Information injection-pump assembly

ZEXEL

106871-0560

1068710560

Rating:

Cross reference number

ZEXEL

106871-0560

1068710560

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

106.5

105.5

107.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.6+-0.5

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

105.6

103.6

107.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

F

Rack position

6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

11.5

9.5

13.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

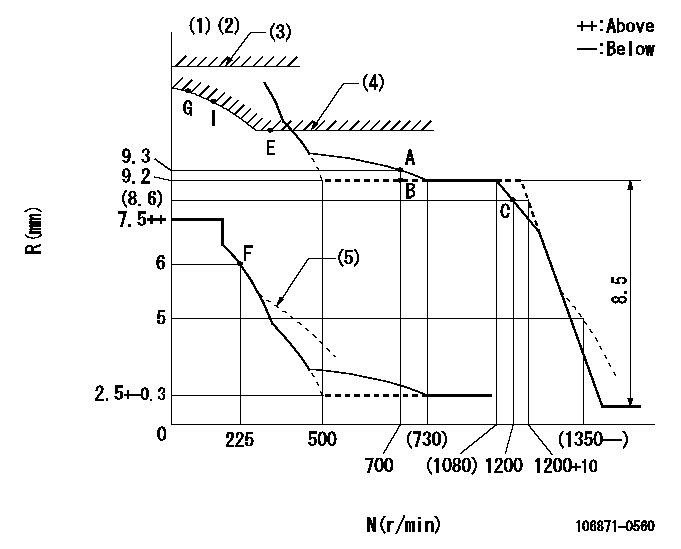

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Rack limit using the stop lever: R1

(4)Excess fuel setting for starting: SXL

(5)Damper spring setting: DL

----------

RT=1 TH=2.2mm R1=13.8+0.2mm SXL=10.1+-0.1mm DL=5.6-0.2mm

----------

----------

RT=1 TH=2.2mm R1=13.8+0.2mm SXL=10.1+-0.1mm DL=5.6-0.2mm

----------

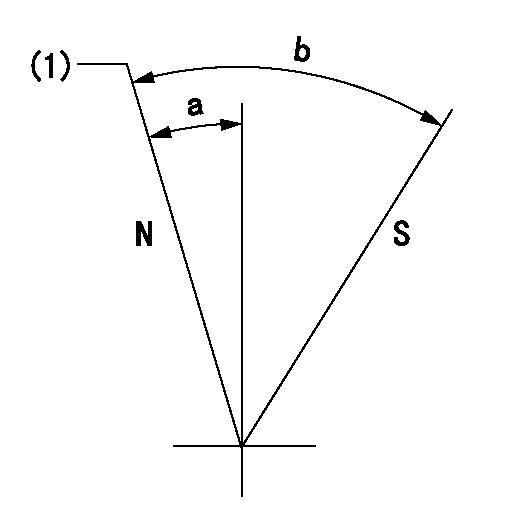

Speed control lever angle

F:Full speed

----------

----------

a=0deg+-5deg

----------

----------

a=0deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=25.5deg+-3deg

----------

----------

a=24.5deg+-5deg b=25.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

----------

aa=13.8+0.2mm

----------

a=10.5deg+-5deg b=36deg+-5deg

----------

aa=13.8+0.2mm

----------

a=10.5deg+-5deg b=36deg+-5deg

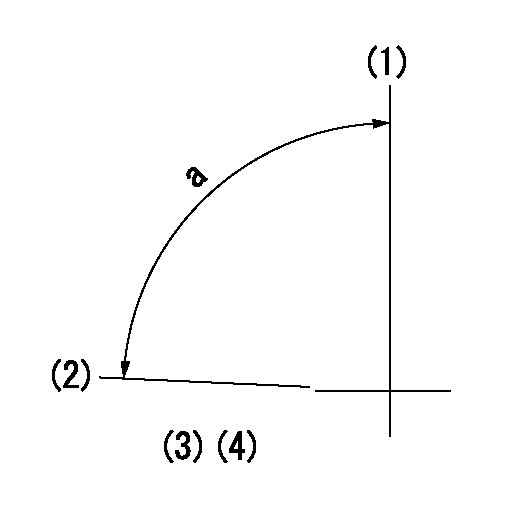

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

Warning Operation

Two flashing warning lamps and an alarm inform the operator that: * An ether cylinder is empty.* Both ether cylinders are empty.* A noncritical fault is present.* A critical fault is present.The warning lamps and alarm can be tested by placing the ether system switch in the Test/Disable position. The warning alarm will turn ON for two seconds and the warning lamps will remain ON continuously until the switch is returned to the Auto position. If a solenoid valve is shorted to +BAT, the alarm sounds whenever the key switch is in the RUN or START position. The alarm beeps at the rate of approximately 1.3 seconds ON and 2.0 seconds OFF. The engine could be damaged if ether was injected before the engine is cranked.An Ether Cylinder Is Empty

