Information injection-pump assembly

ZEXEL

106871-0000

1068710000

Rating:

Cross reference number

ZEXEL

106871-0000

1068710000

Zexel num

Bosch num

Firm num

Name

106871-0000

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105101-4760

Nozzle

105015-3440

Bosch type code

DLLA142S394NP66

Nozzle holder

105031-4210

Opening pressure

MPa

22.6

Opening pressure

kgf/cm2

230

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2.2-1010

Outer diameter - inner diameter - length (mm) mm 6-2.2-1010

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.26

1.94

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

116

114

118

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

135

133

137

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.3

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

123

120

126

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_04

Adjusting point

D

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

20

18

22

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.6

Boost pressure

kPa

16

9.3

22.7

Boost pressure

mmHg

120

70

170

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

11.3

Boost pressure

kPa

30

28.7

31.3

Boost pressure

mmHg

225

215

235

Timer adjustment

Pump speed

r/min

300+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

3.4

2.9

3.9

Timer adjustment_04

Pump speed

r/min

1250+50

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

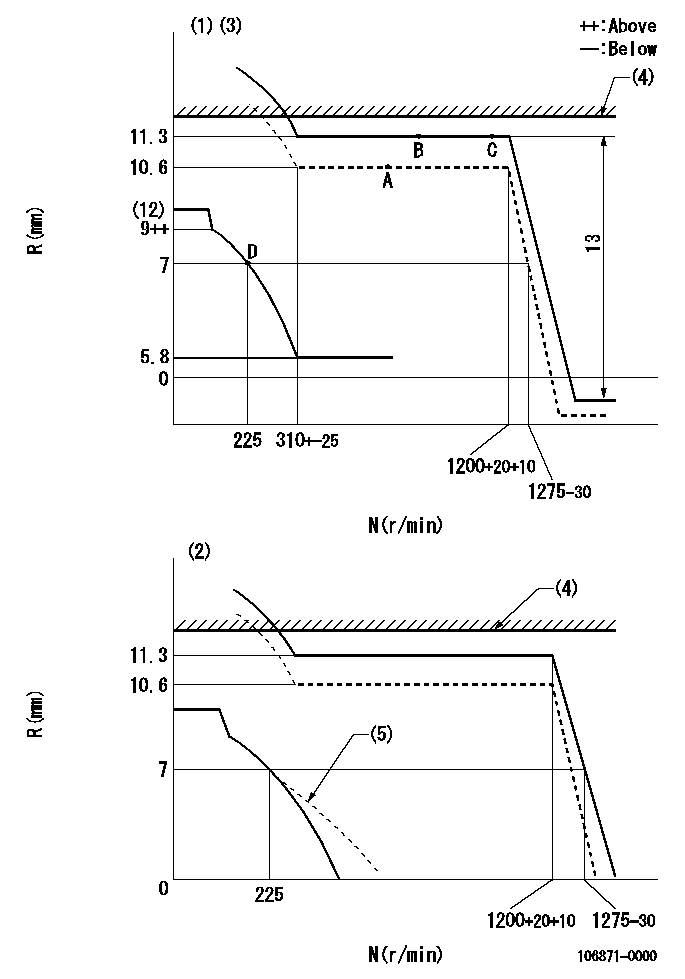

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Speed control lever full position

(2)Load control lever's full position

(3)Target notch: K

(4)RACK LIMIT: RAL

(5)Damper spring setting: DL

----------

K=5 RAL=11.7+-0.1mm DL=7-0.2mm

----------

----------

K=5 RAL=11.7+-0.1mm DL=7-0.2mm

----------

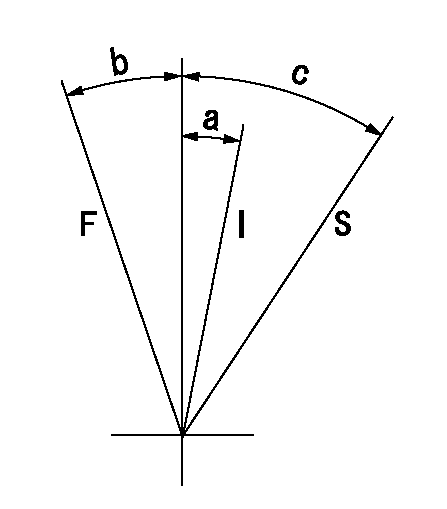

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=21deg+-5deg b=10.5deg+-5deg c=32deg+-3deg

