Information injection-pump assembly

BOSCH

9 400 618 123

9400618123

ZEXEL

106871-3922

1068713922

HINO

220005142A

220005142a

Rating:

Service parts 106871-3922 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001602A

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)/21.6(220)

15.

NOZZLE SET

Include in #1:

106871-3922

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 123

9400618123

ZEXEL

106871-3922

1068713922

HINO

220005142A

220005142a

Zexel num

Bosch num

Firm num

Name

106871-3922

9 400 618 123

220005142A HINO

INJECTION-PUMP ASSEMBLY

EF550 A * K

EF550 A * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112.5

110.5

114.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

129

126

132

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

130.5

127.5

133.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

110

104

116

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

10+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(860)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

Test data Ex:

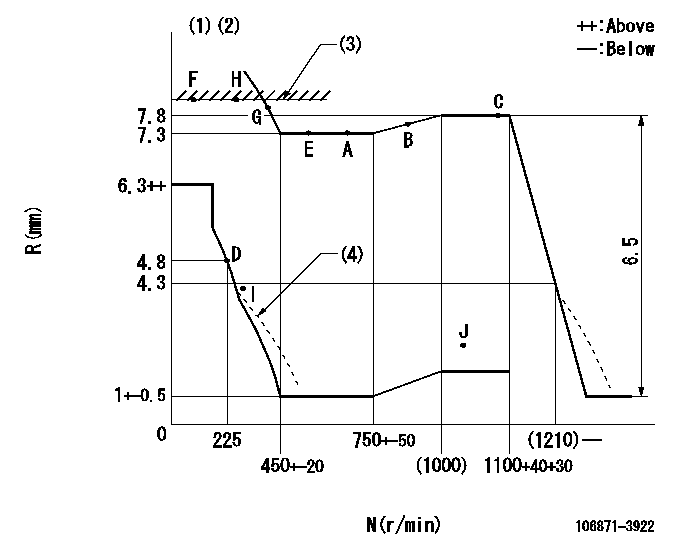

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT

(4)Damper spring setting: DL

----------

RT=0.8 TH=2mm DL=3.8-0.5mm

----------

----------

RT=0.8 TH=2mm DL=3.8-0.5mm

----------

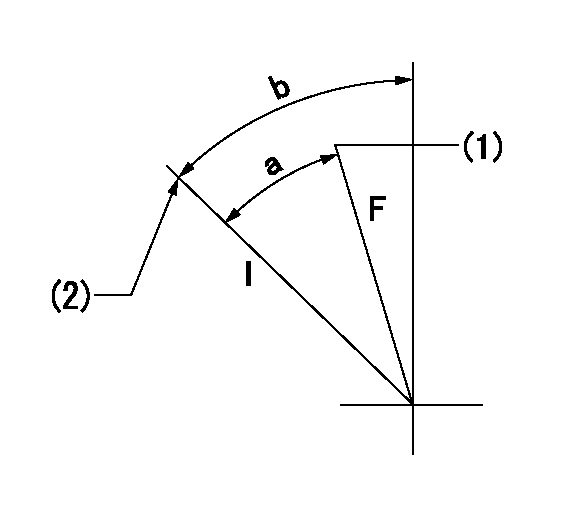

Speed control lever angle

F:Full speed

----------

----------

a=19deg+-5deg

----------

----------

a=19deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=34deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=34deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Illustration 5 g01380327

Install support (18) with two bolts (1) and two hard washers (13). Tighten the two bolts to a torque of 47 9 N m (35 7 lb ft).

Install support assembly (21) with three bolts (14) and three hard washers (13). Tighten the three bolts to a torque of 47 9 N m (35 7 lb ft).

Install elbow assembly (22) with two bolts (9) and two hard washers (6). Install the elbow assembly to the turbocharger outlet by using the proper seals and the proper procedure. Tighten the two bolts to a torque of 55 10 N m (40 7 lb ft).

Position clamp assembly (20) between support assembly (21) and elbow assembly (22). Secure the clamp assembly with two bolts (9), four hard washers (6), and two nuts (7). Tighten the two bolts to a torque of 55 10 N m (40 7 lb ft).

Illustration 6 g01380335

Illustration 7 g01380344

Position Diesel Particulate Filter Gp (17) on the brackets.Note: Remove material from the hood assembly, as necessary, to avoid interference with the diesel particulate filter. Refer to Illustration 6.

Secure the Diesel Particulate Filter by using clamp (19). Secure clamp (19) to clamp assembly (20) with one bolt (4), two hard washers (13), and one nut (2). Tighten the bolt to a torque of 47 9 N m (35 7 lb ft).

Secure the other end of clamp (19) to clamp assembly (20) and support assembly (21) with one bolt (15), two hard washers (13), and one nut (2). Tighten the bolt to a torque of 47 9 N m (35 7 lb ft).Note: The inlet and outlet caps can be rotated in order to align with the elbow and the exhaust stack by loosening the band clamps. Tighten the band clamps after alignment is correct.

Install clamp assembly (16) in order to secure the Diesel Particulate Filter to the elbow assembly.

Illustration 8 g01380346

Install the other end of the Diesel Particulate Filter to support (18) with two bolts (10), four hard washers (6), and two nuts (7). Tighten the two bolts to a torque of 55 10 N m (40 7 lb ft).

Secure support (18) to support assembly (25) with two bolts (8), four hard washers (11), and two nuts (12). Tighten the two bolts to a torque of 100 20 N m (75 15 lb ft).

Secure ejector line (26) with two bolts (5), four hard washers (13), and two nuts (2). Tighten the two bolts to a torque of 47 9 N m (35 7 lb ft).

Illustration 9 g01383124

Typical Example for Installing the Exhaust Monitor Group

Illustration 10 g01425177

Typical Example for Installing the Exhaust Monitor Group (Shown With Pipe Elbow (3) Installed)

Install 302-1563 Exhaust Monitor Gp (25) (from Exhaust Monitor Group (23) ) in the cab.

Illustration 11 g01380354

Install the thermocouple and the pressure sensor tube (part of the 216-7990 Installation Assembly ) at the Diesel Particulate Filter. Refer to Special Instruction, REHS1807 under the topic "Connection for the Thermocouple and

Have questions with 106871-3922?

Group cross 106871-3922 ZEXEL

Hino

Hino

106871-3922

9 400 618 123

220005142A

INJECTION-PUMP ASSEMBLY

EF550

EF550