Information injection-pump assembly

BOSCH

9 400 617 990

9400617990

ZEXEL

106861-2470

1068612470

MITSUBISHI

ME098588

me098588

Rating:

Cross reference number

BOSCH

9 400 617 990

9400617990

ZEXEL

106861-2470

1068612470

MITSUBISHI

ME098588

me098588

Zexel num

Bosch num

Firm num

Name

106861-2470

9 400 617 990

ME098588 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9T * K 14CD INJECTION PUMP ASSY PE8P PE

8DC9T * K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

146

143

149

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

11.4

8.8

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1100++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1100.

Do not advance until starting N = 1100.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

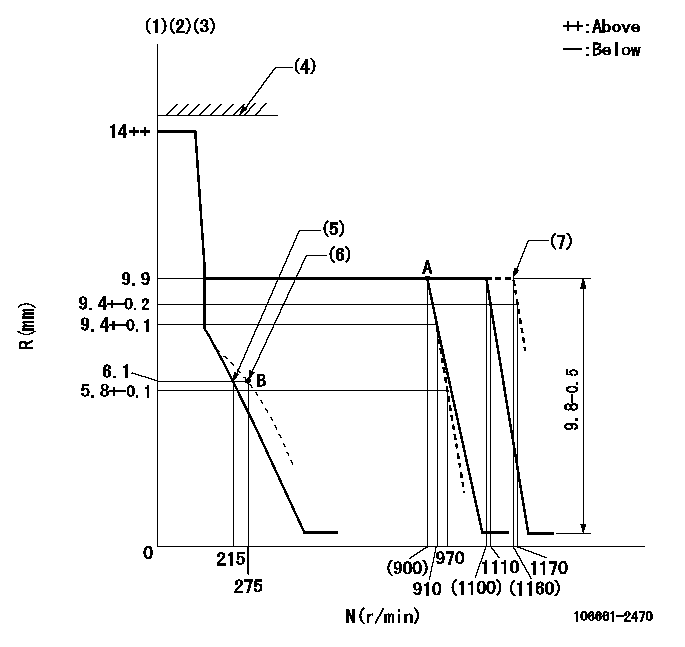

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Torque spring does not operate.

(4)RACK LIMIT not operating.

(5)Main spring setting

(6)Set idle sub-spring

(7)At delivery

----------

K=10

----------

----------

K=10

----------

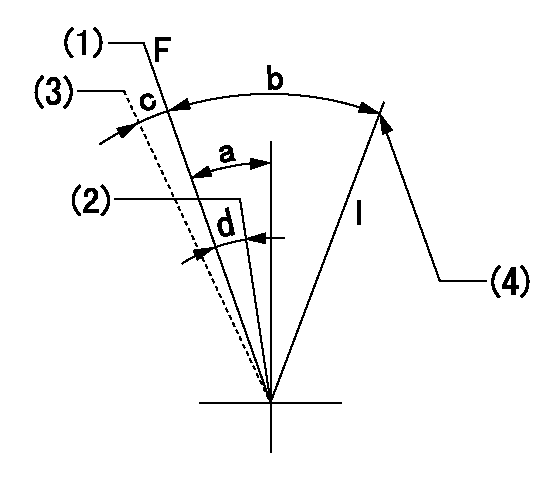

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Pump speed = bb

(3)At delivery

(4)Stopper bolt setting

----------

aa=1110r/min bb=910r/min

----------

a=7deg+-5deg b=26deg+-5deg c=(2deg) d=6deg+-5deg

----------

aa=1110r/min bb=910r/min

----------

a=7deg+-5deg b=26deg+-5deg c=(2deg) d=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=46deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Emergency Stop Push Button

Emergency Stop Push Button (ESPB)The Emergency Stop Push Button (ESPB) requires resetting both the push button and the air inlet shutoff (if equipped) before the engine will start.

Always determine the cause of the engine shutdown. Make necessary repairs before attempting restarting the engine.Emergency shutoff controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure. Refer to the Engine Stopping section of this manual for normal stopping procedures.

Oil Pressure Switch

Typical example of oil pressure switches, mounted in the rear of the junction box.An oil pressure switch has wires connected to the electrical shutoff system for alarm or shutdown functions. The oil pressure switch senses oil pressure at the bearing oil gallery. Switches may close at 48 to 62 kPa (7 to 9 psi) below actual trip point. No resetting procedure is required.Water Temperature Contactor Switch

This contactor switch is a coolant temperature sensor.The water temperature contactor switch is located near the coolant water regulator housing. Excessive water temperature closes the switch. Maximum coolant temperature to trip shutoff is 104°C (219°F). The switch opens as the coolant cools. No resetting procedure is required. The unit has wires connected to the electrical shutoff system for alarm or shutdown functions.

