Information injection-pump assembly

ZEXEL

106871-0960

1068710960

NISSAN-DIESEL

1671297507

1671297507

Rating:

Service parts 106871-0960 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97013

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106871-0960

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106871-0960

1068710960

NISSAN-DIESEL

1671297507

1671297507

Zexel num

Bosch num

Firm num

Name

106871-0960

1671297507 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RE8T * K

RE8T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

140.3

138.3

142.3

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

165.8

163.8

167.8

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.3

8.3

12.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

2.4

1.9

2.9

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

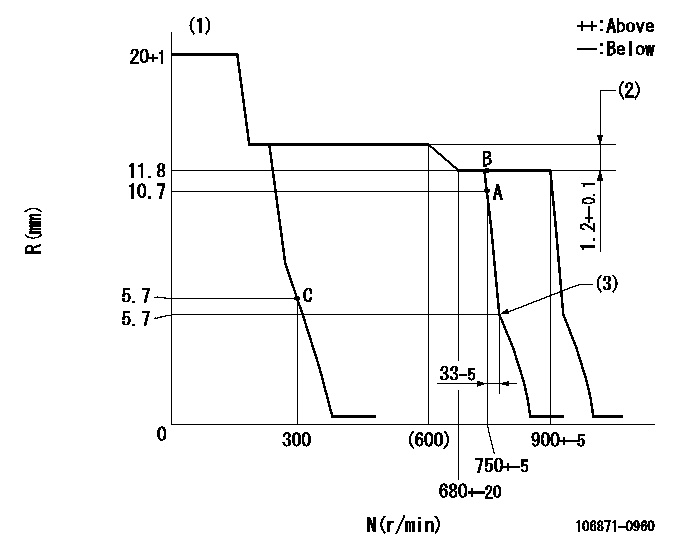

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

(3)Idle sub spring setting: L1.

----------

K=15 N1=750r/min N2=500r/min L1=5.7-0.3mm

----------

----------

K=15 N1=750r/min N2=500r/min L1=5.7-0.3mm

----------

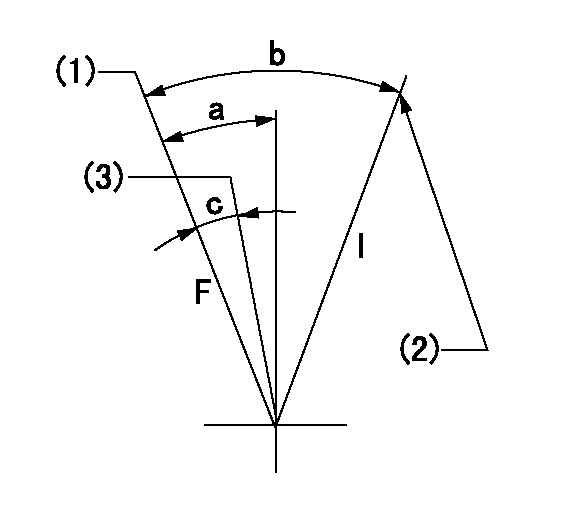

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Stopper bolt setting

(3)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=31deg+-5deg c=7deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=9deg+-5deg b=31deg+-5deg c=7deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

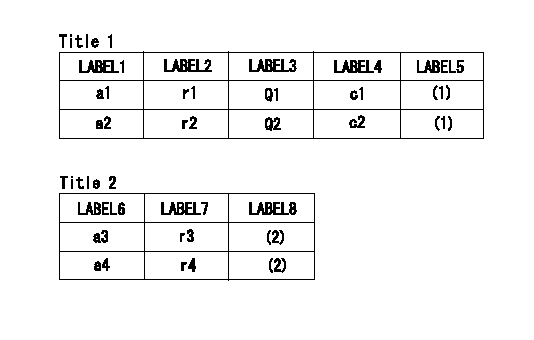

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=E a2=B r1=750r/min r2=750r/min Q1=165.8+-2mm3/st Q2=140.3+-2mm3/st c1=+-4% c2=+-4% a3=18 a4=15 r3=900r/min r4=750r/min

----------

----------

a1=E a2=B r1=750r/min r2=750r/min Q1=165.8+-2mm3/st Q2=140.3+-2mm3/st c1=+-4% c2=+-4% a3=18 a4=15 r3=900r/min r4=750r/min

