Information injection-pump assembly

ZEXEL

106871-0420

1068710420

Rating:

Cross reference number

ZEXEL

106871-0420

1068710420

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

132.4

131.4

133.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.6

11.6

15.6

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.8+0.2

Pump speed

r/min

40

40

40

Average injection quantity

mm3/st.

115

105

125

Fixing the lever

*

Rack limit

*

Test data Ex:

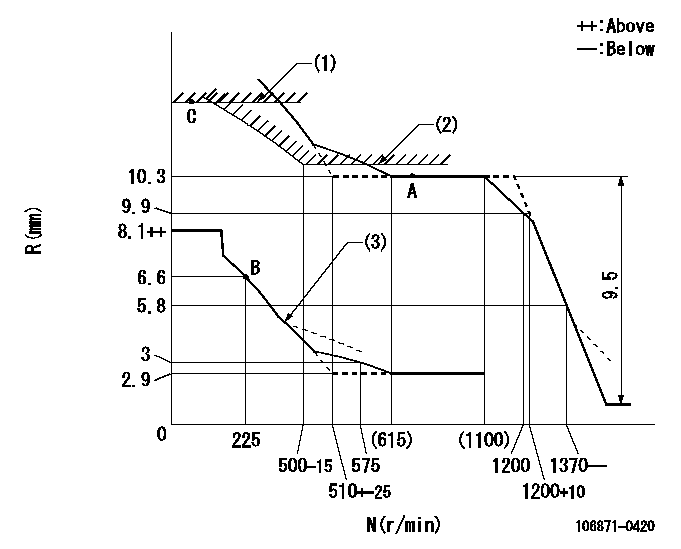

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Rack limit using the stop lever: R1

(2)Excess fuel setting for starting: SXL

(3)Damper spring setting: DL

----------

R1=11.8+0.2mm SXL=10.3+0.2mm DL=5.6-0.2mm

----------

----------

R1=11.8+0.2mm SXL=10.3+0.2mm DL=5.6-0.2mm

----------

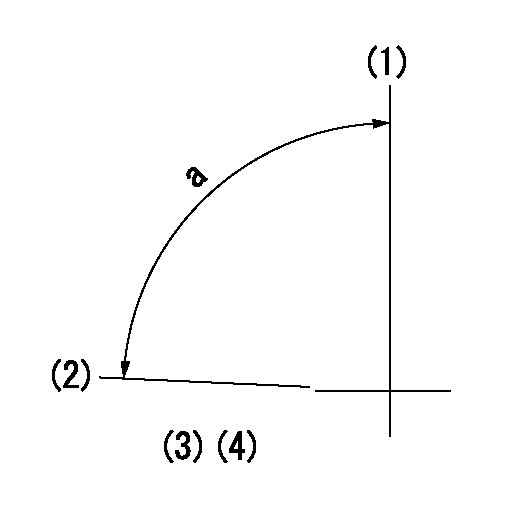

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1250++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

