Information injection-pump assembly

ZEXEL

106871-4340

1068714340

Rating:

Cross reference number

ZEXEL

106871-4340

1068714340

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

157

157

Overflow valve opening pressure

kgf/cm2

1.6

1.6

1.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side No.1

Governor side No.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

125.5

124.5

126.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.1+-0.5

Pump speed

r/min

280

280

280

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

130

150

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.7

4.3

Remarks

Finish

Finish

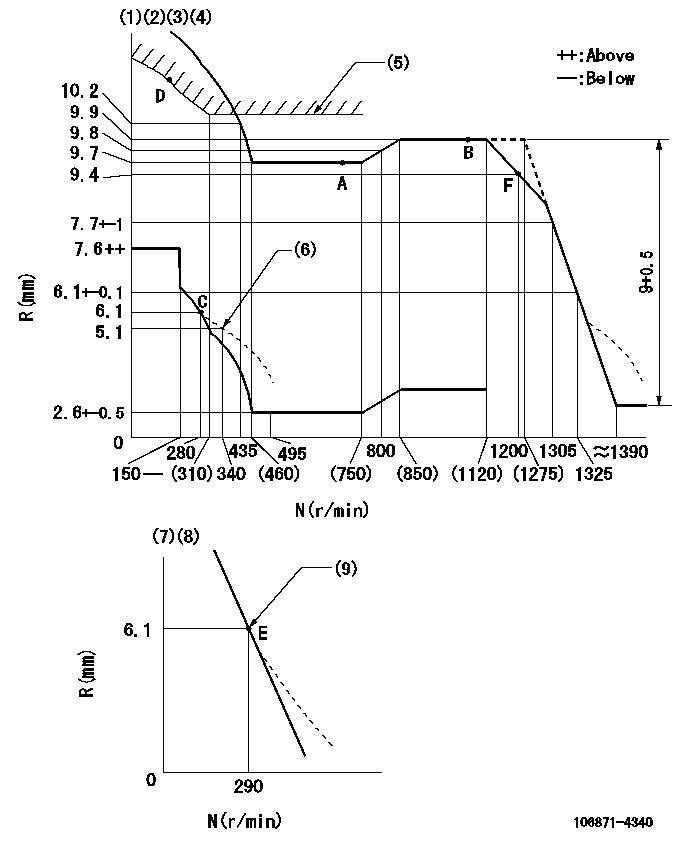

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust governor at speed not exceeding N = N1. Output voltage VR+-0.01 (V), speed N1 r/min, governor Vist = V1 (V)

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Lever ratio: RT

(4)Target shim dimension: TH

(5)Excess fuel setting for starting: SXL (N = N2)

(6)Damper spring setting

(7)Variable speed specification: idling adjustment

(8)Fix the lever at the full-load position at delivery.

(9)Main spring setting

----------

N1=1710r/min RT=1 TH=2.8mm SXL=10.2+-0.1mm N2=400r/min

----------

----------

N1=1710r/min RT=1 TH=2.8mm SXL=10.2+-0.1mm N2=400r/min

----------

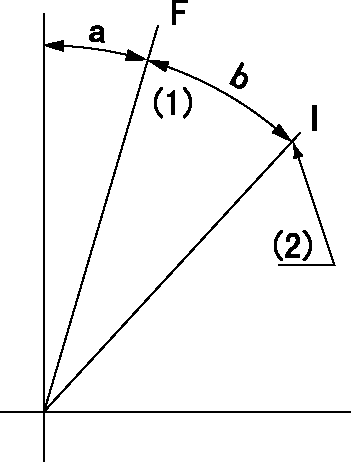

Speed control lever angle

F:Full speed

I:Idle

(1)Set the stopper bolt (fixed at full-load position at delivery.)

