Information injection-pump assembly

BOSCH

9 400 618 120

9400618120

ZEXEL

106871-3881

1068713881

HINO

220004871A

220004871a

Rating:

Cross reference number

BOSCH

9 400 618 120

9400618120

ZEXEL

106871-3881

1068713881

HINO

220004871A

220004871a

Zexel num

Bosch num

Firm num

Name

106871-3881

9 400 618 120

220004871A HINO

INJECTION-PUMP ASSEMBLY

EF750 K

EF750 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

-

Rack position

10.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

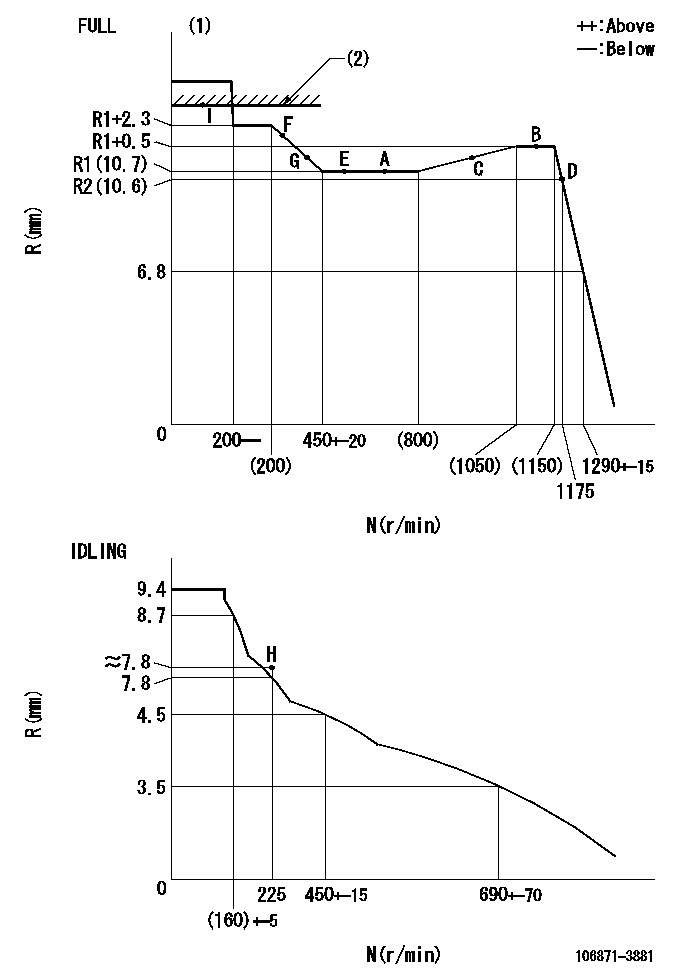

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.7)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

135

147

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1+0.2)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

137

131

143

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2(10.6)

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

126

121

131

Fixing the lever

*

Injection quantity adjustment_07

Adjusting point

I

Rack position

13.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

150

160

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_08

Adjusting point

E

Rack position

R1(10.7)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

124

118

130

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(860)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B75

----------

----------

T1=B75

----------

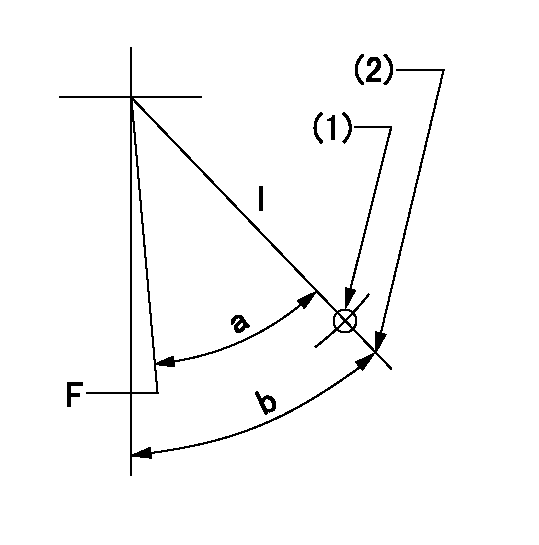

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=38mm

----------

a=(36deg)+-3deg b=38deg+-5deg

----------

aa=38mm

----------

a=(36deg)+-3deg b=38deg+-5deg

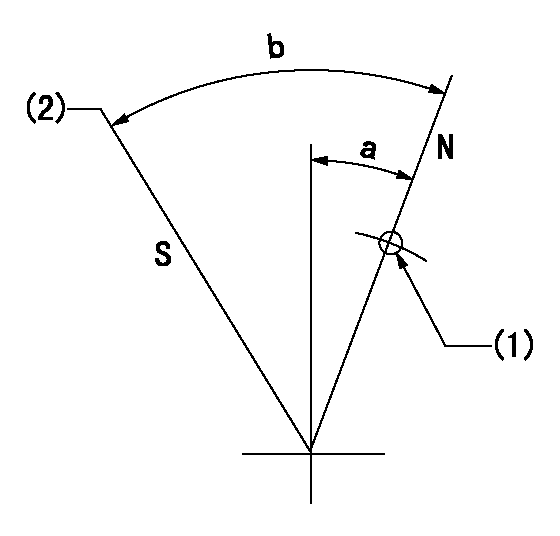

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper screw at rack position = bb

