Information injection-pump assembly

BOSCH

F 019 Z10 027

f019z10027

ZEXEL

106871-2270

1068712270

MITSUBISHI

ME066309

me066309

Rating:

Service parts 106871-2270 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

31261-30020

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106871-2270

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 027

f019z10027

ZEXEL

106871-2270

1068712270

MITSUBISHI

ME066309

me066309

Zexel num

Bosch num

Firm num

Name

106871-2270

F 019 Z10 027

ME066309 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9 * K

8DC9 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1320

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.7

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

105

102

108

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.7+-0.5

Pump speed

r/min

200

200

200

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.7+-

0.5)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

105

104

106

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.7+-

0.5)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

116

111.4

120.6

Difference in delivery

mm3/st.

9.2

9.2

9.2

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

115

95

135

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

600+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

3.6

3.1

4.1

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

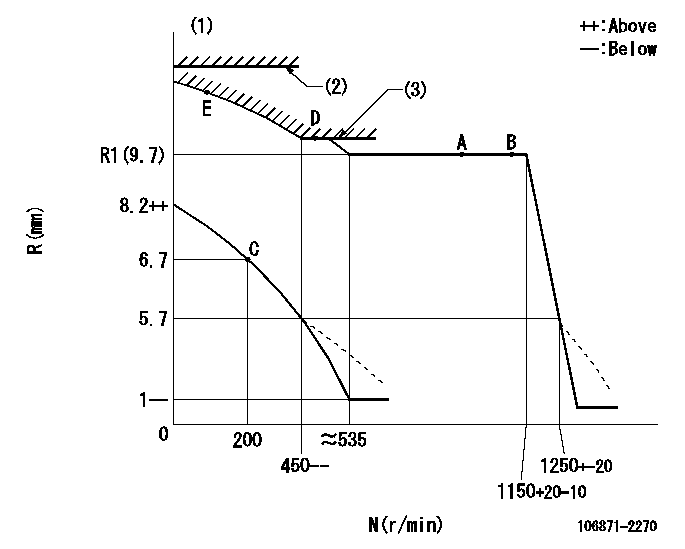

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Rack limit using the stop lever: R1

(3)Excess fuel setting for starting: SXL

----------

DL=5-0.2mm R1=12+0.2mm SXL=R1(9.7)+0.2mm

----------

----------

DL=5-0.2mm R1=12+0.2mm SXL=R1(9.7)+0.2mm

----------

0000000901

F:Full load

I:Idle

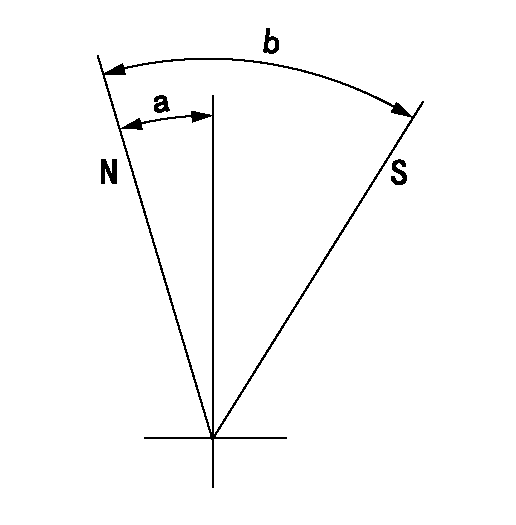

(1)Stopper bolt setting

----------

----------

a=0deg+-5deg b=17deg+-3deg

----------

----------

a=0deg+-5deg b=17deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=2deg+-5deg b=36deg+-5deg

----------

----------

a=2deg+-5deg b=36deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=6.3mm

----------

----------

N1=325+-5r/min Ra=6.3mm

----------

Information:

Table 2

Specifications for Valve Opening Pressure

Nozzle Assembly Valve Opening Pressure

1W-5829

10300 to 17690 kPa (1500 to 2505 psi)

4W-1819

4W-8483

7E-3969

7N-0449

7W-3710

7W-8043

9N-3979

101-0060

115-3354

122-9007

9L-7883

16560 to 17990 kPa (2400 to 2600 psi)

9L-9263

9N-2366

9L-6969

13090 to 19900 kPa (1900 2900 psi)

9N-3299

9N-3700 If the fuel nozzle is not within specifications, stop the test and do not use the nozzle.Check for Tip Leakage

Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Flush the fuel nozzle that is being tested by pumping the tester for 3 full strokes.

Open the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Use a clean cloth to dry the tip and the body of the fuel injector. All test fluid should be wiped from the nozzle assembly.

A clean cloth should be wrapped around the top of the fuel nozzle in order to absorb any internal return leakage.

Calculate the test pressure that will be used for the tip leakage test.Use the fuel nozzle's valve opening pressure, that has been previously recorded, in order to calculate the test pressure for the nozzle that is being tested.

Subtract a value of 1875 kPa (275 psi) from the valve opening pressure that was previously obtained.

Record the result of the calculation as the test pressure that will be used for the tip leakage test.

Slowly apply the test pressure, that has been calculated in Step 6, to the fuel nozzle.

Close the pump isolator valve.

Hold this test pressure for 10 seconds.

Count the number of drops of test fluid that drips from the nozzle during the duration of the test. Open the pump isolator valve in order to release the pressure on the fuel nozzle when the test is completed.Refer to the information that is provided in Table 3 in order to evaluate the results of the test.Note: Ensure that any test fluid that collects on the tip of the fuel nozzle is not fluid leakage from the test fixture.

Table 3

Specifications for Tip Leakage

(Leakage within 15 seconds after the test pressure is applied to the nozzle.)

Nozzle Assembly Maximum Leakage

1W-5829 20 drops (1)

4W-1819

4W-8483

7E-3969

7N-0449

7W-3710

7W-8043

9N-3979

101-0060

115-3354

122-9007

9L-7883 3 drops (1)

9L-9263

9N-2366

9L-6969 30 drops (1)

9N-3299

9N-3700

( 1 ) No minimum specificationIf the tip leakage for the fuel nozzle is not within specifications, stop the test and do not use the fuel nozzle.Test the Fuel Nozzle for Plugged Orifices

Illustration 2 g00923165

Spray patterns for pencil type fuel nozzles.

Close the gauge protector valve (0 to 40,000 kPa (0 to 5,800 psi) gauge).

Rapidly increase the pressure on the fuel nozzle until fluid sprays from the tip of the fuel nozzle.Note: For this test, each full

Have questions with 106871-2270?

Group cross 106871-2270 ZEXEL

Mitsubishi

Mitsubishi-Heav

Mitsubishi

106871-2270

F 019 Z10 027

ME066309

INJECTION-PUMP ASSEMBLY

8DC9

8DC9