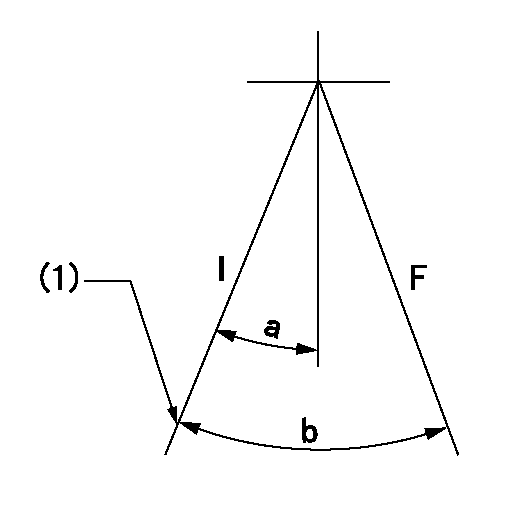

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=27.5deg+-3deg

----------

----------

a=24.5deg+-5deg b=27.5deg+-3deg

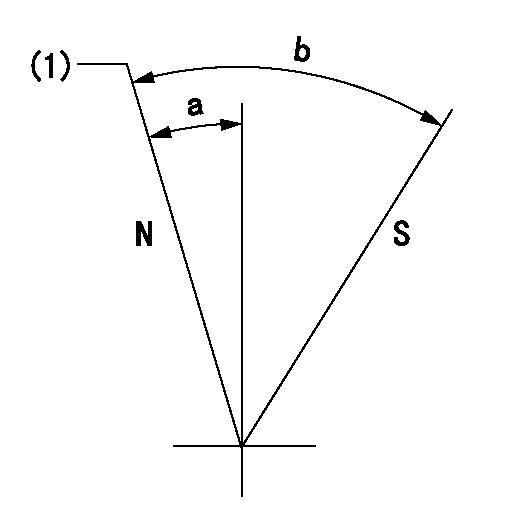

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

----------

aa=11.8+0.2mm

----------

a=1.5deg+-5deg b=30.5deg+-5deg

----------

aa=11.8+0.2mm

----------

a=1.5deg+-5deg b=30.5deg+-5deg

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=650r/min Ra=10.3mm

----------

----------

N1=650r/min Ra=10.3mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the beginning of injection of the No. 8 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

3306 New Scroll Fuel System (NSFS) Hydraulic Actuator

The variable power actuator is mounted to the rear of the governor housing, where the shutoff solenoid is normally mounted. The actuator rod may be in one of two positions -- extended or retracted. The extended position limits the fuel rack travel to the lower power fuel setting. The retracted position allows the fuel rack to travel to the higher power fuel setting. By limiting the travel of the fuel rack, the fuel being injected into the engine is controlled. Fuel being injected into the engine determines the output power of the engine. The position of the actuator rod is determined by the gear engaged in the transmission of the applicable vehicle.High Power Range

Typical Variable Power Arrangement

1. Manifold. 2. Solenoid control valve. 3. Variable power actuator. 4. Governor control lever. 5. Transmission. 6. Switch.An electric switch (6) is mounted in the transmission (5). The transmission (5) is shifted into a gear where the higher power range is allowed. A transmission interlock pin causes the normally open switch (6) to close. When switch (6) is closed, it energizes solenoid control valve (2). The energized solenoid control valve (2) allows engine lube oil (under normal engine lube oil pressure) to flow through manifold (1) and into actuator (3).

Governor And Actuator

3. Actuator. 7. Oil inlet/outlet port. 11. Governor servo valve. 12. Lever. 13. Governor control shaft. 14. Actuator rod.The engine oil coming in port (7) compresses spring (15) and moves actuator rod (14) to the RETRACTED position. The RETRACTED actuator rod (14) allows the fuel rack more travel in the FUEL ON direction by a mechanical linkage through the governor servo valve (11) and lever (12). The fuel rack travel is now limited by the fuel setting screw.The actuator rod (14) will remain in the RETRACTED position as long as solenoid control valve (2) is energized. A light on the operator's console indicates when the engine is operating in the higher power range.

Governor And Variable Power Actuator (Retracted Position7. Oil inlet/outlet port.8. Washered adjusting

The variable power actuator is mounted to the rear of the governor housing, where the shutoff solenoid is normally mounted. The actuator rod may be in one of two positions -- extended or retracted. The extended position limits the fuel rack travel to the lower power fuel setting. The retracted position allows the fuel rack to travel to the higher power fuel setting. By limiting the travel of the fuel rack, the fuel being injected into the engine is controlled. Fuel being injected into the engine determines the output power of the engine. The position of the actuator rod is determined by the gear engaged in the transmission of the applicable vehicle.High Power Range

Typical Variable Power Arrangement

1. Manifold. 2. Solenoid control valve. 3. Variable power actuator. 4. Governor control lever. 5. Transmission. 6. Switch.An electric switch (6) is mounted in the transmission (5). The transmission (5) is shifted into a gear where the higher power range is allowed. A transmission interlock pin causes the normally open switch (6) to close. When switch (6) is closed, it energizes solenoid control valve (2). The energized solenoid control valve (2) allows engine lube oil (under normal engine lube oil pressure) to flow through manifold (1) and into actuator (3).

Governor And Actuator

3. Actuator. 7. Oil inlet/outlet port. 11. Governor servo valve. 12. Lever. 13. Governor control shaft. 14. Actuator rod.The engine oil coming in port (7) compresses spring (15) and moves actuator rod (14) to the RETRACTED position. The RETRACTED actuator rod (14) allows the fuel rack more travel in the FUEL ON direction by a mechanical linkage through the governor servo valve (11) and lever (12). The fuel rack travel is now limited by the fuel setting screw.The actuator rod (14) will remain in the RETRACTED position as long as solenoid control valve (2) is energized. A light on the operator's console indicates when the engine is operating in the higher power range.

Governor And Variable Power Actuator (Retracted Position7. Oil inlet/outlet port.8. Washered adjusting