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No. 8 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

9. Remove bracket assembly (16) and link (17). 10. Put identification marks on fuel racks (18) and (19), and remove the fuel racks. 11. Put identification marks on each spacer (20) and lifter (21) so they can be installed in their original position. 12. Remove fuel injection pump camshaft (22) from the pump housing.13. Remove O-ring seal (23). 14. Inspect link pivot shaft (24) and bracket locating pin (25). Make a replacement by removal of shaft (24) and dowel (25) with Tool (D). 15. Inspect upper bearing (26) and the lower bearing that hold the pinion gear in the pump housing.16. Make a replacement of bearings (26) if necessary.17. Inspect idler gear shaft (27). If a replacement is necessary, remove the shaft with Tooling (D). 18. Inspect fuel rack bearings (28) and camshaft bearings (29). If a replacement is necessary, remove bearings (28) and (29).19. Use Tooling (E) to remove bearings (28). 20. Remove regulator valve (30). 21. Remove pin (31) to disassemble the regulator valve, and inspect the components.22. Piston (32) must move freely in valve body (30).23. Make a reference to the Specifications for spring (34).24. Make a replacement of O-ring seals (33).Assemble Fuel Injection Pump Housing

Pin (2) must not extend out of either side of valve body (3).

1. Install spring (4), piston (1) and pin (2) in valve body (3).2. Put clean engine oil on the valve body and O-ring seals (5). Install the oil bypass valve in the pump housing. Tighten the bypass valve body to a torque of 68 14 N m (50 10 lb ft). 3. Install the camshaft front and rear bearings with Tooling (A). Install the front bearing until it is a distance of 1.0 0.5 mm (.04 .02 in) from the front surface of the pump housing. Make sure both oil holes in bearing are in alignment with the oil holes in the pump housing. 4. Put Tool (B) in the fuel pump housing with the dowels of Tool (B) in alignment with the left fuel rack bore. Install the bolt that holds the tool in place on the housing.5. Put a new bearing in position with the tab of the bearing up. Install the bearing with Tool (C) until the shoulder of Tool (C) makes contact with Tool (B).6. Turn Tool (B), and make an alignment of the dowels on Tool (B) with the right fuel rack bore.7. Do Step 3 again for the left fuel rack bearing. 8. Install shaft (6) to a height of 16.8 0.5 mm (.66 .02 in). 9. Make sure the chamfer on the lower bearing for the pinion gear is toward the inside and the notch is in the location shown. Install the bearing 28.4 0.5 mm (1.12 .02 in) below the bearing bore surface with Tooling (D).10. Make sure the chamfer on the upper bearing for the pinion gear is toward the inside and the notch is in the location shown. Use

Pin (2) must not extend out of either side of valve body (3).

1. Install spring (4), piston (1) and pin (2) in valve body (3).2. Put clean engine oil on the valve body and O-ring seals (5). Install the oil bypass valve in the pump housing. Tighten the bypass valve body to a torque of 68 14 N m (50 10 lb ft). 3. Install the camshaft front and rear bearings with Tooling (A). Install the front bearing until it is a distance of 1.0 0.5 mm (.04 .02 in) from the front surface of the pump housing. Make sure both oil holes in bearing are in alignment with the oil holes in the pump housing. 4. Put Tool (B) in the fuel pump housing with the dowels of Tool (B) in alignment with the left fuel rack bore. Install the bolt that holds the tool in place on the housing.5. Put a new bearing in position with the tab of the bearing up. Install the bearing with Tool (C) until the shoulder of Tool (C) makes contact with Tool (B).6. Turn Tool (B), and make an alignment of the dowels on Tool (B) with the right fuel rack bore.7. Do Step 3 again for the left fuel rack bearing. 8. Install shaft (6) to a height of 16.8 0.5 mm (.66 .02 in). 9. Make sure the chamfer on the lower bearing for the pinion gear is toward the inside and the notch is in the location shown. Install the bearing 28.4 0.5 mm (1.12 .02 in) below the bearing bore surface with Tooling (D).10. Make sure the chamfer on the upper bearing for the pinion gear is toward the inside and the notch is in the location shown. Use

Have questions with 106871-0960?

Group cross 106871-0960 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106871-0960

1671297507

INJECTION-PUMP ASSEMBLY

RE8T

RE8T