Information injection-pump assembly

ZEXEL

106871-3930

1068713930

HINO

220005061A

220005061a

Rating:

Cross reference number

ZEXEL

106871-3930

1068713930

HINO

220005061A

220005061a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

162

160

164

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.7

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

175

169

181

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Injection quantity adjustment_03

Adjusting point

E

Rack position

7.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

127.5

125.5

129.5

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

121

121

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

G

Rack position

4.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.8

5.8

11.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

H

Rack position

-

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

180

177

183

Fixing the lever

*

Boost pressure

kPa

25.3

25.3

Boost pressure

mmHg

190

190

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

7.5

Boost pressure

kPa

4

1.3

6.7

Boost pressure

mmHg

30

10

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

8.1

Boost pressure

kPa

12

12

12

Boost pressure

mmHg

90

90

90

Timer adjustment

Pump speed

r/min

(950)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

2

1.7

2.3

Remarks

Finish

Finish

Test data Ex:

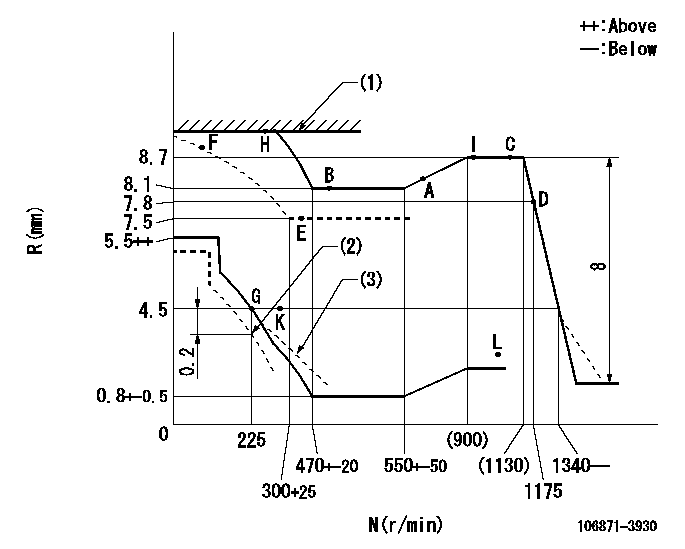

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Set idle at delivery

(3)Damper spring setting: DL

----------

DL=2.9-0.2mm

----------

----------

DL=2.9-0.2mm

----------

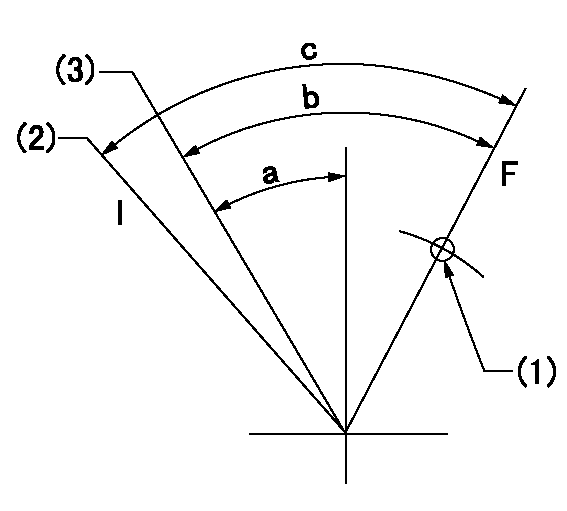

Speed control lever angle

F:Full speed

----------

----------

a=17deg+-5deg

----------

----------

a=17deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)At delivery

(3)Point G setting

----------

aa=46mm

----------

a=20deg+-5deg b=36deg+-3deg c=37deg+-5deg

----------

aa=46mm

----------

a=20deg+-5deg b=36deg+-3deg c=37deg+-5deg

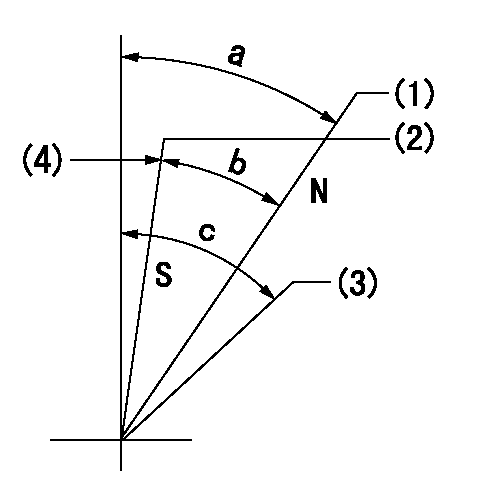

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Free (at delivery)

(4)Stopper bolt setting

----------

aa=11mm bb=2.5-0.5mm

----------

a=24deg+-5deg b=24deg+-5deg c=(40deg)

----------

aa=11mm bb=2.5-0.5mm

----------

a=24deg+-5deg b=24deg+-5deg c=(40deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

These recommendations are subject to change without notice. Consult your local Cat dealer for the most up to date recommendations.

Diesel engines may burn a wide variety of fuels. These fuels are divided into two general groups. The two groups are called the preferred fuels and the permissible fuels.The preferred fuels provide maximum engine service life and performance. The preferred fuels are distillate fuels. These fuels are commonly called diesel fuel, furnace oil, gas oil, or kerosene. These fuels must meet the “Cat Specification for Distillate Diesel Fuel for Off-Highway Diesel Engines” found in this Special Publication, "Distillate Diesel Fuel" article.The permissible fuels are some crude oils, some blends of crude oil with distillate fuel, and some marine diesel fuel. These fuels are not suitable for use in all engine applications. The acceptability of these fuels for use is determined on a case by case basis. A complete fuel analysis is required. Consult your Cat dealer for further information. Biodiesel fuel is permissible for use in Cat engines. Follow all the recommendations and guidelines given in this Special Publication, "Biodiesel" article.Note: Except for some biodiesel, permissible fuels are not acceptable for use in on-highway applications.

Use of permissible fuels can result in higher maintenance costs and reduced engine service life.

Note: Use of fuels that do not meet at least the minimum performance recommendations and/or requirements may lead to lower compartment performance and/or compartment failure. Problems/failures that are caused by using fuels that do not meet the minimum recommended and/or required performance level are not Cat factory defects and therefore are NOT covered by the Cat warranty. The fuel supplier and customer are responsible.