Information injection-pump assembly

ZEXEL

106871-3800

1068713800

HINO

220004760A

220004760a

Rating:

Service parts 106871-3800 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1602

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

15.

NOZZLE SET

Include in #1:

106871-3800

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-3800

1068713800

HINO

220004760A

220004760a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

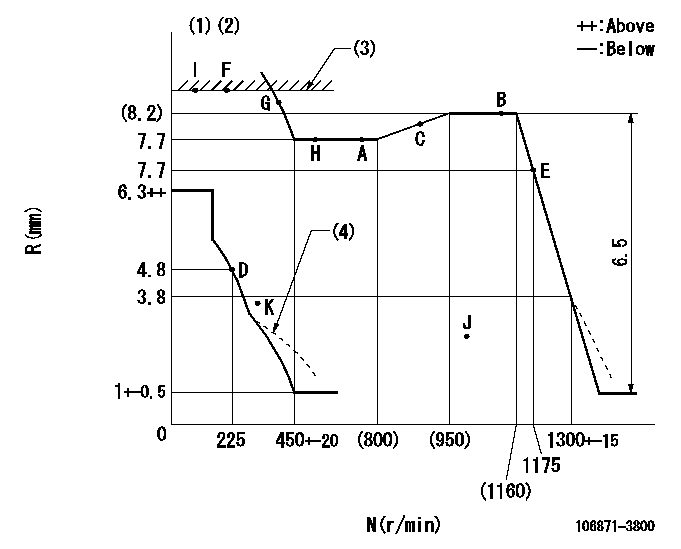

Injection quantity adjustment

Adjusting point

A

Rack position

7.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123

121

125

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2+-0.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

138

144

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

142

136

148

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

-

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.6

9.6

15.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

E

Rack position

7.7

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

134

124

144

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

10.3+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

150

160

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_07

Adjusting point

H

Rack position

7.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

124

118

130

Fixing the lever

*

Timer adjustment

Pump speed

r/min

(875)

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1075

Advance angle

deg.

4.75

4.45

5.05

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT

(4)Damper spring setting: DL

----------

RT=0.8 TH=2.2mm DL=3.8-0.5mm

----------

----------

RT=0.8 TH=2.2mm DL=3.8-0.5mm

----------

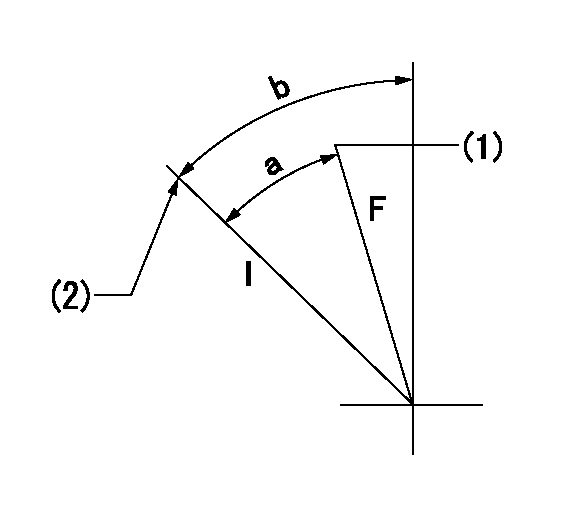

Speed control lever angle

F:Full speed

----------

----------

a=22deg+-5deg

----------

----------

a=22deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

----------

aa=50mm

----------

a=36deg+-3deg b=39deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

AIR COMPRESSOR: The air compressor which supplies pressure air is a two cylinder unit and is gear driven. The moving parts are lubricated from the diesel engine crankcase lubricating oil system. The compressor is liquid cooled and is connected through lines to the diesel engine cooling system.Every 10,000 miles inspect air compressor air cleaner. The time to replace the air compressor air cleaner is determined by inspection. Install a new element if plugged or oil soaked. Replace element every 20,000 miles regardless of condition.

AIR COMPRESSOR AIR CLEANEREvery 100,000 miles rebuild or install a rebuilt or new air compressor. This component should be checked and rebuilt in a well equipped shop with proper tools and personnel familiar with disassembly and assembly procedures. Thoroughly inspect all connections for tightness before placing vehicle in use.DRAIN AIR TANKS: Drain moisture from the air storage tanks at the end of each days run. Open the drain cocks at the bottom of the tank. Some air systems have automatic moisture ejector valves which can also be operated manually. Refer to the truck manufacturer's manual for maintenance procedures.TIGHTEN ENGINE MOUNTING BOLTS: When giving the engine a seasonal check, tighten all mounting bolts and nuts. Replace damaged, broken or lost bolts. See BOLT, NUT AND TAPERLOCK STUD SPECIFICATIONS.Major Inspection Maintenance

These items are of major checks which require partial disassembly and should be performed by experienced personnel. If it is determined that parts are worn beyond limits, remove the engine and completely rebuild.Oil consumption, combustion gas blow by, loss of power, and other signs of wear should be taken into consideration and analyzed to determine if the engine can be operated for another service interval.CRANKSHAFT END CLEARANCE: When engine is being rebuilt or at the 200,000 mile interval, check the crankshaft end clearance. The check can be made by attaching a dial indicator against the crankshaft pulley or vibration damper while prying against the vibration damper and pulley hub. End clearance should not exceed .035 inches (0,89 mm). Do not pry against outer diameter of vibration damper.CRANKSHAFT SEALS: When engine is being rebuilt or at the 300,000 mile interval or if oil leakage is occuring, replace seals.REBUILD CYLINDER HEAD: Irregular engine operation and excessive white or blue smoke can be caused by leaky valves and/or worn valve guides. The cylinder head must be removed for further inspection and reconditioning. Your authorized dealer is equipped to analyze the problem and recondition the cylinder head and valve components.

AIR COMPRESSOR AIR CLEANEREvery 100,000 miles rebuild or install a rebuilt or new air compressor. This component should be checked and rebuilt in a well equipped shop with proper tools and personnel familiar with disassembly and assembly procedures. Thoroughly inspect all connections for tightness before placing vehicle in use.DRAIN AIR TANKS: Drain moisture from the air storage tanks at the end of each days run. Open the drain cocks at the bottom of the tank. Some air systems have automatic moisture ejector valves which can also be operated manually. Refer to the truck manufacturer's manual for maintenance procedures.TIGHTEN ENGINE MOUNTING BOLTS: When giving the engine a seasonal check, tighten all mounting bolts and nuts. Replace damaged, broken or lost bolts. See BOLT, NUT AND TAPERLOCK STUD SPECIFICATIONS.Major Inspection Maintenance

These items are of major checks which require partial disassembly and should be performed by experienced personnel. If it is determined that parts are worn beyond limits, remove the engine and completely rebuild.Oil consumption, combustion gas blow by, loss of power, and other signs of wear should be taken into consideration and analyzed to determine if the engine can be operated for another service interval.CRANKSHAFT END CLEARANCE: When engine is being rebuilt or at the 200,000 mile interval, check the crankshaft end clearance. The check can be made by attaching a dial indicator against the crankshaft pulley or vibration damper while prying against the vibration damper and pulley hub. End clearance should not exceed .035 inches (0,89 mm). Do not pry against outer diameter of vibration damper.CRANKSHAFT SEALS: When engine is being rebuilt or at the 300,000 mile interval or if oil leakage is occuring, replace seals.REBUILD CYLINDER HEAD: Irregular engine operation and excessive white or blue smoke can be caused by leaky valves and/or worn valve guides. The cylinder head must be removed for further inspection and reconditioning. Your authorized dealer is equipped to analyze the problem and recondition the cylinder head and valve components.