Information injection-pump assembly

BOSCH

9 400 618 030

9400618030

ZEXEL

106871-0512

1068710512

NISSAN-DIESEL

1671397669

1671397669

Rating:

Cross reference number

BOSCH

9 400 618 030

9400618030

ZEXEL

106871-0512

1068710512

NISSAN-DIESEL

1671397669

1671397669

Zexel num

Bosch num

Firm num

Name

106871-0512

9 400 618 030

1671397669 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RE8 * K

RE8 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

105.2

104.2

106.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

12.9

10.9

14.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

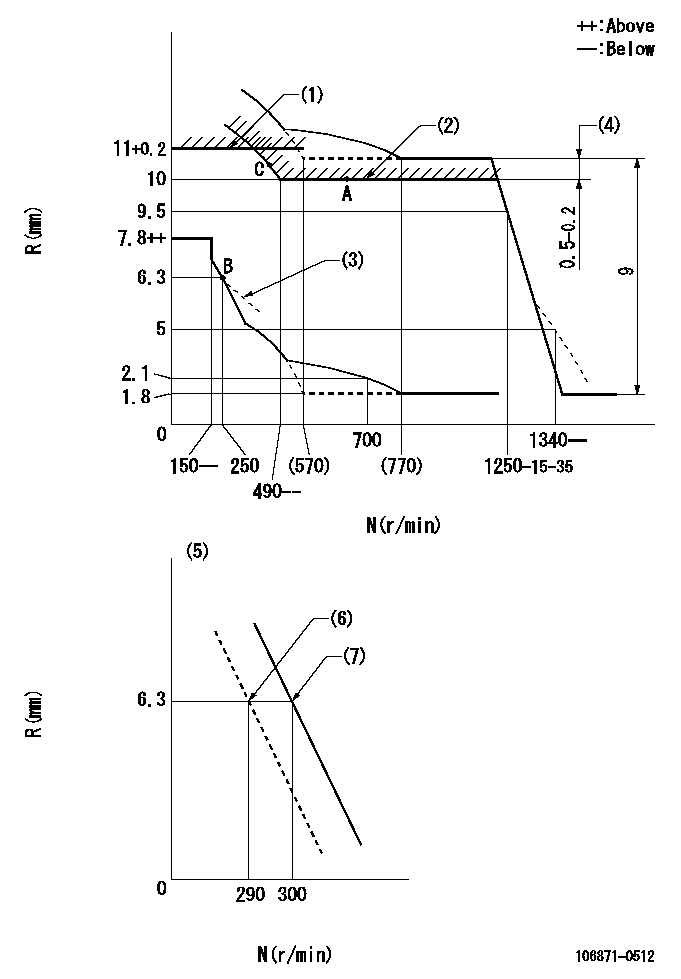

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack limit using stop lever: R1 (at N = N1 or less).

(2)Excess fuel setting for starting

(3)Damper spring setting: DL

(4)At pump speed N2

(5)Variable speed specification: idling adjustment

(6)Main spring setting

(7)Set idle sub-spring

----------

N1=100r/min DL=6.3-0.2mm N2=1100r/min

----------

----------

N1=100r/min DL=6.3-0.2mm N2=1100r/min

----------

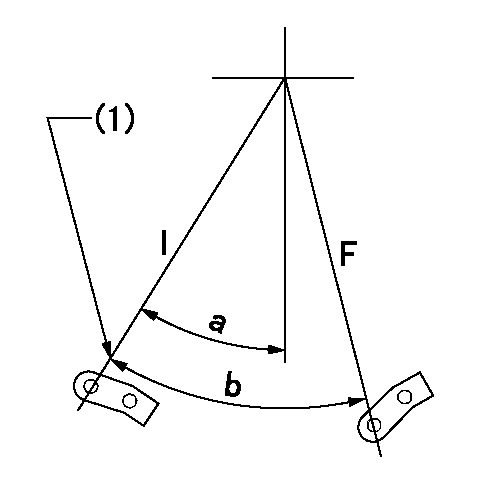

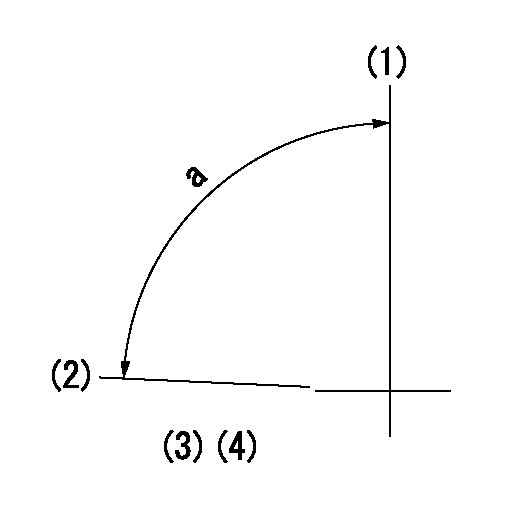

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Set the stopper bolt (fixed at full-load position at delivery.)