(2)Pump speed = aa

----------

aa=290r/min

----------

a=(6deg)+-5deg b=(17deg)+-5deg

----------

aa=290r/min

----------

a=(6deg)+-5deg b=(17deg)+-5deg

0000000901

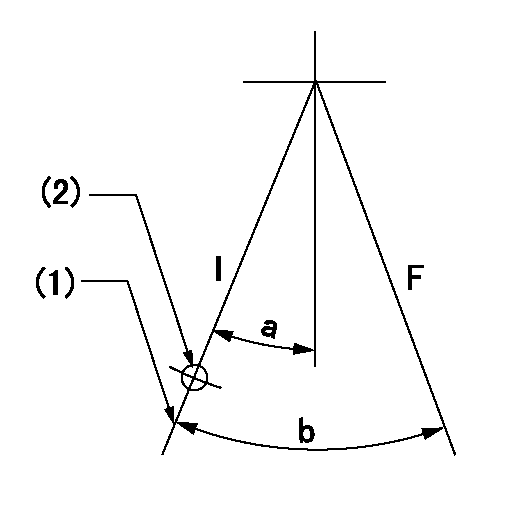

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=26.5deg+-3deg

----------

aa=64.3mm

----------

a=18.5deg+-5deg b=26.5deg+-3deg

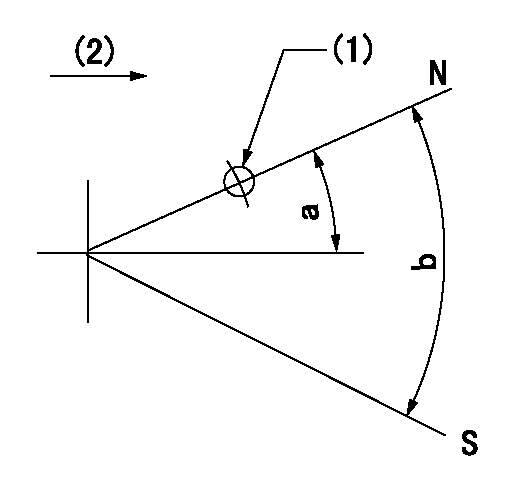

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Drive side

----------

aa=28mm

----------

a=12deg+-5deg b=64deg+-5deg

----------

aa=28mm

----------

a=12deg+-5deg b=64deg+-5deg

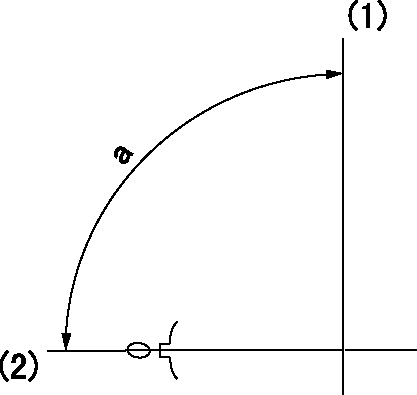

Timing setting

(1)Pump vertical direction

(2)Position of the coupling key groove at the beginning of injection of the No. 8 cylinder.

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

TERMINATION DATE

30Sep2013

PROBLEM

The existing fuel injectors can experience internal body cracks due to material inclusions and variability in the factory tightening procedure and/or the poppet sticking as a result of body and valve tolerancing on certain C32 marine engines. If the existing fuel injector fails it can result in complaints of misfire and/or low power.

AFFECTED PRODUCT

Model Identification Number

C32 RND00276-00339

RNE00126-00140

RNX00104-00110, 112, 115-136, 140, 145, 148-158, 162-165, 169-202, 206, 209-212, 214-217, 219-220, 222, 224-228, 232-238, 240-247, 250, 252-253, 257, 263, 265, 267-282, 284-285, 288-289, 291-305, 307, 310, 312-317, 320, 323, 325-329, 334-339, 341-343

RNY00102-00107, 119-120, 123-129, 135, 137, 154, 156-162, 171, 173, 183, 190-192, 196-200, 202-203, 205, 210-211, 213, 220-222, 225-226, 228-236, 238-242, 244-246, 248-249, 253-258, 260, 263-266, 269, 276, 280, 282, 285-286, 289-300, 302-305, 308-309, 312-315, 317-318, 327, 333-335, 337-349, 352, 356-358, 360-361, 363-366, 368, 370, 386, 391, 398-403, 406-408, 411-414, 417-419, 421-428, 443-448, 452-453, 456-457, 459-471, 474, 476, 478-489, 491-492, 497, 499-500, 502-507, 511-513, 516, 518-519, 521, 529-539, 541-542, 544, 546, 549, 551-554, 556-558, 571, 579-581, 585, 600-602, 606, 609-610, 613, 617-619, 621, 624-642, 644-665, 667, 672, 674, 676-677, 686-687, 695, 697-698, 700-702, 707-709, 711-728, 731-734, 737, 741, 746-748, 751-752, 755, 763, 765, 767, 777-782, 786-787, 794, 796, 798-799, 802, 804-820, 826, 829, 836, 842, 848, 859, 862, 866-867, 872-875, 886, 890-891, 894, 896-903, 909-910, 913-919, 925, 927, 929, 931, 934, 938, 952-954, 959-960, 973

RNZ00101-00158, 160, 162-181, 183-189, 191-220, 222-223, 225-231, 233-250, 252-253, 255-261, 263-270, 272-274, 276-294, 296-304, 306-447, 449-450, 452-456, 459-491, 493-496, 498-499, 502, 512-514

T3T00103-00104, 114, 134, 144-145, 147-150, 154-160, 164-213, 215-381, 383

PARTS NEEDED

Qty

Part Number Description

12 8S9191 BOLT

12 10R7231 FUEL INJECTOR GP

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 7% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Take the following actions only after a failure occurs on one or more injectors in any of the engines listed in the Affected Product. A fuel injector is considered a failure if the following troubleshooting procedure is completed and the problem is not resolved.

1. Update the ECM software.

2. If still unable to produce advertised power, use publication SEBD9408 to determine if a change to FLS/FTS is required.

3. If still unable to produce advertised power, test the injector solenoid per RENR9326.

4. If still unable to produce advertised power, test the unit injector per SENR9773.

5. Replace injector(s) as required.

If one or more injectors fail replace all injectors at the time of repair.

Refer to Disassembly and Assembly, RENR8628 for the removal and installation procedure of the unit injector.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-2000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 10.0-hour job

For multiple engines that are serviced in a single vessel, please reference the other engine serial numbers in the claim story.

For before failure claims, please reference the after failure sister vessel engine serial