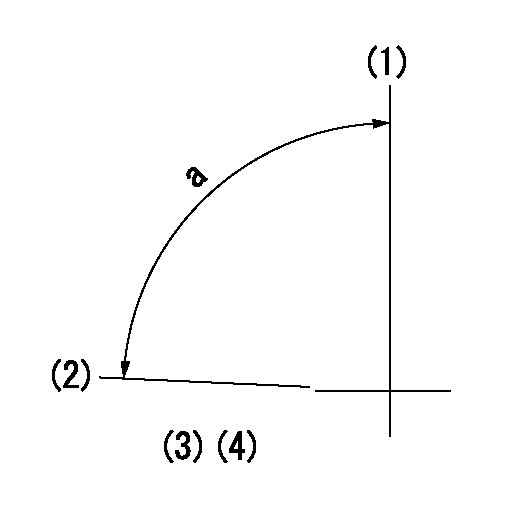

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Set the stopper bolt (fixed at full-load position at delivery.)

----------

aa=325r/min

----------

a=16deg+-5deg b=12deg+-5deg

----------

aa=325r/min

----------

a=16deg+-5deg b=12deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=30.5deg+-3deg

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=30.5deg+-3deg

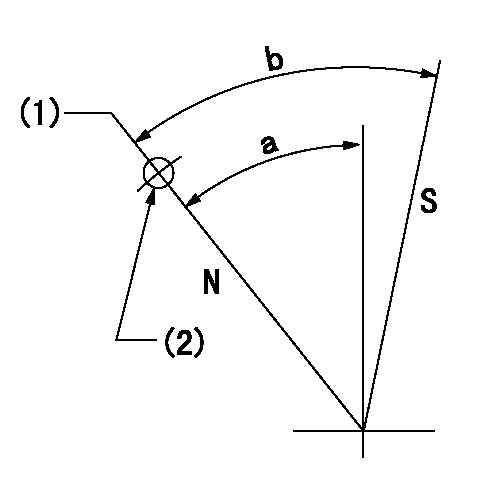

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the pin at R = bb

----------

aa=12.4+-0.1mm bb=46mm

----------

a=36deg+-5deg b=38deg+-5deg

----------

aa=12.4+-0.1mm bb=46mm

----------

a=36deg+-5deg b=38deg+-5deg

0000001501 BCS

(A) Screw for precise adjustment

(B) Pre-adjustment screw

(C) Control rack, rack decrease direction

(D) Rack limit

1. Solenoid boost compensator adjustment

(1)Supply DC: V1 to the solenoid terminals and confirm solenoid operation.

(2)With the solenoid ON, calculate L1 from the value of R1. [L1 = La - (10.5 - R1) +-0.2]

(3)Adjust (B) to obtain L1.

(4)Assemble the solenoid to the governor.

(5)With the solenoid ON, readjust (B) so that R1 is within the allowance a.

(6)With the solenoid OFF, perform all governor adjustments except rack limit adjustment.

(7)Set the pump speed at N1 and turn the solenoid ON.

(8)Adjust (A) so that R1 is within the allowance range a.

(9)Set the pump speed at N1 and fix the load lever in the full position

(10)Turn the solenoid switch ON and OFF several times and confirm that the difference in rack positions is within L2.

(11)Set the rack limit.

(12)Stamp the solenoid valve.

----------

V1=24V N1=400r/min N2=0r/min R1=10.4mm a=+-0.5mm La=31mm L1=(30.9)+-0.2mm L2=3.5~5mm

----------

----------

V1=24V N1=400r/min N2=0r/min R1=10.4mm a=+-0.5mm La=31mm L1=(30.9)+-0.2mm L2=3.5~5mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

August 31, 2004

O-219

Priority PRODUCT IMPROVEMENT PROGRAM FOR REPLACINGTHE INJECTION ACTUATION PRESSURE SENSOR ON CERTAIN 3126E ENGINES

7755,1925 PI30676

This Program must be administered assoon as possible. When reporting the repair, use "PI30676" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30676" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

