Information injection-pump assembly

ZEXEL

106871-3210

1068713210

HINO

220001306A

220001306a

Rating:

Service parts 106871-3210 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1212

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106871-3210

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-3210

1068713210

HINO

220001306A

220001306a

Zexel num

Bosch num

Firm num

Name

106871-3210

220001306A HINO

INJECTION-PUMP ASSEMBLY

EF700 * K

EF700 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4

3.9

4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-6 deg. 90 89.5 90.5

Cal 1-6 deg. 90 89.5 90.5

Difference between angles 3

Cyl.1-2 deg. 135 134.5 135.5

Cyl.1-2 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-7 deg. 180 179.5 180.5

Cal 1-7 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-4 deg. 270 269.5 270.5

Cal 1-4 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-3 deg. 315 314.5 315.5

Cal 1-3 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

114.6

111.6

117.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

115

113

117

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.2

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

141.2

138.2

144.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.7

10.7

16.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

50

50

50

Average injection quantity

mm3/st.

122

112

132

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Injection quantity adjustment_06

Adjusting point

F

Rack position

-

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

0

Fixing the lever

*

Timer adjustment

Pump speed

r/min

950+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

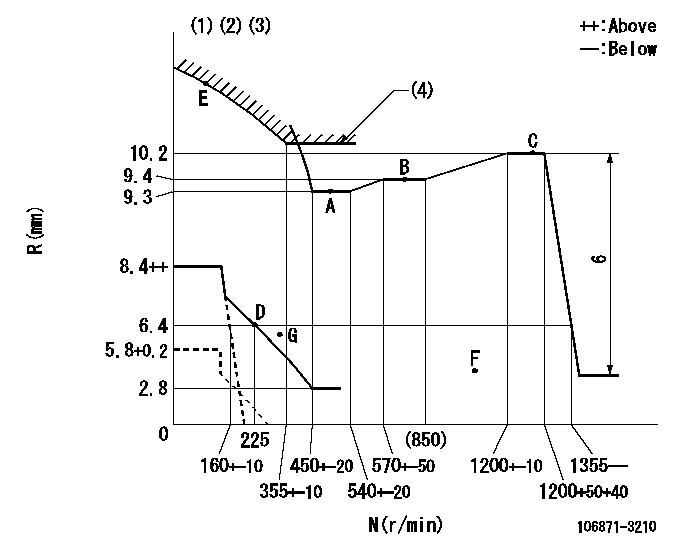

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Set idle at point G (N = N1, R = R1) and confirm that the fuel injection quantity at point F (N = N2) does not exceed Q1.

(3)Set the load lever's stop position so that R = aa (N = 0).

(4)Excess fuel setting for starting: SXL

----------

DL=5.4-0.2mm N1=300r/min R1=5.4mm N2=1000r/min Q1=0mm3/st aa=5.8+0.2mm SXL=10.2+0.2mm

----------

----------

DL=5.4-0.2mm N1=300r/min R1=5.4mm N2=1000r/min Q1=0mm3/st aa=5.8+0.2mm SXL=10.2+0.2mm

----------

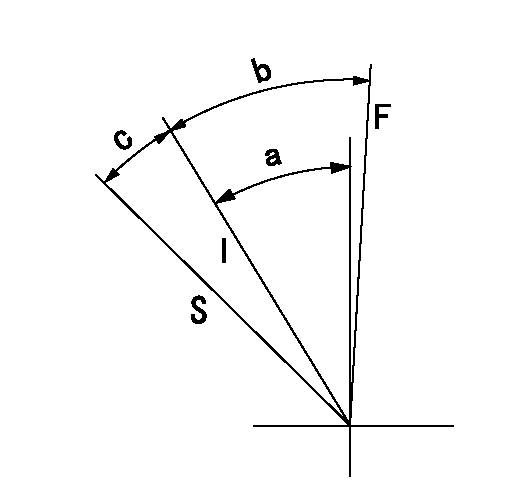

Speed control lever angle

F:Full speed

----------

----------

a=4deg+-5deg

----------

----------

a=4deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=32deg+-5deg b=33deg+-3deg c=19deg+4deg-5deg

----------

----------

a=32deg+-5deg b=33deg+-3deg c=19deg+4deg-5deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325-25r/min Ra=6.4mm

----------

----------

N1=325-25r/min Ra=6.4mm

----------

Information:

Illustration 4 g01621593

(4) The process of crimping has been improved in the location that is shown. The Fifth Improvement

The length of the bolts that secure the fuel transfer pump to the HEUI pump body have increased. The torques on the bolts that secure the transfer pump to the HEUI pump body have also increased in order to improve durability.

