Information injection-pump assembly

BOSCH

9 400 618 114

9400618114

ZEXEL

106871-3801

1068713801

HINO

220004761A

220004761a

Rating:

Service parts 106871-3801 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1602

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

15.

NOZZLE SET

Include in #1:

106871-3801

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 114

9400618114

ZEXEL

106871-3801

1068713801

HINO

220004761A

220004761a

Zexel num

Bosch num

Firm num

Name

106871-3801

9 400 618 114

220004761A HINO

INJECTION-PUMP ASSEMBLY

EF750 A * K 14CD PE8P PE

EF750 A * K 14CD PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2+-0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

138

144

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

142

136

148

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.9

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

131

128

134

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

10.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

150

160

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

7.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

124

118

130

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(860)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

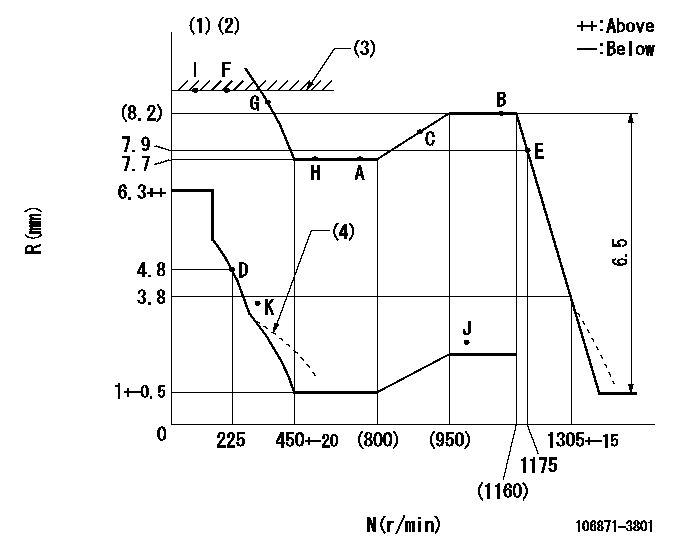

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT

(4)Damper spring setting: DL

----------

RT=0.8 TH=2.2mm DL=3.8-0.5mm

----------

----------

RT=0.8 TH=2.2mm DL=3.8-0.5mm

----------

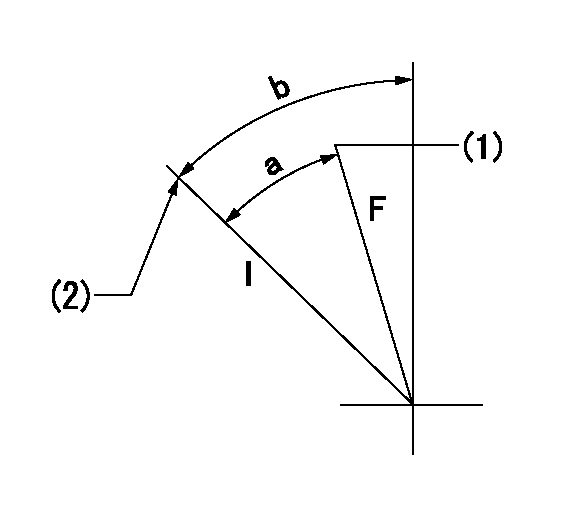

Speed control lever angle

F:Full speed

----------

----------

a=22deg+-5deg

----------

----------

a=22deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

To many, the diesel principle may not be new, however, the special features of Caterpillar Diesel Truck Engines require that the operator and the maintenance personnel become acquainted with the systems in order to give the engine the best possible care. Maximum service depends a great deal on a good maintenance schedule performed by reliable personnel with a basic understanding of the working principles and systems.Diesel Engine Principle

This diesel engine operates on the reciprocating piston 4-stroke cycle, compression ignition principle, and burns fuels commercially known as diesel fuels. The basic difference between the spark ignition engine and the diesel engine are; the method of introducing fuel into the system, and the method by which the fuel is ignited.The diesel engine always takes a full charge of "air only" on each inlet stroke, compresses it in an extremely small space causing the air to reach temperatures over 1000°F (537°C). Fuel is injected into the precombustion chamber as the piston nears the top of the compression stroke, where it mixes with the compressed air, and immediately starts to burn. This is called self-ignition, or spontaneous ignition. The expansion of the burning gases forces the piston down on a power stroke. Four Stroke Cycle Principle:

The four stroke cycle engine has separate strokes for each basic function. The four strokes and the order in which they occur are: Intake, compression, power and exhaust.It must be remembered that for the four stroke cycle to function, the inlet valves, exhaust valves, and fuel injection must be timed in proper sequence with the piston. This is accomplished by timing gears between the crankshaft, the valve train, and injection pumps. Intake Stroke: As the piston moves down on the inlet stroke the inlet valves are opened and exhaust valves are closed by the camshaft and rocker arm arrangement. Air is drawn in through the air cleaner by the turbocharger and forced through the water cooled aftercooler and then charges the cylinder through the intake valves. Compression Stroke: At the end of the intake stroke both inlet valves close and the exhaust valves remain closed. As the

This diesel engine operates on the reciprocating piston 4-stroke cycle, compression ignition principle, and burns fuels commercially known as diesel fuels. The basic difference between the spark ignition engine and the diesel engine are; the method of introducing fuel into the system, and the method by which the fuel is ignited.The diesel engine always takes a full charge of "air only" on each inlet stroke, compresses it in an extremely small space causing the air to reach temperatures over 1000°F (537°C). Fuel is injected into the precombustion chamber as the piston nears the top of the compression stroke, where it mixes with the compressed air, and immediately starts to burn. This is called self-ignition, or spontaneous ignition. The expansion of the burning gases forces the piston down on a power stroke. Four Stroke Cycle Principle:

The four stroke cycle engine has separate strokes for each basic function. The four strokes and the order in which they occur are: Intake, compression, power and exhaust.It must be remembered that for the four stroke cycle to function, the inlet valves, exhaust valves, and fuel injection must be timed in proper sequence with the piston. This is accomplished by timing gears between the crankshaft, the valve train, and injection pumps. Intake Stroke: As the piston moves down on the inlet stroke the inlet valves are opened and exhaust valves are closed by the camshaft and rocker arm arrangement. Air is drawn in through the air cleaner by the turbocharger and forced through the water cooled aftercooler and then charges the cylinder through the intake valves. Compression Stroke: At the end of the intake stroke both inlet valves close and the exhaust valves remain closed. As the

Have questions with 106871-3801?

Group cross 106871-3801 ZEXEL

Hino

106871-3801

9 400 618 114

220004761A

INJECTION-PUMP ASSEMBLY

EF750

EF750