Information injection-pump assembly

BOSCH

9 400 618 018

9400618018

ZEXEL

106871-0322

1068710322

NISSAN-DIESEL

1671397616

1671397616

Rating:

Cross reference number

BOSCH

9 400 618 018

9400618018

ZEXEL

106871-0322

1068710322

NISSAN-DIESEL

1671397616

1671397616

Zexel num

Bosch num

Firm num

Name

106871-0322

9 400 618 018

1671397616 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RD8T K 14CD INJECTION PUMP ASSY PE8P PE

RD8T K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

127

126

128

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.4

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

120

118

122

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.9+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

86

84

88

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

12.8

11.7

13.9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

300+100

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

3.4

2.9

3.9

Timer adjustment_04

Pump speed

r/min

1250+50

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

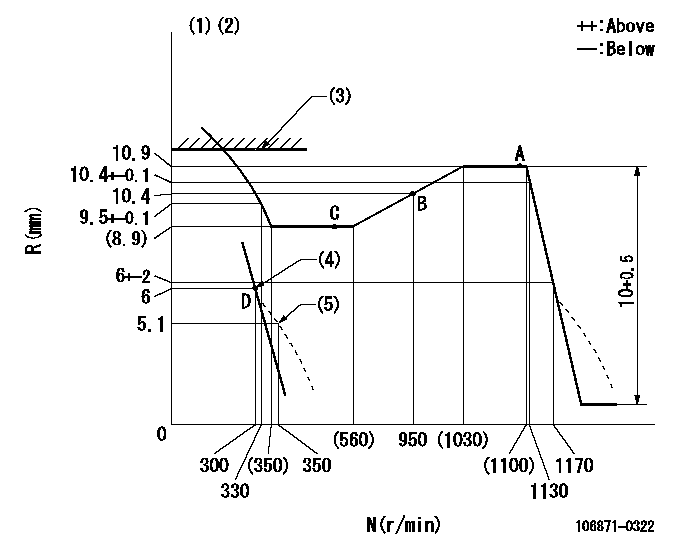

Governor adjustment

N:Pump speed

R:Rack position (mm)

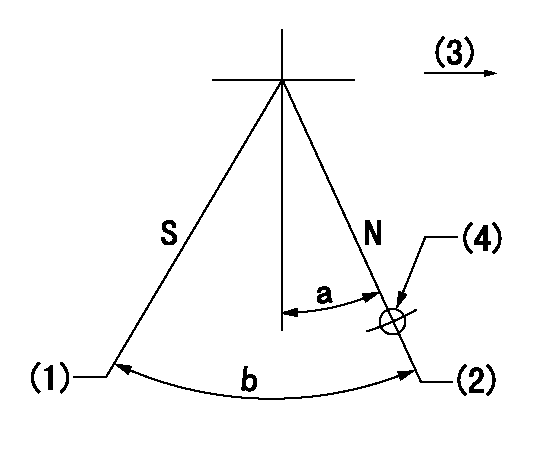

(1)Variable speed specification.

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Rack limit using stop lever: R1 (at N = N1)

(4)Main spring setting

(5)Damper spring setting

----------

R1=12.3+-0.1mm N1=0r/min

----------

----------

R1=12.3+-0.1mm N1=0r/min

----------

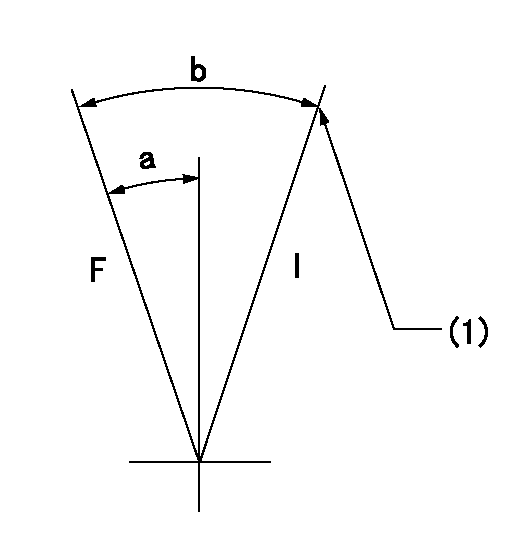

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=19deg+-5deg

----------

----------

a=6deg+-5deg b=19deg+-5deg

0000000901

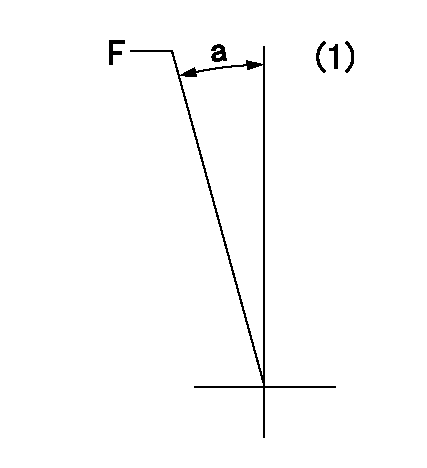

F:Full load

(1)Fix the lever at the full load position

----------

----------

a=5deg+-5deg

----------

----------

a=5deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

(3)Drive side

(4)Use the hole above R = cc

----------

aa=1+0.5mm bb=12.3+-0.1mm cc=32mm

----------

a=6deg+-5deg b=31.5deg+-3deg

----------

aa=1+0.5mm bb=12.3+-0.1mm cc=32mm

----------

a=6deg+-5deg b=31.5deg+-3deg

Information:

1W4563, 1W5634 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 270 25 N m (200 20 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.2P9642 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 149 7 N m (110 5 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 270 25 N m (200 20 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.2P9642 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 149 7 N m (110 5 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.

Have questions with 106871-0322?

Group cross 106871-0322 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106871-0322

9 400 618 018

1671397616

INJECTION-PUMP ASSEMBLY

RD8T

RD8T