----------

----------

a=(24deg)+-5deg b=(12deg)+-5deg

----------

----------

a=(24deg)+-5deg b=(12deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=31deg+-3deg

----------

----------

a=24.5deg+-5deg b=31deg+-3deg

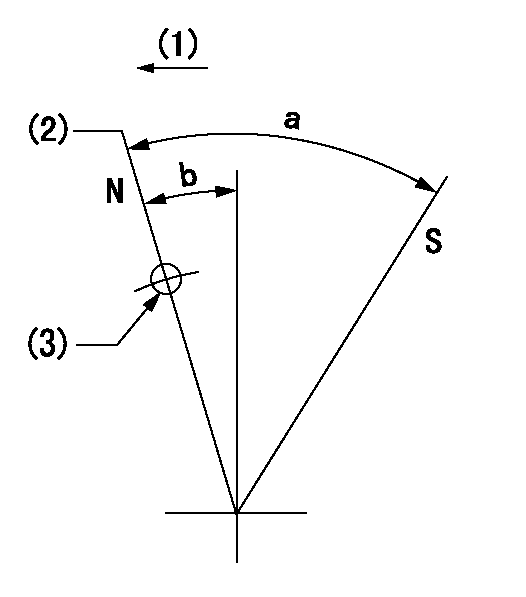

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

(2)Rack position = aa

(3)Use the hole at R = bb

----------

aa=11+0.2mm bb=32mm

----------

a=28.5deg+-5deg b=3deg+-5deg

----------

aa=11+0.2mm bb=32mm

----------

a=28.5deg+-5deg b=3deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

If the crankshaft is not in the correct position when the magnetic pickup sensor is installed, the magnetic probe will be damaged when the engine is started.

F. Put a 2D6392 O-Ring Seal on the end of the Magnetic Pick-up Sensor (a small amount of clean engine oil will let the seal slide onto the sensor more easily).G. Push the sensor through the adapter until it comes in contact with the counterweight and move the O-Ring Seal down against the adapter.H. Withdraw the sensor 1 mm (.04 in.) and hand tighten the nut on the adapter sleeve to firmly hold the timing probe in position.I. Connect cable for magnetic pick-up to the magnetic pick-up sensor. Step 2. Install ECAP And Injector HarnessA. Connect an ECAP to the Engine Data Link Connector (J8).B. Install the Injection "T" Harness on the Fuel Injector Connector (J5/P5) in the valve cover base.C. Be certain all connections (probe, harness, ECAP) are made correctly. Use special care when connecting "T" Harness to J5. The plug can be mis-aligned. Also use care when reconnecting J5 and P5. Incorrect installation will result in a "No Start" condition. Step 3. Calibrate Speed/Timing SensorA. Start the engine and run at low idle until the engine has warmed up enough to change out of Cold Mode operation. The "Diagnostic Lamp" should go out after the engine has started and the 10 second lamp test is complete. The engine rpm will decrease from approximately 1000 rpm while in the cold mode to the programmed low idle rpm when out of Cold Mode.B. Check for ACTIVE Diagnostic Codes. Use the procedures in this manual to troubleshoot and repair any ACTIVE Diagnostic Codes before attempting a calibration check.C. After engine has shifted out of Cold Mode, select the 3176 Timing Calibrate Screen on the ECAP. To insure the most accurate timing calibration, the engine rpm should be held as steady as possible at approximately 1500 rpm. This can be performed using the hand throttle. Any major changes (greater than 100 rpm) will slow down the procedure and make it less accurate.D. Press on the "space" key on the ECAP and wait until the ECAP indicates timing is CALIBRATED (approximately 15 seconds).E. Verify that timing has been calibrated by observing the "Desired Timing" bar display on the ECAP. Run the engine at different rpm's, allowing a few seconds at each setting for the rpm to stabilize. * If the ECAP display reads that injection timing is CALIBRATED, but during verification, the actual timing bar display is not within the two vertical timing tolerance lines and/or the display is erratic, repeat the timing calibration procedure.* If the ECAP display reads UNABLE TO CALIBRATE TIMING, the electronic injection timing has NOT been set. OK: Timing is functional and calibrated if the right end of the bar graph display stays within the vertical bars at all steady speeds. NOT OK: Recheck the tool installation and tool operation. Verify that the engine speeds were kept stable ( 50

Have questions with 106871-0512?

Group cross 106871-0512 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106871-0512

9 400 618 030

1671397669

INJECTION-PUMP ASSEMBLY

RE8

RE8