Information injection-pump assembly

BOSCH

9 400 618 118

9400618118

ZEXEL

106871-3861

1068713861

HINO

220004851A

220004851a

Rating:

Cross reference number

BOSCH

9 400 618 118

9400618118

ZEXEL

106871-3861

1068713861

HINO

220004851A

220004851a

Zexel num

Bosch num

Firm num

Name

106871-3861

9 400 618 118

220004851A HINO

INJECTION-PUMP ASSEMBLY

EF750 A * K

EF750 A * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2+-0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

138

144

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

142

136

148

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.9

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

131

128

134

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

10.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

150

160

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

7.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

124

118

130

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(860)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

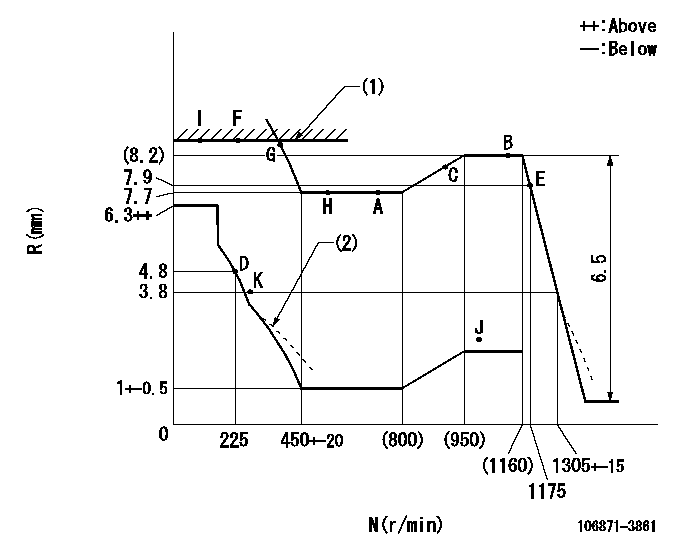

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Damper spring setting: DL

----------

DL=3.8-0.5mm

----------

----------

DL=3.8-0.5mm

----------

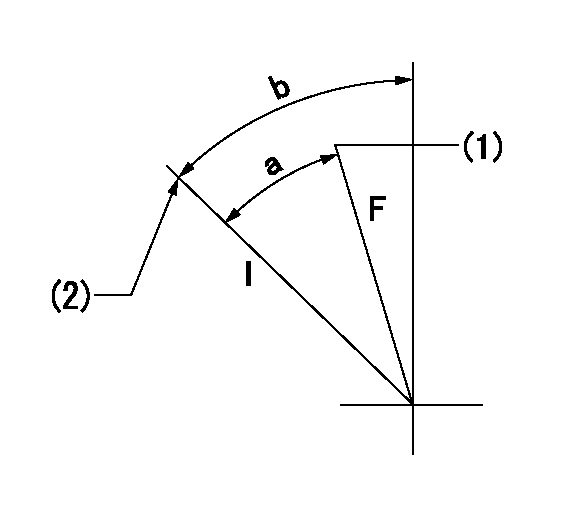

Speed control lever angle

F:Full speed

----------

----------

a=22deg+-5deg

----------

----------

a=22deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Set the stopper bolt (apply red paint).

(4)Free (at shipping)

----------

aa=12mm bb=3mm

----------

a=(15deg) b=48deg+-5deg c=26deg+-5deg

----------

aa=12mm bb=3mm

----------

a=(15deg) b=48deg+-5deg c=26deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

