Information injection-pump assembly

BOSCH

9 400 618 121

9400618121

ZEXEL

106871-3892

1068713892

HINO

220004882A

220004882a

Rating:

Cross reference number

BOSCH

9 400 618 121

9400618121

ZEXEL

106871-3892

1068713892

HINO

220004882A

220004882a

Zexel num

Bosch num

Firm num

Name

106871-3892

9 400 618 121

220004882A HINO

INJECTION-PUMP ASSEMBLY

EF750 A * K

EF750 A * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2+-0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

138

144

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

142

136

148

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.9

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

131

128

134

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

10.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

150

160

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

7.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

124

118

130

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(860)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

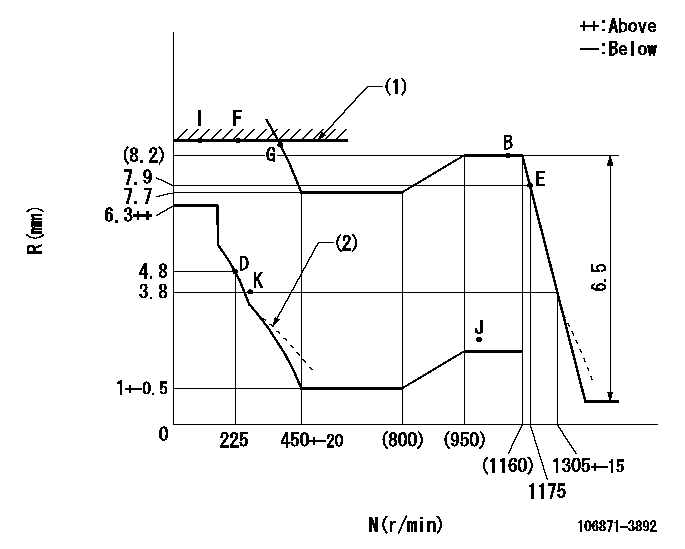

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Damper spring setting: DL

----------

DL=3.8-0.5mm

----------

----------

DL=3.8-0.5mm

----------

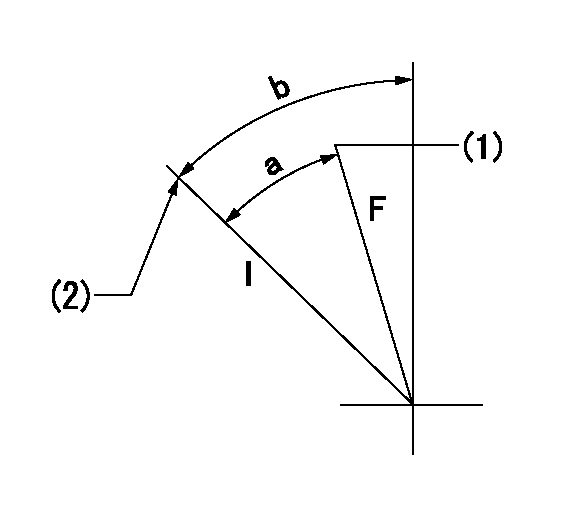

Speed control lever angle

F:Full speed

----------

----------

a=22deg+-5deg

----------

----------

a=22deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Mount the joint (B).

(2)Select the shim (D) so that the rack limit's rack position is obtained at that time.

(3)Install the rod (E) to the block (C).

The distance between the pump end face and the rod (E) at rack limit must be L.

2. Rack sensor adjustment (-0020)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set at speed N.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.01 (V), then tighten the nut (F). (If equipped with a boost compensator, perform with boost pressure applied.)

(5)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(6)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=38-0.2mm N=1100r/min Ra=(8.2)mm

----------

----------

L=38-0.2mm N=1100r/min Ra=(8.2)mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

The lubrication system consists of the suction tube, oil pump, cooler, filters, internal engine passages and the oil pan. The pan can be turned end-for-end to provide either a front or rear sump. The dipstick placement and suction tube length correspond with sump location. A longer suction tube and support is required when the pan is positioned for a rear sump.The oil pump draws lubricant from the sump and forces it through the oil cooler, oil filters, and then into the oil manifold. Oil flows through connecting passages to lubricate the engine components. A bypass valve in the pump controls the maximum pressure of the oil from the pump. As oil temperature increases, oil viscosity and pressure decreases and the oil filter bypass valve closes. Now, only filtered oil is delivered to the engine components. Oil temperature continues to increase and the oil cooler bypass valve closes. Oil now flows through the oil cooler and oil filter before reaching the engine components.A contaminated or restricted oil filter element will not prevent lubricating oil from being delivered to the engine components. The oil filter bypass valve will open, allowing oil to bypass the filter element.An oil manifold, cast into the cylinder block, directs lubricant to the camshaft journals and main bearing supply passages. Oil is also directed up through the cylinder head to lubricate the valve rocker arm shafts.The connecting rod bearings receive oil through drilled passages in the crankshaft between the main bearing journals and connecting rod journals.When the engine is warm and running at rated speed, the oil pressure gauge should register in the "operating range" (58 to 72 psi). A low pressure reading is normal at idling speeds.Some engines may be equipped with an auxiliary or remote mounted by-pass filter system. This system must be connected so part of the oil continuously circulates through the by-pass filter, from the crankcase lubricating oil pump. An orifice on the outlet or clean side of the filter restricts the flow of oil through the by-pass filter so that full oil pressure is available to all parts of the engine. Filtered oil from the by-pass filter is returned to the crankcase sump. The by-pass filter must never be used in place of the factory installed full flow filter.

COLD START

COLD START

Have questions with 106871-3892?

Group cross 106871-3892 ZEXEL

Hino

106871-3892

9 400 618 121

220004882A

INJECTION-PUMP ASSEMBLY

EF750

EF750