Information injection-pump assembly

BOSCH

9 400 618 116

9400618116

ZEXEL

106871-3821

1068713821

HINO

220004801A

220004801a

Rating:

Service parts 106871-3821 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236001530B

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)

15.

NOZZLE SET

Include in #1:

106871-3821

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 116

9400618116

ZEXEL

106871-3821

1068713821

HINO

220004801A

220004801a

Zexel num

Bosch num

Firm num

Name

106871-3821

9 400 618 116

220004801A HINO

INJECTION-PUMP ASSEMBLY

EF750 * K 14CD PE8P PE

EF750 * K 14CD PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1020

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.4

4.34

4.4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

120

117

123

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.6

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

121.8

119.8

123.8

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

145

142

148

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11.5

8.5

14.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

160

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3.5

3.2

3.8

Remarks

Finish

Finish

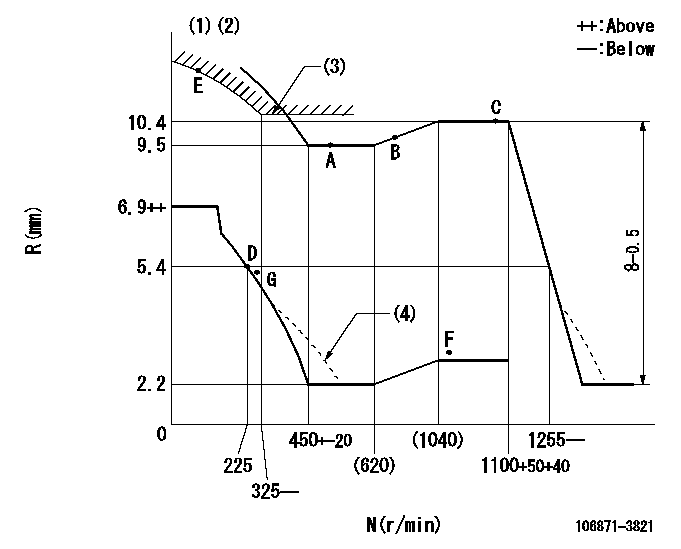

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting: DL

----------

RT=0.8 TH=2.7mm SXL=10.4+0.2mm DL=4.4-0.2mm

----------

----------

RT=0.8 TH=2.7mm SXL=10.4+0.2mm DL=4.4-0.2mm

----------

Speed control lever angle

F:Full speed

----------

----------

a=17deg+-5deg

----------

----------

a=17deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=50mm

----------

a=39deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=39deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

This engine has an exhaust driven turbocharger to provide compacted air to the cylinders.The exhaust gases enter the turbine housing and are directed through the blades of a turbine wheel, causing the turbine wheel and a compressor wheel to rotate.Filtered inlet air from the air cleaner is drawn through the air inlet of the compressor housing by the rotating compressor wheel. The air is forced through the aftercooler to the inlet manifold of the engine and is compressed by action of the compressor impeller.When the intake air passes through and is compressed by the turbocharger, it becomes heated and becomes less dense. By directing air through the aftercooler located between the turbocharger and the inlet manifold, some of that heat is removed from the air. The aftercooler is a simple device resembling a small radiator core. Coolant from the engine passes through the core tubes and the compressed air is directed around the tubes. Since the temperature of the coolant is lower than the air, the air is cooled as it leaves the aftercooler. This means more air (oxygen) is available for combustion, resulting in more fuel being burned and more power produced.When engine load increases, more fuel is injected into the engine cylinders. The increased volume of exhaust gas causes the turbocharger turbine wheel and compressor impeller to rotate faster. The higher RPM of the impeller increases the quantity of inlet air. As the turbocharger provides additional inlet air, more fuel can be burned; hence more horsepower derived from the engine.The turbocharger is mounted to the engine exhaust manifold. All the exhaust gases from the diesel engine pass through the turbocharger.The turbocharger bearings are pressure-lubricated by engine oil. The oil enters the top of the center section and is directed through passages to lubricate the thrust bearing, sleeves and the journal bearings of the turbocharger. Oil leaves the turbocharger through a port in the bottom of the center section and is returned to the engine sump.

CROSS SECTION OF THE TURBOCHARGERMaximum turbocharger speed is determined by the rack setting, the high idle speed setting and the altitude at which the engine is operated. The high idle speed and the rack setting are not the same for all altitudes.

If the high idle speed or the rack setting is greater than specified for the altitude at which the engine is operated, damage to engine or turbocharger parts can result.

The fuel pump rack has been set by qualified personnel for a particular engine application. The governor housing and turbocharger are sealed to prevent unqualified personnel from tampering with the adjustments.The engine can be operated at a lower altitude than specified without danger of engine damage. In this situation the engine will perform at slightly less than maximum efficiency. When operated at a higher altitude, the rack setting and high idle speed setting must be changed.The principal cause of fouled valves, damaged bearings, worn piston rings and cylinder liners is the entrance of airborne foreign matter into the engine cylinders; therefore,

CROSS SECTION OF THE TURBOCHARGERMaximum turbocharger speed is determined by the rack setting, the high idle speed setting and the altitude at which the engine is operated. The high idle speed and the rack setting are not the same for all altitudes.

If the high idle speed or the rack setting is greater than specified for the altitude at which the engine is operated, damage to engine or turbocharger parts can result.

The fuel pump rack has been set by qualified personnel for a particular engine application. The governor housing and turbocharger are sealed to prevent unqualified personnel from tampering with the adjustments.The engine can be operated at a lower altitude than specified without danger of engine damage. In this situation the engine will perform at slightly less than maximum efficiency. When operated at a higher altitude, the rack setting and high idle speed setting must be changed.The principal cause of fouled valves, damaged bearings, worn piston rings and cylinder liners is the entrance of airborne foreign matter into the engine cylinders; therefore,

Have questions with 106871-3821?

Group cross 106871-3821 ZEXEL

Hino

106871-3821

9 400 618 116

220004801A

INJECTION-PUMP ASSEMBLY

EF750

EF750