Information injection-pump assembly

BOSCH

9 400 617 993

9400617993

ZEXEL

106861-2510

1068612510

MITSUBISHI

ME098628

me098628

Rating:

Service parts 106861-2510 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME066565

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106861-2510

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 617 993

9400617993

ZEXEL

106861-2510

1068612510

MITSUBISHI

ME098628

me098628

Zexel num

Bosch num

Firm num

Name

106861-2510

9 400 617 993

ME098628 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9T K

8DC9T K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

12

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

149.5

145

154

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

16

21

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149.5

148.5

150.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1-0.6)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

134.5

132.5

136.5

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

120

100

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R1-1.5

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R1-0.9

Boost pressure

kPa

12.7

11.4

14

Boost pressure

mmHg

95

85

105

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

(13.3)

Boost pressure

kPa

34.7

34.7

34.7

Boost pressure

mmHg

260

260

260

Timer adjustment

Pump speed

r/min

980--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

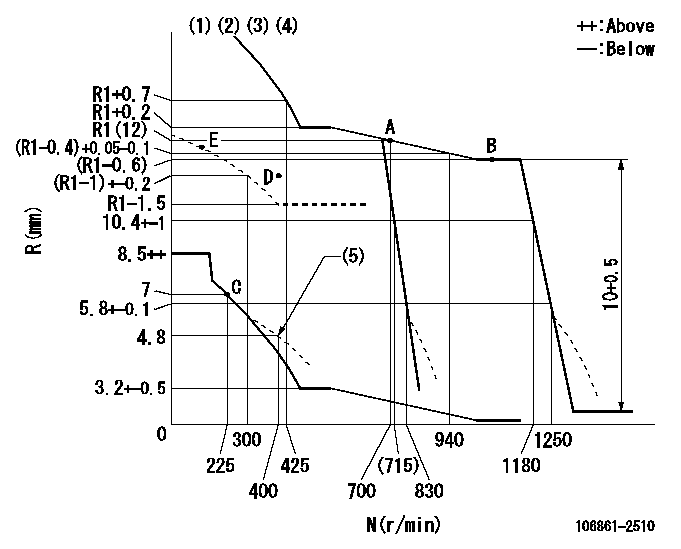

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Boost compensator cancel stroke: BSL

(5)Damper spring setting

----------

RT=1 TH=3mm BSL=1.8mm

----------

----------

RT=1 TH=3mm BSL=1.8mm

----------

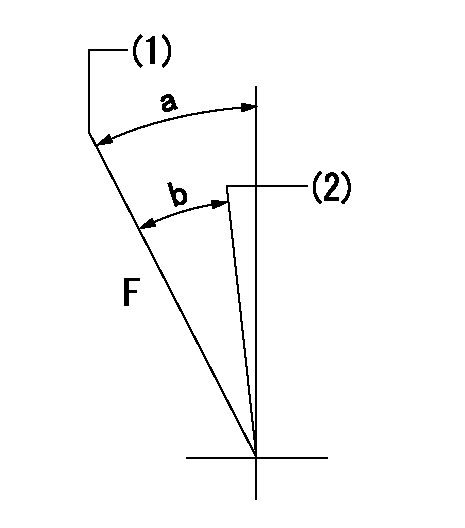

Speed control lever angle

F:Full speed

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

----------

aa=1180r/min bb=(715)r/min

----------

a=18deg+-5deg b=(10deg)+-5deg

----------

aa=1180r/min bb=(715)r/min

----------

a=18deg+-5deg b=(10deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=33.5deg+-3deg

----------

----------

a=10deg+-5deg b=33.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at shipping)

----------

aa=4.7-0.5mm bb=15.3mm

----------

a=43deg+7deg-5deg b=30deg+-5deg c=(10.5deg)

----------

aa=4.7-0.5mm bb=15.3mm

----------

a=43deg+7deg-5deg b=30deg+-5deg c=(10.5deg)

0000001501 2-STAGE CHANGEOVER DEVICE

RFD governor 2 stage changeover mechanism adjustment outline

(A) Bolt

(B) bolt

(c) Nut

(D) Return spring

(E) Bolt

(F) Bolt

(G) Screw

(H) Bolt

(I) Load lever

(J) Speed lever

(K) Air cylinder

(M Air inlet

Figure 1 is only for reference. Lever shape, etc, may vary.

