Information injection-pump assembly

ZEXEL

106871-3180

1068713180

HINO

220001296A

220001296a

Rating:

Service parts 106871-3180 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1212

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106871-3180

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-3180

1068713180

HINO

220001296A

220001296a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4

3.9

4

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-6 deg. 90 89.5 90.5

Cal 1-6 deg. 90 89.5 90.5

Difference between angles 3

Cyl.1-2 deg. 135 134.5 135.5

Cyl.1-2 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-7 deg. 180 179.5 180.5

Cal 1-7 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-4 deg. 270 269.5 270.5

Cal 1-4 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-3 deg. 315 314.5 315.5

Cal 1-3 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.1

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

107.2

104.2

110.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

111

109

113

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

9.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

126.6

123.6

129.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.7

10.7

16.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

50

50

50

Average injection quantity

mm3/st.

122

112

132

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

950+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

1

0.5

1.5

Timer adjustment_03

Pump speed

r/min

1200

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

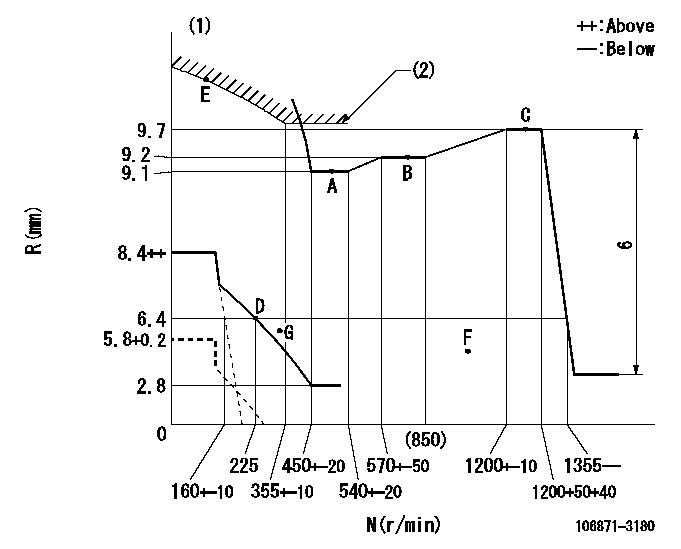

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Excess fuel setting for starting: SXL

----------

DL=5.4-0.2mm SXL=9.7+0.2mm

----------

----------

DL=5.4-0.2mm SXL=9.7+0.2mm

----------

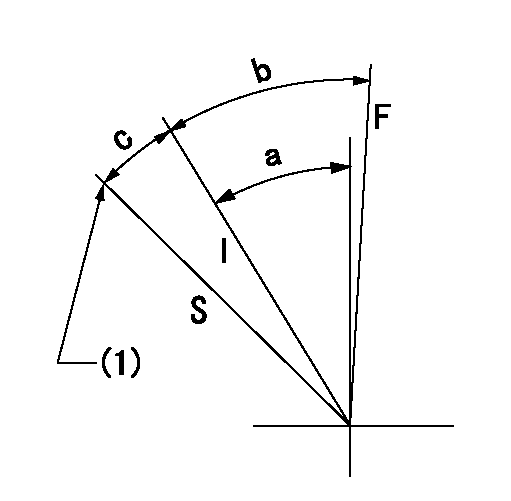

Speed control lever angle

F:Full speed

----------

----------

a=4deg+-5deg

----------

----------

a=4deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

(1)Rack position aa (pump speed bb r/min )

----------

aa=5.8+0.2mm bb=0r/min

----------

a=32deg+-5deg b=33deg+-3deg c=19deg+4deg-5deg

----------

aa=5.8+0.2mm bb=0r/min

----------

a=32deg+-5deg b=33deg+-3deg c=19deg+4deg-5deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325-25r/min Ra=6.4mm

----------

----------

N1=325-25r/min Ra=6.4mm

----------

Information:

Appendix

Configuration Information

Table 7

Over-Temp

Inlet Over-Temperature Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output function ON only during alarm

Assert Alarm Above

650 °C (1202 °F)

Hysteresis

20 °C (68 °F)

Upon Over Temperature extend alarm for 60 seconds

Table 8

Over-Pres

Over-Pressure Warning

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output Function ON only during alarm

Assert Alarm when the measured pressure exceeds 7" of Hg for 5% of the time during a 60 min measurement interval

Over-Pressure Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 2

Output Function Latched ON upon alarm

Assert alarm when the measured pressure exceeds 8" of Hg for 5% of the time during a 60 min measurement interval

Table 9

TC-Fail (1)

Open Thermocouple Detect

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Output During Alarm Output 1

Output Function Latched ON upon alarm

Assert alarm if measured temperature is above

1000 °C (1832 °F)

Shorted Thermocouple Detect

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Output During Alarm Output 1

Output Function Latched ON upon alarm

Assert alarm if pressure is greater than 1" of Hg for 10 min and measured temperature does not exceed

120 °C (248 °F)

( 1 ) Output selection applies to both open and shorted alarms

Table 10

Pressure Sensor Fail

No Change Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Outputs During Alarm Output 1

Output Function Latched ON upon Alarm

Assert alarm if exhaust temperature is above

250 °C (482 °F) for 10 min and the pressure doesn't change by at least 0.25" of Hg

Negative Pressure Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output Function Latched ON during alarm

Assert Alarm if temperature is above

200 °C (392 °F) for 10 min and the pressure is less than −1" of

Configuration Information

Table 7

Over-Temp

Inlet Over-Temperature Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output function ON only during alarm

Assert Alarm Above

650 °C (1202 °F)

Hysteresis

20 °C (68 °F)

Upon Over Temperature extend alarm for 60 seconds

Table 8

Over-Pres

Over-Pressure Warning

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output Function ON only during alarm

Assert Alarm when the measured pressure exceeds 7" of Hg for 5% of the time during a 60 min measurement interval

Over-Pressure Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 2

Output Function Latched ON upon alarm

Assert alarm when the measured pressure exceeds 8" of Hg for 5% of the time during a 60 min measurement interval

Table 9

TC-Fail (1)

Open Thermocouple Detect

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Output During Alarm Output 1

Output Function Latched ON upon alarm

Assert alarm if measured temperature is above

1000 °C (1832 °F)

Shorted Thermocouple Detect

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Output During Alarm Output 1

Output Function Latched ON upon alarm

Assert alarm if pressure is greater than 1" of Hg for 10 min and measured temperature does not exceed

120 °C (248 °F)

( 1 ) Output selection applies to both open and shorted alarms

Table 10

Pressure Sensor Fail

No Change Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Outputs During Alarm Output 1

Output Function Latched ON upon Alarm

Assert alarm if exhaust temperature is above

250 °C (482 °F) for 10 min and the pressure doesn't change by at least 0.25" of Hg

Negative Pressure Alarm

Condition Expected Value

Enable Alarm Yes

Log Alarm Transitions Yes

Active Output During Alarm Output 1

Output Function Latched ON during alarm

Assert Alarm if temperature is above

200 °C (392 °F) for 10 min and the pressure is less than −1" of