General Instructions

These instructions are a review of many items which a serviceman encounters in servicing and maintaining a truck engine.PROBLEM ANALYZING: In analyzing a system malfunction, use this systematic procedure to locate and correct the problem.1. Determine problem.2. List possible causes.3. Devise checks.4. Conduct checks in logical order to determine cause.5. Consider remaining service life against cost of parts and labor.6. Make necessary repair.7. Recheck.SAFETY: Your safety and that of others is always the number one consideration when servicing or maintaining trucks and truck engines. Safety is a matter of thoroughly understanding the job to be done and the application of good common sense. It is not just a matter of "do's" and "don'ts".CLEANLINESS: The most important single item in assuring long engine life is to keep dirt out of vital working parts. Precautions have been taken to safeguard against this. Enclosed compartments, seals and filters have been provided to keep the supply of air, fuel, coolant and lubricants clean. It is important that these safeguards be maintained.Whenever fuel, lubricating oil, coolant lines or air lines are disconnected, clean the point of disconnection as well as the adjacent area. As soon as the disconnection is made, cap, plug or tape the line or opening to prevent entry of foreign material. The same recommendations for cleaning and covering apply when access covers or inspection plates are removed.Clean and inspect all parts. Be sure all passages and holes are open. Cover all parts to keep them clean. Be sure parts are clean when they are installed. Leave new parts in their containers until ready for assembly.REMOVAL AND INSTALLATION: Use a hoist to remove heavy components. Engine removal should be accomplished by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other and as near perpendicular as possible to the top of the object being lifted. When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt diminishes as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only have stress in tension.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.If a part resists removal, check to be certain all nuts and bolts have been removed and that an adjacent part is not interfering.DISASSEMBLY AND ASSEMBLY: When servicing or repairing the engine, complete each step in turn. Do not partially assemble one part and start assembling some other part. Make all adjustments as recommended. Always check the job after it is completed to see nothing has been overlooked.BOLTS AND BOLT TORQUE: Use bolts of the correct length. A bolt which is too long may "bottom" before the head is tight against the part it is to hold and cause failure. The threads in the assembly can also become damaged when a "long" bolt is used.If a bolt is too short, there may not be enough threads

These instructions are a review of many items which a serviceman encounters in servicing and maintaining a truck engine.PROBLEM ANALYZING: In analyzing a system malfunction, use this systematic procedure to locate and correct the problem.1. Determine problem.2. List possible causes.3. Devise checks.4. Conduct checks in logical order to determine cause.5. Consider remaining service life against cost of parts and labor.6. Make necessary repair.7. Recheck.SAFETY: Your safety and that of others is always the number one consideration when servicing or maintaining trucks and truck engines. Safety is a matter of thoroughly understanding the job to be done and the application of good common sense. It is not just a matter of "do's" and "don'ts".CLEANLINESS: The most important single item in assuring long engine life is to keep dirt out of vital working parts. Precautions have been taken to safeguard against this. Enclosed compartments, seals and filters have been provided to keep the supply of air, fuel, coolant and lubricants clean. It is important that these safeguards be maintained.Whenever fuel, lubricating oil, coolant lines or air lines are disconnected, clean the point of disconnection as well as the adjacent area. As soon as the disconnection is made, cap, plug or tape the line or opening to prevent entry of foreign material. The same recommendations for cleaning and covering apply when access covers or inspection plates are removed.Clean and inspect all parts. Be sure all passages and holes are open. Cover all parts to keep them clean. Be sure parts are clean when they are installed. Leave new parts in their containers until ready for assembly.REMOVAL AND INSTALLATION: Use a hoist to remove heavy components. Engine removal should be accomplished by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other and as near perpendicular as possible to the top of the object being lifted. When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt diminishes as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only have stress in tension.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling.If a part resists removal, check to be certain all nuts and bolts have been removed and that an adjacent part is not interfering.DISASSEMBLY AND ASSEMBLY: When servicing or repairing the engine, complete each step in turn. Do not partially assemble one part and start assembling some other part. Make all adjustments as recommended. Always check the job after it is completed to see nothing has been overlooked.BOLTS AND BOLT TORQUE: Use bolts of the correct length. A bolt which is too long may "bottom" before the head is tight against the part it is to hold and cause failure. The threads in the assembly can also become damaged when a "long" bolt is used.If a bolt is too short, there may not be enough threads

Have questions with 106871-3861?

Group cross 106871-3861 ZEXEL

Hino

106871-3861

9 400 618 118

220004851A

INJECTION-PUMP ASSEMBLY

EF750

EF750