----------

aa=45mm bb=4mm

----------

a=19deg+-5deg b=(37.5deg)+-5deg

----------

aa=45mm bb=4mm

----------

a=19deg+-5deg b=(37.5deg)+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

The following topics describe care and maintenance of the electrical system components. These components functioning together produce the energy needed for operating the electrical equipment on the truck and each is dependent upon the other for satisfactory operation. In the event of failure or improper operation, it is essential to check the entire electrical system as a defect in one component can cause damage to another.Many electrical system problems can be traced to loose or corroded connections. Keep connections tight and make sure the wiring insulation is in satisfactory condition. Most of electrical system testing can be performed on the vehicle. (It should be remembered, if a malfunction is found on a vehicle test, the component may need further testing, repair or replacement.) Installations will have electrical components not furnished by Caterpillar. Consult the vehicle manufacturer's manual for maintenance procedures.Check the electrolyte level of each cell and the general condition of the battery. Maintain the electrolyte level to the base of each vent well. The make-up water must be one of the following (in order of preference): 1. Distilled water.2. Odorless, tasteless drinking water.3. Iron free water.4. Any available water.

Never add acid or electrolyte.

CLEANING BATTERY: Mix a weak solution of baking soda and water. Be careful not to get cleaning solution into battery. Apply the solution with a soft bristle brush.

CLEANING BATTERY TERMINALSThoroughly rinse the battery and battery tray with clean water. Apply grease to the battery cable clamps and terminals and to all threads. Testing The Electrolyte Solution: The general condition of a battery can be determined by measuring the specific gravity of the electrolyte solution and adjusting the reading to 80°F (27°C). If the electrolyte level is too low to allow taking a hydrometer reading, add make-up water to the correct level and then charge the battery 2 to 4 hours before taking a reading.

TESTING ELECTROLYTE SOLUTION1. Insert the hydrometer into a cell. Fill the hydrometer barrel while holding it vertically. The float must not drag on the wall of the barrel.2. Read the hydrometer: 1.250 or above - fully charged battery cell1.250-1.225 - full to half charged battery cell1.225-1.150 - half to low charged battery cellBelow 1.150 - dead cell1.000 - water3. Test each cell in the same manner.4. If there is more than .050 (50 gravity points) variation between the highest and lowest reading, the battery may need to be replaced.5. Adjust the readings to 80°F (27°C). a. For every 10F° (5.5C°) the electrolyte temperature is above 80°F (27°C), add .004 (4 gravity points) to the specific gravity readings.b. For every 10F°(5.5C°) the electrolyte temperature is below 80°F (27°C), subtract .004 (4 gravity points) from the specific gravity reading.The corrected reading is of most importance during cold weather when the hydrometer reading is always corrected to a lower specific gravity reading. A low reading signifies the battery has less available power to crank the engine and that booster batteries may be required. Voltage Test (After Load): A load test should be made on a

Never add acid or electrolyte.

CLEANING BATTERY: Mix a weak solution of baking soda and water. Be careful not to get cleaning solution into battery. Apply the solution with a soft bristle brush.

CLEANING BATTERY TERMINALSThoroughly rinse the battery and battery tray with clean water. Apply grease to the battery cable clamps and terminals and to all threads. Testing The Electrolyte Solution: The general condition of a battery can be determined by measuring the specific gravity of the electrolyte solution and adjusting the reading to 80°F (27°C). If the electrolyte level is too low to allow taking a hydrometer reading, add make-up water to the correct level and then charge the battery 2 to 4 hours before taking a reading.

TESTING ELECTROLYTE SOLUTION1. Insert the hydrometer into a cell. Fill the hydrometer barrel while holding it vertically. The float must not drag on the wall of the barrel.2. Read the hydrometer: 1.250 or above - fully charged battery cell1.250-1.225 - full to half charged battery cell1.225-1.150 - half to low charged battery cellBelow 1.150 - dead cell1.000 - water3. Test each cell in the same manner.4. If there is more than .050 (50 gravity points) variation between the highest and lowest reading, the battery may need to be replaced.5. Adjust the readings to 80°F (27°C). a. For every 10F° (5.5C°) the electrolyte temperature is above 80°F (27°C), add .004 (4 gravity points) to the specific gravity readings.b. For every 10F°(5.5C°) the electrolyte temperature is below 80°F (27°C), subtract .004 (4 gravity points) from the specific gravity reading.The corrected reading is of most importance during cold weather when the hydrometer reading is always corrected to a lower specific gravity reading. A low reading signifies the battery has less available power to crank the engine and that booster batteries may be required. Voltage Test (After Load): A load test should be made on a

Have questions with 106871-3881?

Group cross 106871-3881 ZEXEL

Hino

106871-3881

9 400 618 120

220004871A

INJECTION-PUMP ASSEMBLY

EF750

EF750