1. Minimum-maximum speed specification adjustment (when running)

(a) Without applying air to the air cylinder, loosen bolts (A) and (B).

(1)High speed return L setting

(a) In the speed range Nf~Nf - 300r/min, adjust using the speed adjusting bolt to determine the temporary beginning of high speed control speed.

(b) Determine the rack position in the vicinity of Rf using the full load lever.

(c) Increase speed and confirm return distance L.

(d) Adjust using the tension lever bolt to obtain L.

(2)Setting full load rack position Rf

(a) Move the load control lever to the full side.

(b) Adjust the full load adjusting bolt so that Rf can be obtained, then fix.

(3)Setting the beginning of high speed operation Nf

(a) Adjust using bolt (E) so that Nf can be obtained, and then fix.

(4)Idle control setting (Re, Ni, Rc)

(a) Set the speed at Ns + 200r/min and move the load control lever to the idle side.

(b) Fix the lever in the position where Re can be obtained.

(c) Next, decrease speed to Ni and screw in the idle spring.

(d) Adjust to obtain rack position Ri.

(e) Increase the speed and after confirming that the rack position is Re at Ns, set the speed at 0.

(f) Confirm protrusion position Rc at idle.

(5)Damper spring adjustment

(a) Increase speed and set the speed at the rack position Rd - 0.1 mm

(b) Set using the damper spring so that the rack position Rd can be obtained.

(c) When Rd is not specified, Rd = Ri - 0.5 mm.

(6)High speed droop confirmation

(a) Return the load control lever to the full load lever position.

(b) Increase the speed and confirm that Rf can be obtained at Nf r/min.

(c) Confirm that speed is Nh at rack position Rh.

2. Variable speed specification adjustment (at operation)

(a) Remove return spring (D).

(b) Apply air pressure of 245~294 kPa {2.5~3 kg/cm2} to the air cylinder.

(c) Perform the following adjustment in this condition.

(1)Setting full load rack position Rf'

(a) Pull the load lever to the idle side.

(b) Obtain rack position Rf' using the nut (C). (Pump speed is Nf'-50 r/min.)

(2)Setting full speed Nf'

(a) Adjust using bolt (B) so that Nf can be obtained, and then fix.

(3)Low speed side setting

(a) At 350r/min, set bolt (F) at beginning of governor operation position, then fix.

3. Bolt (A) adjustment

(1)Install return spring (D) and perform the adjustments below at air pressure 0.

(a) Set at speed Nf using bolt (E).

(b) Screw in bolt (A).

(c) Screw in 1 more turn from the speed lever contact position

(d) Fix bolt (A).

(e) At this time confirm that the air cylinder's shaft moves approximately 1 mm towards the governor.

4. Lever operation confirmation using the air cylinder

(1)Apply 588 kPa {6 kg/cm2} air pressure to the air cylinder.

(2)Confirm that the cylinder piston is moved 50 mm by the spring (D).

----------

----------

----------

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Caterpillar's Scheduled Oil Sampling (S O S) analysis is the best indicator for determining what is happening inside your engine.S O S analysis is a diagnostic tool used to determine oil performance and component wear rates. S O S analysis uses a series of tests designed to identify and measure contamination such as: * soot, sulfur, etc.* degradation such as the presence of fuel, water and antifreeze in a sample of oil.* the amount of wear metals present in the oil sample.Wear metals present in the oil sample are compared to established Caterpillar norms to determine acceptability. S O S analysis must be performed on a continuing basis to be effective as an indicator. Intermittent sampling does not allow wear rate trend lines to be established. Obtain Oil Sample Every 250 Hour Interval (T & TA) or Every 500 Hour Interval (NA).Obtain S O S samples at regularly scheduled intervals to monitor the condition and maintenance requirements of your engine. Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the engine crankcase.Consult your Caterpillar dealer for complete information and assistance in establishing an S O S analysis program for your engine(s).S O S Analysis

S O S analysis is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S analysis must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Listen To Your Oil (PEDP1129) for information and benefits of S O S analysis.

S O S analysis is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S analysis must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Listen To Your Oil (PEDP1129) for information and benefits of S O S analysis.

Have questions with 106861-2510?

Group cross 106861-2510 ZEXEL

Mitsubishi

106861-2510

9 400 617 993

ME098628

INJECTION-PUMP ASSEMBLY

8DC9T

8DC9T