February 28, 2005 August 31, 2005PROBLEM

Replace the injection actuation pressure sensorcertain 3126E engines. The old sensor may leak oil.AFFECTED PRODUCT

Model IdentificationNumber

3126E G3E230-497PARTS NEEDED

Qty

Part Number Description

1 2244536 SENSOR GP-PRACTION REQUIRED

Remove the 194-6726 Pressure Sensor and replaceit with part number 224-4536 Pressure Sensor.OWNER NOTIFICATION

U.S. and Canadian owners will receive the attachedOwner Notification.SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts LaborHrs Parts LaborHrs

100% 1.0 0 0 0 0

This is a 1.0-hour job. U.S. and Canadian Dealers Only - Eligibledealers may enter a Type 2 SIMS ReportPARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.MAKE EVERY EFFORT TO COMPLETE THIS PROGRAMAS SOON AS POSSIBLE.Attach. (Owner Notification)COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999PRIORITY - THE INJECTION ACTUATION PRESSURESENSOR NEEDS TO BE REPLACED.MODELS INVOLVED - CERTAIN 3126E ENGINESDear Caterpillar Product Owner:A new injection actuation pressure sensor needsto be installed on the products listed below. The current sensor may leakoil. You will not be charged for the service performed.Contact your local Caterpillar dealer immediatelyto schedule this service. The dealer will advise you of the time requiredto complete this service. Please refer the dealer to their Service Letterdated August 31, 2004 when scheduling this service.We regret the inconvenience this may causeyou, but urge you to have this service performed as soon as possible toprevent unscheduled downtime.Caterpillar Inc.

Identification #(s)Attached to August 31, 2004 Service Letter

O-219

Priority PRODUCT IMPROVEMENT PROGRAM FOR REPLACINGTHE INJECTION ACTUATION PRESSURE SENSOR ON CERTAIN 3126E ENGINES

7755,1925 PI30676

This Program must be administered assoon as possible. When reporting the repair, use "PI30676" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30676" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

February 28, 2005 August 31, 2005PROBLEM

Replace the injection actuation pressure sensorcertain 3126E engines. The old sensor may leak oil.AFFECTED PRODUCT

Model IdentificationNumber

3126E G3E230-497PARTS NEEDED

Qty

Part Number Description

1 2244536 SENSOR GP-PRACTION REQUIRED

Remove the 194-6726 Pressure Sensor and replaceit with part number 224-4536 Pressure Sensor.OWNER NOTIFICATION

U.S. and Canadian owners will receive the attachedOwner Notification.SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs Parts LaborHrs Parts LaborHrs

100% 1.0 0 0 0 0

This is a 1.0-hour job. U.S. and Canadian Dealers Only - Eligibledealers may enter a Type 2 SIMS ReportPARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.MAKE EVERY EFFORT TO COMPLETE THIS PROGRAMAS SOON AS POSSIBLE.Attach. (Owner Notification)COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999PRIORITY - THE INJECTION ACTUATION PRESSURESENSOR NEEDS TO BE REPLACED.MODELS INVOLVED - CERTAIN 3126E ENGINESDear Caterpillar Product Owner:A new injection actuation pressure sensor needsto be installed on the products listed below. The current sensor may leakoil. You will not be charged for the service performed.Contact your local Caterpillar dealer immediatelyto schedule this service. The dealer will advise you of the time requiredto complete this service. Please refer the dealer to their Service Letterdated August 31, 2004 when scheduling this service.We regret the inconvenience this may causeyou, but urge you to have this service performed as soon as possible toprevent unscheduled downtime.Caterpillar Inc.

Identification #(s)Attached to August 31, 2004 Service Letter

Have questions with 106871-5630?

Group cross 106871-5630 ZEXEL

Nissan-Diesel

Nissan-Diesel

106871-5630

9 400 611 911

1671397874

INJECTION-PUMP ASSEMBLY

RG8

RG8