Information injection-pump assembly

ZEXEL

106871-3921

1068713921

HINO

220005141A

220005141a

Rating:

Cross reference number

ZEXEL

106871-3921

1068713921

HINO

220005141A

220005141a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

112.5

110.5

114.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.6

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

129

126

132

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

130.5

127.5

133.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

110

104

116

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

10+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

(875)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1075

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

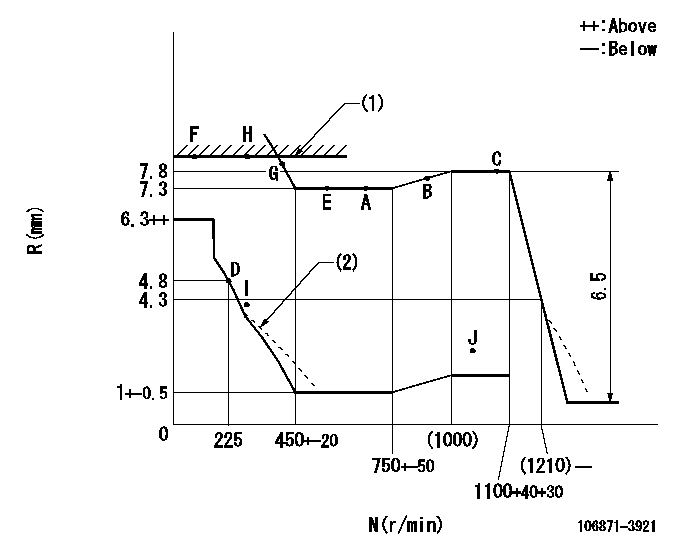

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Damper spring setting: DL

----------

DL=3.8-0.5mm

----------

----------

DL=3.8-0.5mm

----------

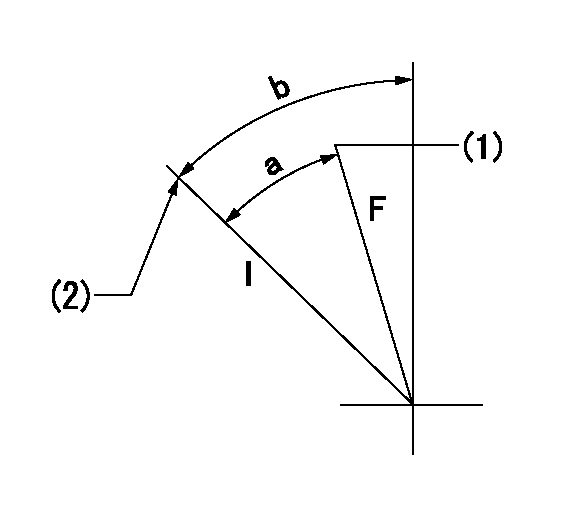

Speed control lever angle

F:Full speed

----------

----------

a=19deg+-5deg

----------

----------

a=19deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=34deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=34deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

Fuel Return Manifold Leaks and/or Leaks at Fuel Return Boots or Connectors ... Remove the valve cover(s). Make a visual inspection of the fuel return manifold, fuel return boots, and connectors. Boots and/or connectors with damage, or wrongly installed, will let fuel get into the oil. If you do not see leaks during the visual inspection, start the engine and visually inspect while the engine is running. Boots and/or connectors can cause leakage if the fuel return line has a restriction.Loose Fuel Injection Nozzle Nut(s) ... A loose fuel injection nozzle nut can cause fuel leakage. Tighten nozzle nut(s) to 30 5 lb. ft. (4,1 0,7 mkg).Defective Fuel Nozzle(s) ... Check fuel nozzle(s) for cracks in inlet fitting, inlet line, or nozzle body. If you do not see a crack, start the engine and visually inspect each nozzle for leaks. Cracks in the inlet fitting and nozzle body are nozzle defects. Cracks in the inlet line are caused by the nozzle not being tightened correctly.Defective Diaphragm in Fuel Transfer Pump ... A defective diaphragm will cause fuel leakage through the orifice in the fuel transfer pump housing. If you do not see leakage, make sure the orifice is open. Start the engine and again look for possible leakage. If the pump has leaks, install a new pump.Loose Fuel Injection Pump Retaining Bushing ... Loose retaining bushings will not hold the barrel of the injection pump correctly against the seat in the pump housing and fuel can get into the crankcase. A loose bushing can cause the engine to misfire or cause fuel leakage to the outside of the pump housing. Remove the fuel lines at the fuel injection pump and tighten each retaining bushing to 100 10 lb. ft. (13,8 1,4 mkg). To tighten the three rear retaining bushings the pump housing must be removed from the engine.Fuel Leaks Between Injection Pump Barrel(s) and Injection Pump Housing ... Dirt or foreign material under the barrel of the fuel injection pump will cause fuel leakage into the crankcase. Remove the housing of the fuel injection pump and the governor from the engine. Remove the plunger and barrel assemblies from the pump housing. Inspect the seat area of the barrel and housing. Be sure the seat is smooth and flat. Check the timing dimension and adjust as necessary. Install the fuel injection pumps. *Worn Fuel Injection Pumps ... It is possible for one or more of the plunger and barrel assemblies to be worn enough to cause fuel leakage between the plunger and barrel. Remove the housing of the fuel injection pump and the governor from the engine. Test the fuel injection pump on the test bench for fuel injection pumps. If a test bench is not available, install new plunger and barrel assemblies in place of those with damage.*Authorized dealers are equipped with the necessary tools and personnel familiar with disassembly and assembly procedures to perform these services.