One of the two warning lamps inform the operator when an ether cylinder is empty. The lamp flashes at the rate of 1.5 Hz (flashes per second) with equal ON and OFF times. The lamps and ether solenoid assemblies are correspondingly marked 1 and 2. When empty ether cylinder warning lamp 1 is flashing, ether cylinder 1 needs replaced. When empty ether cylinder warning lamp 2 is flashing, ether cylinder 2 needs replaced. (On 3516 engines, both ether cylinders of the set need replaced.) The lamps stop flashing when the reset switch is activated during ether cylinder replacement. The empty ether cylinder warning lamp will also flash if there is no ether cylinder installed.Both Ether Cylinders Are Empty

When both ether cylinders are empty (on 3516 engines, both ether cylinder sets), both empty ether cylinder warning lamps and the alarm are activated. Empty ether cylinder warning lamps 1 and 2 flash at the same time, at the rate of 1.5 Hz (flashes per second). The alarm also sounds, during the ether injection time, approximately 1.3 seconds ON and 2.0 seconds OFF.A Noncritical Fault Is Present

When a noncritical fault is present, both empty ether cylinder warning lamps are activated. Empty ether cylinder warning lamps 1 and 2 flash alternately (taking turns ON and OFF) at the rate of 3.0 Hz (flashes per second). The system continues to operate during a noncritical fault.A Critical Fault Is Present

When a critical fault is present. both empty ether cylinder warning lamps and the alarm are activated. Empty ether cylinder warning lamps 1 and 2 flash alternately (taking turns ON and OFF) at the rate of 3.0 Hz (flashes per second). The alarm also sounds, during the ether injection time, approximately 1.3 seconds ON and 2.0 seconds OFF. If possible, ether injections are disabled during a critical fault.Diagnostic Operation

Ether Injection Control DiagnosticsThe ether injection control has diagnostic capabilities to assist in troubleshooting. The control detects and records faults that occur to the system. During a critical fault, if possible, the control disables ether injection. During a noncritical fault, the control takes alternate action so that the system continues to function.The diagnostic display, on the ether injection control, displays a code which represents the fault that

Two flashing warning lamps and an alarm inform the operator that: * An ether cylinder is empty.* Both ether cylinders are empty.* A noncritical fault is present.* A critical fault is present.The warning lamps and alarm can be tested by placing the ether system switch in the Test/Disable position. The warning alarm will turn ON for two seconds and the warning lamps will remain ON continuously until the switch is returned to the Auto position. If a solenoid valve is shorted to +BAT, the alarm sounds whenever the key switch is in the RUN or START position. The alarm beeps at the rate of approximately 1.3 seconds ON and 2.0 seconds OFF. The engine could be damaged if ether was injected before the engine is cranked.An Ether Cylinder Is Empty

One of the two warning lamps inform the operator when an ether cylinder is empty. The lamp flashes at the rate of 1.5 Hz (flashes per second) with equal ON and OFF times. The lamps and ether solenoid assemblies are correspondingly marked 1 and 2. When empty ether cylinder warning lamp 1 is flashing, ether cylinder 1 needs replaced. When empty ether cylinder warning lamp 2 is flashing, ether cylinder 2 needs replaced. (On 3516 engines, both ether cylinders of the set need replaced.) The lamps stop flashing when the reset switch is activated during ether cylinder replacement. The empty ether cylinder warning lamp will also flash if there is no ether cylinder installed.Both Ether Cylinders Are Empty

When both ether cylinders are empty (on 3516 engines, both ether cylinder sets), both empty ether cylinder warning lamps and the alarm are activated. Empty ether cylinder warning lamps 1 and 2 flash at the same time, at the rate of 1.5 Hz (flashes per second). The alarm also sounds, during the ether injection time, approximately 1.3 seconds ON and 2.0 seconds OFF.A Noncritical Fault Is Present

When a noncritical fault is present, both empty ether cylinder warning lamps are activated. Empty ether cylinder warning lamps 1 and 2 flash alternately (taking turns ON and OFF) at the rate of 3.0 Hz (flashes per second). The system continues to operate during a noncritical fault.A Critical Fault Is Present

When a critical fault is present. both empty ether cylinder warning lamps and the alarm are activated. Empty ether cylinder warning lamps 1 and 2 flash alternately (taking turns ON and OFF) at the rate of 3.0 Hz (flashes per second). The alarm also sounds, during the ether injection time, approximately 1.3 seconds ON and 2.0 seconds OFF. If possible, ether injections are disabled during a critical fault.Diagnostic Operation

Ether Injection Control DiagnosticsThe ether injection control has diagnostic capabilities to assist in troubleshooting. The control detects and records faults that occur to the system. During a critical fault, if possible, the control disables ether injection. During a noncritical fault, the control takes alternate action so that the system continues to function.The diagnostic display, on the ether injection control, displays a code which represents the fault that