Information injection-pump assembly

ZEXEL

106871-3290

1068713290

HINO

220003471C

220003471c

Rating:

Service parts 106871-3290 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1480

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106871-3290

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-3290

1068713290

HINO

220003471C

220003471c

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127.5

118

137

Overflow valve opening pressure

kgf/cm2

1.3

1.2

1.4

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

3.9

3.84

3.9

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

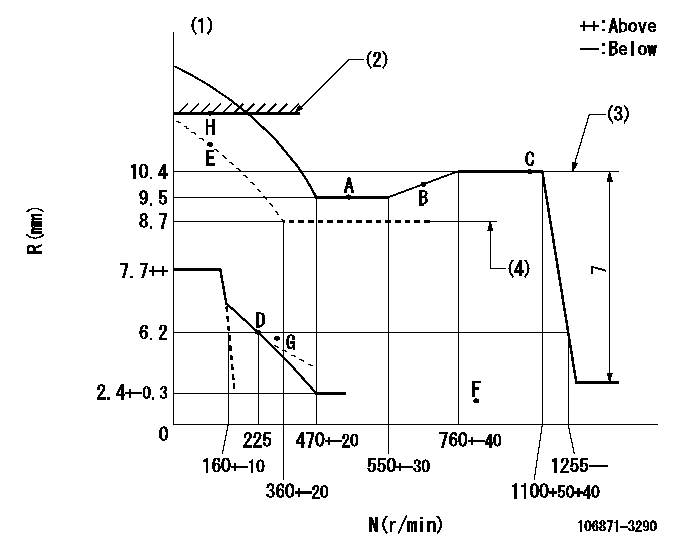

Injection quantity adjustment

Adjusting point

A

Rack position

9.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

128.7

125.7

131.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

146

144

148

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

158.3

155.3

161.3

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.3

10.3

16.3

Max. variation between cylinders

%

0

-1.5

1.5

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

121

121

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

H

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

137.3

137.3

157.3

Fixing the lever

*

Boost pressure

kPa

32

32

Boost pressure

mmHg

240

240

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

8.7

Boost pressure

kPa

4

1.3

6.7

Boost pressure

mmHg

30

10

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

9.5

Boost pressure

kPa

9.3

6.6

12

Boost pressure

mmHg

70

50

90

Timer adjustment

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

1.1

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.5

1.2

1.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)RACK LIMIT: RAL

(3)Boost pressure: not less than BP1

(4)Boost pressure: not less than BP2

----------

DL=4.6-0.2mm RAL=(11.6)mm BP1=240mmHg BP2=0mmHg

----------

----------

DL=4.6-0.2mm RAL=(11.6)mm BP1=240mmHg BP2=0mmHg

----------

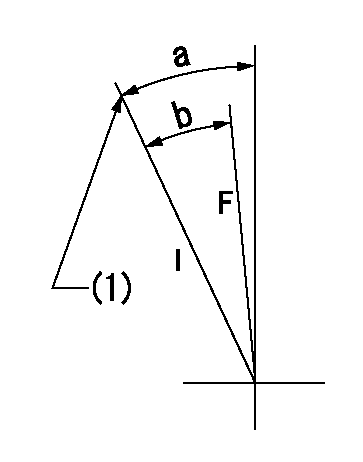

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=29deg+-5deg b=28deg+-3deg

----------

----------

a=29deg+-5deg b=28deg+-3deg

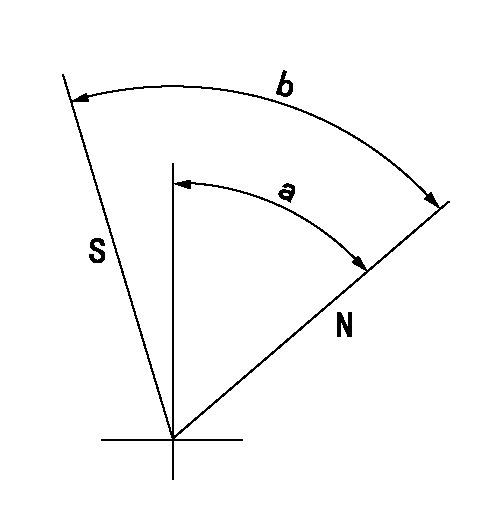

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=39deg+-5deg b=48.5deg+-3deg

----------

----------

a=39deg+-5deg b=48.5deg+-3deg

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Illustration 1 g01955898

Typical exampleThere have been a number of remanufactured 3054C engines that were assembled with a loose 111-3422 Nut (1) for the gear for the injection pump (2). This nut has only received an initial torque of 25 N m (18 lb ft). A second torque of 88 N m (65 lb ft) is required. Without this required torque, the timing of the engine may be affected.The remanufactured part numbers for the engine and serial numbers that have been identified with the loose nut for the fuel injection pump gear are listed in table 1.

Table 1

Part Number of the Engine Arrangement Engine Serial Number

10R-5995 54E09007

54E09008

54E09009

54E09010

54E09011

54E09012

54E09013

54E09063

54E09064

54E09065

54E09066

54E09071

54E09073

54E09074

54E09075

10R-5996 54E09055

54E09056

54E09057

10R-5998 54E09039

54E09058

10R-8791 54E09022

54E09023

54E09024

54E09025

54E09026

54E09028 Solution

The nut that secures the fuel injection pump gear requires a second torque of 88 N m (65 lb ft) prior to engine operation. Refer to Disassembly and Assembly, "Front Cover - Remove and Install" for the correct procedure to remove the front cover. Refer to Disassembly and Assembly, "Fuel Injection Pump - Install" for the correct procedure to tighten the nut.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Illustration 1 g01955898

Typical exampleThere have been a number of remanufactured 3054C engines that were assembled with a loose 111-3422 Nut (1) for the gear for the injection pump (2). This nut has only received an initial torque of 25 N m (18 lb ft). A second torque of 88 N m (65 lb ft) is required. Without this required torque, the timing of the engine may be affected.The remanufactured part numbers for the engine and serial numbers that have been identified with the loose nut for the fuel injection pump gear are listed in table 1.

Table 1

Part Number of the Engine Arrangement Engine Serial Number

10R-5995 54E09007

54E09008

54E09009

54E09010

54E09011

54E09012

54E09013

54E09063

54E09064

54E09065

54E09066

54E09071

54E09073

54E09074

54E09075

10R-5996 54E09055

54E09056

54E09057

10R-5998 54E09039

54E09058

10R-8791 54E09022

54E09023

54E09024

54E09025

54E09026

54E09028 Solution

The nut that secures the fuel injection pump gear requires a second torque of 88 N m (65 lb ft) prior to engine operation. Refer to Disassembly and Assembly, "Front Cover - Remove and Install" for the correct procedure to remove the front cover. Refer to Disassembly and Assembly, "Fuel Injection Pump - Install" for the correct procedure to tighten the nut.