Information injection-pump assembly

BOSCH

9 400 618 077

9400618077

ZEXEL

106871-1202

1068711202

ISUZU

1156032001

1156032001

Rating:

Service parts 106871-1202 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106871-1202

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 077

9400618077

ZEXEL

106871-1202

1068711202

ISUZU

1156032001

1156032001

Zexel num

Bosch num

Firm num

Name

106871-1202

9 400 618 077

1156032001 ISUZU

INJECTION-PUMP ASSEMBLY

K 14CD INJECTION PUMP ASSY PE8P PE

K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-3-

6-5-4-2

Pre-stroke

mm

5.5

5.47

5.53

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-3 deg. 135 134.75 135.25

Cal 1-3 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

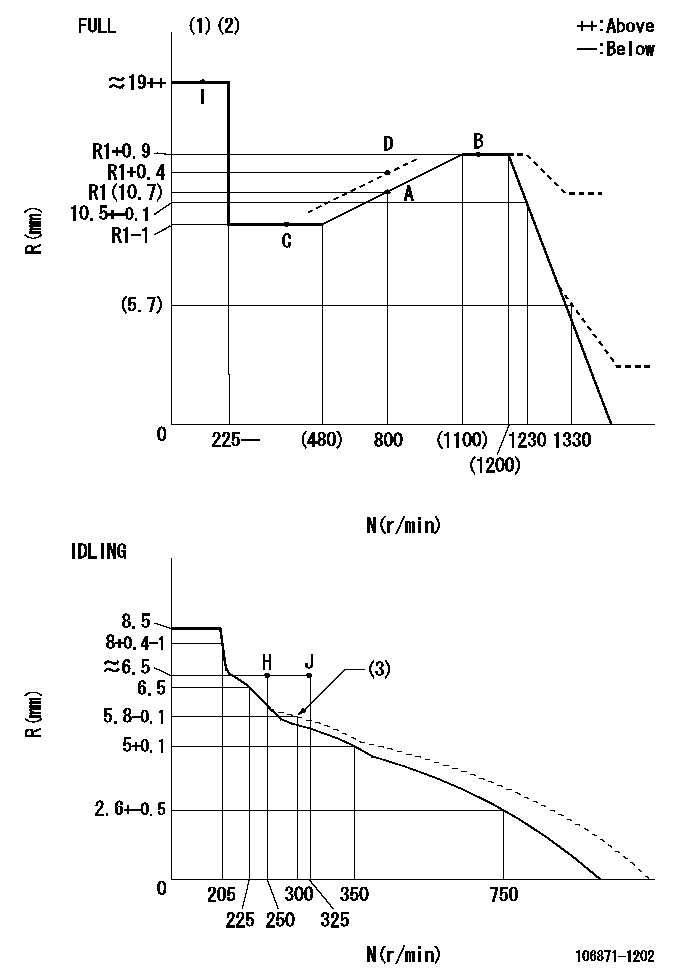

Injection quantity adjustment

Adjusting point

-

Rack position

10.7

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

121

119.4

122.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

6.5+-0.5

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

13.5

11.5

15.5

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.7)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

121

120

122

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

122

118

126

Fixing the lever

*

Timer adjustment

Pump speed

r/min

[N1+50]-

-

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

N1

Advance angle

deg.

0

0

0

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

2

1.5

2.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

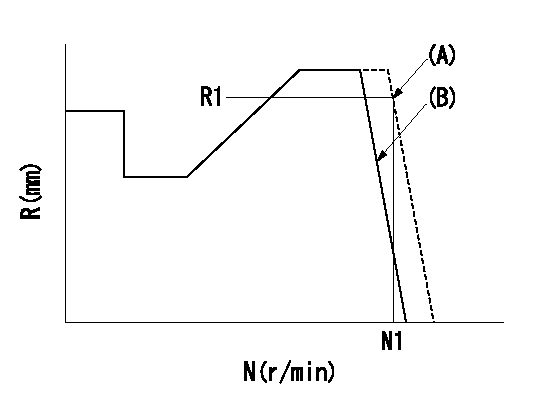

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AC89

----------

----------

T1=AC89

----------

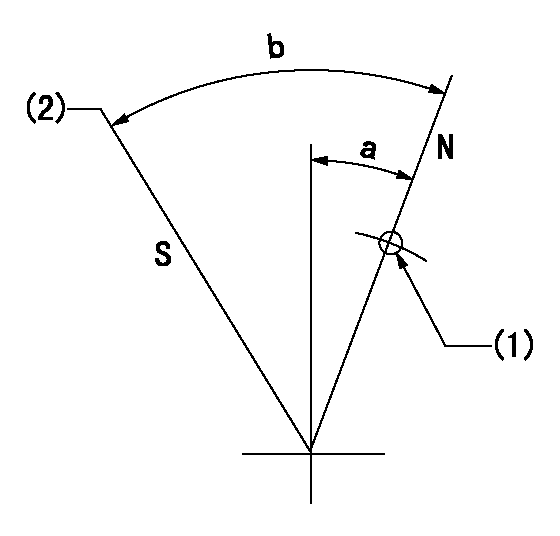

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt setting

----------

aa=55mm

----------

a=20deg+-5deg b=35deg+-3deg

----------

aa=55mm

----------

a=20deg+-5deg b=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=20deg+-5deg b=43deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=20deg+-5deg b=43deg+-5deg

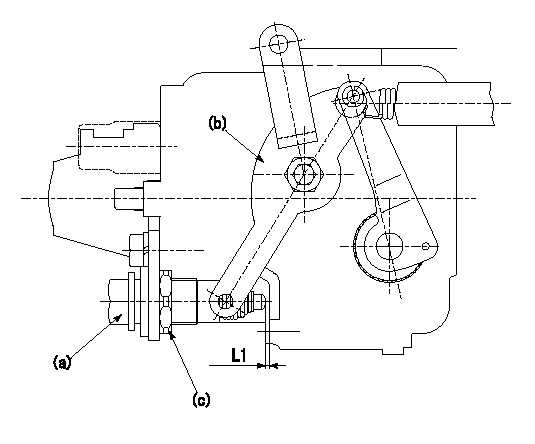

0000001501 AIR CYLINDER

(a) Air cylinder

(b) Speed lever

(c) Lock nut

1. Air cylinder adjustment procedure

(1)Fix the speed lever (b) at the idle side.