The sensing element must be submerged in the coolant to operate. Be sure to have an adequate water supply in the jacket water system, or engine damage could result.

Coolant Loss Sensor (If Equipped)

The optional coolant loss sensor is usually mounted near the top of the engine expansion tank or radiator. The sensor detects when the coolant level is below a preset minimum level.

This coolant loss switch, shown next to a sight glass, is mounted on the side of a radiator.If the coolant level drops below the minimum level, the sensor may sound an alarm, or cause a shutdown to avoid engine overheating or possible engine damage. Coolant must be added to the radiator or expansion tank to clear or reset the condition. In the event of intermittent engine shutdowns, the coolant water level should be checked. Add premixed coolant water to the fill tank, to within 13 mm (1/2 inch) below the filler tube.Check the expansion tank or radiator daily for proper coolant level.Overspeed Shutoffs

The electrical shutoff for the overspeed switch uses a magnetic pickup mounted in the flywheel housing. The electrical shutoff works through the fuel shutoff solenoid and air inlet shutoff (if equipped).

Magnetic pickup (1), mounted in the flywheel housing (2).Should the engine overspeed, the magnetic pickup will sense the excess speed. If overspeed is sensed, the electrical shutoff closes the air and fuel shutoff solenoids (the fuel rack will move to fuel OFF position).The overspeed shutdown has to be reset. Reset the air inlet shutoff (if equipped) and the overspeed switch. Both switches are located in the junction box or control panel.

Overspeed Shutoff Switch (Electro-Mechanical)This switch is mounted either on the tachometer drive or the governor. Excessive engine speed closes the switch by centrifugal force.If equipped with a Caterpillar Generator

Emergency Stop Push Button (ESPB)The Emergency Stop Push Button (ESPB) requires resetting both the push button and the air inlet shutoff (if equipped) before the engine will start.

Always determine the cause of the engine shutdown. Make necessary repairs before attempting restarting the engine.Emergency shutoff controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure. Refer to the Engine Stopping section of this manual for normal stopping procedures.

Oil Pressure Switch

Typical example of oil pressure switches, mounted in the rear of the junction box.An oil pressure switch has wires connected to the electrical shutoff system for alarm or shutdown functions. The oil pressure switch senses oil pressure at the bearing oil gallery. Switches may close at 48 to 62 kPa (7 to 9 psi) below actual trip point. No resetting procedure is required.Water Temperature Contactor Switch

This contactor switch is a coolant temperature sensor.The water temperature contactor switch is located near the coolant water regulator housing. Excessive water temperature closes the switch. Maximum coolant temperature to trip shutoff is 104°C (219°F). The switch opens as the coolant cools. No resetting procedure is required. The unit has wires connected to the electrical shutoff system for alarm or shutdown functions.

The sensing element must be submerged in the coolant to operate. Be sure to have an adequate water supply in the jacket water system, or engine damage could result.

Coolant Loss Sensor (If Equipped)

The optional coolant loss sensor is usually mounted near the top of the engine expansion tank or radiator. The sensor detects when the coolant level is below a preset minimum level.

This coolant loss switch, shown next to a sight glass, is mounted on the side of a radiator.If the coolant level drops below the minimum level, the sensor may sound an alarm, or cause a shutdown to avoid engine overheating or possible engine damage. Coolant must be added to the radiator or expansion tank to clear or reset the condition. In the event of intermittent engine shutdowns, the coolant water level should be checked. Add premixed coolant water to the fill tank, to within 13 mm (1/2 inch) below the filler tube.Check the expansion tank or radiator daily for proper coolant level.Overspeed Shutoffs

The electrical shutoff for the overspeed switch uses a magnetic pickup mounted in the flywheel housing. The electrical shutoff works through the fuel shutoff solenoid and air inlet shutoff (if equipped).

Magnetic pickup (1), mounted in the flywheel housing (2).Should the engine overspeed, the magnetic pickup will sense the excess speed. If overspeed is sensed, the electrical shutoff closes the air and fuel shutoff solenoids (the fuel rack will move to fuel OFF position).The overspeed shutdown has to be reset. Reset the air inlet shutoff (if equipped) and the overspeed switch. Both switches are located in the junction box or control panel.

Overspeed Shutoff Switch (Electro-Mechanical)This switch is mounted either on the tachometer drive or the governor. Excessive engine speed closes the switch by centrifugal force.If equipped with a Caterpillar Generator

Have questions with 106861-2470?

Group cross 106861-2470 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

106861-2470

9 400 617 990

ME098588

INJECTION-PUMP ASSEMBLY

8DC9T

8DC9T