HEUI pumps that have been returned from the field have been inspected and broken bolts that connect the fuel transfer pump to the main HEUI pump were found.

The major symptom that is related to this issue is an oil leak between the fuel transfer pump and the HEUI pump.

The bolts that make this connection were lengthened as well as the torques were increased in order to provide a better connection.

This improvement was effective with the following part numbers: 319-0607, 319-0674, 319-0675, 319-0676, 319-0677, 319-0678, 319-0622, 319-0610 and 319-0680

Illustration 5 g01621594

(5) Location of the three bolts that have been lengthened and increased torques have been applied. Note: The applications that utilize an electric fuel transfer pump also have this improvement for the cover that goes in place of the mechanical fuel transfer pump.Note: Refer to Special Instruction , REHS3830 for the following items: parts information, installation of parts and torque procedures that are related to this improvement.All current remanufactured part numbers are being built with the latest improvements. A list of all the current new part numbers and the part numbers of the remanufactured equivalent can be seen below.

Table 1

Current New Part Numbers Remanufactured Equivalent

319-0607 -

319-0674 -

319-0675 10R7145

319-0676 10R7146

319-0677 10R7147

319-0678 10R7148

319-0622 -

319-0610 10R3044

319-0680 - Note: All part numbers that are referenced in this publication were current on 15 July 2008. Part numbers are subject to a change.

Table 2

New Part Numbers Serial Number Prefixes that Use the Part Numbers

319-0607 S/N:532, ; S/N:551, ; S/N:511, ; S/N:521, ; S/N:522, ; S/N:525, ; S/N:535, ; S/N:541, ; S/N:545, ; S/N:552, ; S/N:B3T, ; S/N:B9D, ; S/N:B9M, ; S/N:D9G

319-0674 S/N:C7D, ; S/N:C7P, ; S/N:C7Z, ; S/N:M7A

319-0675 S/N:HEP, ; S/N:BTM, ; S/N:CAP, ; S/N:CGZ, ; S/N:GAG, ; S/N:HAA, ; S/N:JAB, ; S/N:JCD, ; S/N:KDD, ; S/N:MCA, ; S/N:CYA, ; S/N:GKX, ; S/N:JNK, ; S/N:RBH, ; S/N:MKM, ; S/N:MSD, ; S/N:MSL, ; S/N:CEX, ; S/N:CEH, ; S/N:BCP, ; S/N:CLJ, ; S/N:AEM, ; S/N:AFM, ; S/N:BLE, ; S/N:BLT, ; S/N:BMK, ; S/N:BNL, ; S/N:BPM, ; S/N:BRJ, ; S/N:CAD, ; S/N:FDT, ; S/N:ACJ, ; S/N:ADE, ; S/N:BNC, ; S/N:BPP, ; S/N:BPZ, ; S/N:AAX, ; S/N:AGM, ; S/N:BMJ, ; S/N:BMY, ; S/N:BPS, ; S/N:BRZ, ; S/N:AEP, ; S/N:DAE, ; S/N:L5J, ; S/N:BRE

319-0676 S/N:101, ; S/N:102, ; S/N:103, ; S/N:104, ; S/N:125, ; S/N:202, ; S/N:301, ; S/N:302, ; S/N:AMZ, ; S/N:B1K, ; S/N:B2L, ; S/N:B3M, ; S/N:B4N, ; S/N:CAP, ; S/N:CBK, ; S/N:D3C, ; S/N:DKY

319-0677 S/N:ECH, ; S/N:AWN, ; S/N:CJX, ; S/N:JKR, ; S/N:JLS, ; S/N:JGK, ; S/N:BYE, ; S/N:T2D, ; S/N:DFP, ; S/N:SYM, ; S/N:JJG, ; S/N:LAB, ; S/N:EJC, ; S/N:KJR, ; S/N:PEH, ; S/N:CJM, ; S/N:GBR, ; S/N:KDG, ; S/N:KBE, ; S/N:DBH, ; S/N:SCR, ; S/N:GPB, ; S/N:PKE, ; S/N:C7K, ; S/N:C9M, ;

Have questions with 106871-3210?

Group cross 106871-3210 ZEXEL

Hino

106871-3210

220001306A

INJECTION-PUMP ASSEMBLY

EF700

EF700