(2)Screw in the air cylinder (a)

(3)Set the clearance between the speed lever (b) and the air cylinder (a) to approximately L1.

----------

L1=1mm

----------

----------

L1=1mm

----------

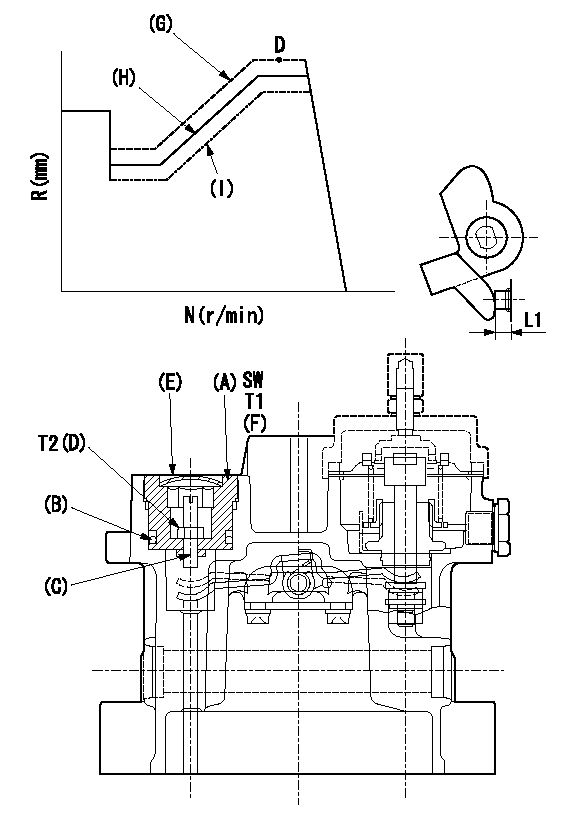

0000001601 TAMPER PROOF

SW:Inner hexagonal SW14

(F): Apply thread lock adhesive .

(G): Full tamper proof

(H): Full boost (Full rack)

(I): 0 boost

1. Mount (C) and (D) after adjusting the boost compensator.

2. Back off the load lever set screw L1 from the end face of the governor housing..

3. Apply boost pressure and set the full load at tamper set position point aa to obtain N1, Q1 and Ra using the screw C.

4. Fix using the nut (D).

5. Next, after adjusting the stop lever, confirm the point aa.

6. Reset the load lever to the full boost rack.

7. After completion of setting, seal using the plug (E).

----------

L1=6+1mm N1=800r/min Ra=R1(10.7)+0.4mm Q1=103+-1.6mm3/st aa=D

----------

T1=53.9~73.5N-m(5.5~7.5Kgf-m) T2=2.94~4.41N-m(0.3~0.45Kgf-m)

----------

L1=6+1mm N1=800r/min Ra=R1(10.7)+0.4mm Q1=103+-1.6mm3/st aa=D

----------

T1=53.9~73.5N-m(5.5~7.5Kgf-m) T2=2.94~4.41N-m(0.3~0.45Kgf-m)

0000001701 TAMPER PROOF

(A): Rotation tamper proof

(B): Full-speed setting

1. Back off the full-speed set bolt.

2. Confirm that the tamper setting position is N1, R1, Q1.

3. At that time, record the angle of the speed lever.

4. After confirming the above setting, set full speed.

----------

N1=(1420)r/min R1=5.7+-0.1mm Q1=-

----------

----------

N1=(1420)r/min R1=5.7+-0.1mm Q1=-

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(170deg)

----------

aa=10deg

----------

a=(170deg)

Information:

PARTS NEEDED

Qty

Part Number Description

1 4716029 MTG GP-INJECTOR (After Failure Only)

1 5548955 DEF SOFTWARE

1 ENGSOFTWARE ENGINE SOFTWARE

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 25% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

New DEF System software is available that reduces the risk of an internal DEF injector leak by improved temperature management. Please update the DEF system software at the next opportunity.

Ensure that all adjustments and repairs that are carried out to the Diesel Emission Fluid (DEF) system are performed by authorized personnel that have the correct training. Before beginning ANY work on the DEF system, refer to Operations and Maintenance Manual, "General Hazard" for safety information.

Before Failure:

Check that the engine software is the latest version before updating the DEF pump software.

If the engine software is not the latest version, update the Engine Software first.

If needed, update the engine software with the latest available in SIS WEB.

Flash the DEF Pump ECM with the software listed in the Parts Needed or latest available in SIS Web.

After Failure:

Ensure the appropriate steps have been followed when diagnosing a DEF injector failure. Refer to UENR0662.

If it is determined that replacement of DEF injector is required, refer to Disassembly and Assembly Manual - Diesel Fluid Injector - Remove and install.

After the DEF injector has been replaced, perform the DEF system software update as detailed in the "Before Failure" section above.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-5000 hrs,

0-60 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 0.5-hour job

An additional 1.5 hours is allowed for After failure.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 106871-1202?

Group cross 106871-1202 ZEXEL

Isuzu

Isuzu

106871-1202

9 400 618 077

1156032001

INJECTION-PUMP ASSEMBLY