----------

----------

a=21deg+-5deg b=10.5deg+-5deg c=32deg+-3deg

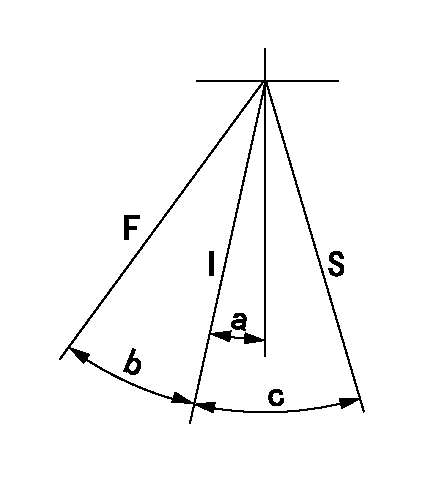

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=5deg+-5deg b=12deg+-3deg c=13.5deg+-3deg

----------

----------

a=5deg+-5deg b=12deg+-3deg c=13.5deg+-3deg

Information:

Stopping the engine immediately after it has been working under load can result in overheating and accelerated wear of the engine components. Allow the engine to cool down before stopping. Avoiding hot engine shutdowns will maximize turbocharger shaft and bearing life.

Emergency Stopping

Emergency shutoff controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure.

Make sure that any external system components that have been operating to support engine operation are secured after any stop.Emergency Stop Buttons

Emergency Stop Button, shown mounted on a junction box.Emergency stops may be made by pushing the Emergency Stop Button located on the junction box (if equipped). Both the Button and the air inlet shutoff (if equipped) require resetting before the engine will start.

Control Panel Emergency Stop Button.If equipped with the EMCPII Control Panel, press the Emergency Stop Button for an emergency stop. The ECS must be reset before resuming operation. Move the ECS to the OFF/RESET position. The ECS can also be used to shut the engine off in an emergency. Move the ECS to the OFF/RESET position. The engine will immediately shut off.Manual Stopping

A manual shutoff shaft is provided to override the governor control. The shaft will move the fuel control linkage to the FUEL OFF position. Refer to the Model Views for the engine location of the shaft. The engine may be stopped by using the shaft and the Woodward Actuator (if equipped) or the Mechanical Governor (if equipped).

Typical Woodward Actuator Control Lever.If equipped with a Woodward Actuator, move the control lever to the FUEL OFF position.

Typical Mechanical Governor ControlIf equipped with a Mechanical Governor Control, move the control to the FUEL OFF position.Hold the lever at the FUEL OFF position until the engine stops.Air Shutoff (If Equipped)

Some engines are equipped with an air shutoff, located between the aftercooler and the turbocharger. If equipped with an air shutoff lever, move the lever to the OFF position.Manual Stop Procedure

There may be several ways to shut off your engine. Make sure the shutoff procedures are understood. Use the following general guidelines for stopping the engine.EPG Engines

If the ECS is in the AUTO position and the remote contact opens, the engine will run for a pre-programmed cool down period. This will only occur when the cool down mode is used. If the cool down mode is not used, the engine will shut off immediately.

If the ECS is in the AUTO position, the remote contact opens, and the cool down time expires, the CTR will be unlatched and the starting motors may be re-engaged.1. Open the main electrical circuit breaker to remove the load.2. The engine should be run for a cool down period before being shut off. This can be accomplished with the COOLDOWN STOP switch, or the operator can control the cool down and shut off.

To use the COOLDOWN/STOP switch, turn the ECS to the COOLDOWN/STOP position. The engine will operate for a pre-programmed time period. The timer will active the fuel shutoff after the cool down.Alternatively,

Have questions with 106871-0000?

Group cross 106871-0000 ZEXEL

106871-0000

INJECTION-PUMP ASSEMBLY