Information injection-pump assembly

BOSCH

9 400 612 673

9400612673

ZEXEL

106861-2450

1068612450

MITSUBISHI

ME098571

me098571

Rating:

Service parts 106861-2450 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME066034

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106861-2450

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 673

9400612673

ZEXEL

106861-2450

1068612450

MITSUBISHI

ME098571

me098571

Zexel num

Bosch num

Firm num

Name

9 400 612 673

ME098571 MITSUBISHI

INJECTION-PUMP ASSEMBLY

8DC9TC K 14CD INJECTION PUMP ASSY PE8P PE

8DC9TC K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

131

128

134

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.1+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

11.4

8.8

14

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Timer adjustment

Pump speed

r/min

1100++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1100.

Do not advance until starting N = 1100.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

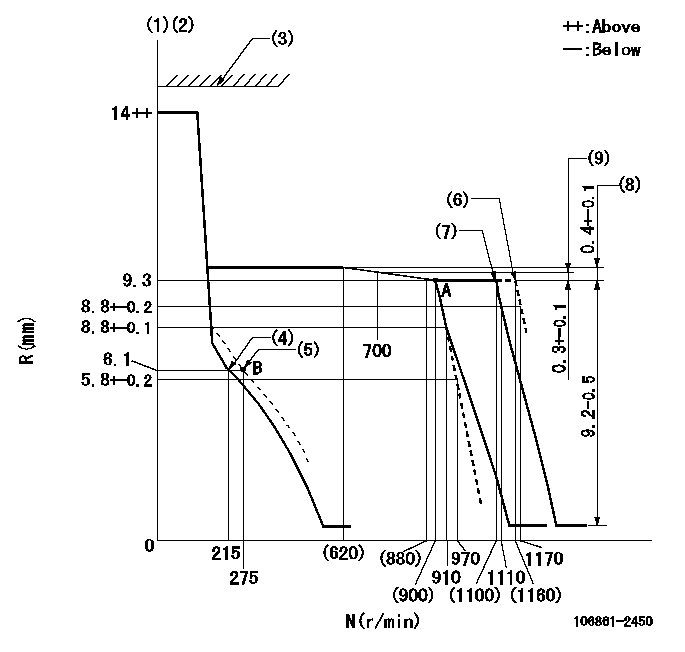

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver with rack limit not operating

(4)Main spring setting

(5)Set idle sub-spring

(6)At shipping

(7)Torque spring does not operate.

(8)Rack difference between N = N1 and N = N2

(9)Rack difference between N = N3 and N = N4

----------

K=16 N1=900r/min N2=500r/min N3=900r/min N4=700r/min

----------

----------

K=16 N1=900r/min N2=500r/min N3=900r/min N4=700r/min

----------

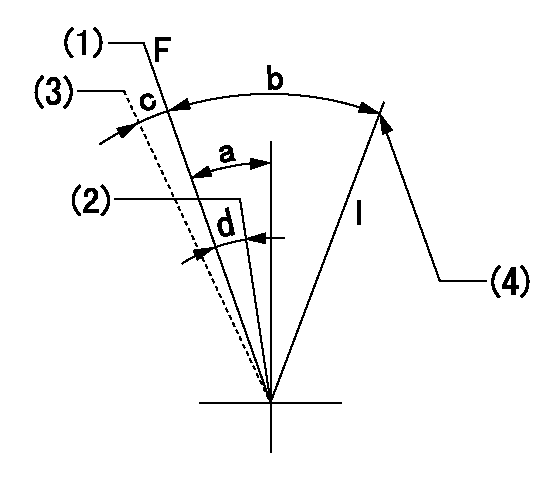

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Pump speed = bb

(3)At shipping

(4)Stopper bolt setting

----------

aa=1110r/min bb=910r/min

----------

a=10deg+-5deg b=25deg+-5deg c=(2deg) d=6deg+-5deg

----------

aa=1110r/min bb=910r/min

----------

a=10deg+-5deg b=25deg+-5deg c=(2deg) d=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=46deg+-5deg

----------

----------

a=19deg+-5deg b=46deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Total Base Number (TBN) and Fuel Sulfur Levels For Caterpillar DI Diesel Engines

The TBN required in a new oil depends on the sulfur level of the fuel used. For direct injection engines running on distillate diesel fuel, the minimum new oil TBN (by ASTM D2896) should be 10 times the fuel sulfur level, and the minimum TBN is 5 regardless of a low fuel sulfur level- refer to the following graph.

Y = oil TBN shown by ASTM D2896.

X = percent of fuel sulfur by weight.

New oil TBN (1).

Change oil when the used oil TBN limit (2) is reached.In areas where the fuel sulfur exceeds 1.5 percent, choose an oil with the highest TBN that is within the API CF-4 or CG-4 categories, and shorten the oil change interval based on oil analysis. The oil analysis should evaluate oil condition and wear metals. High TBN oils that are not within the API CF-4 or CG-4 categories can produce excessive piston deposits, leading to a loss of oil control and bore polishing.

Operating DI diesel engines with fuel sulfur levels over 1.0 percent may require shortened oil change intervals in order to maintain adequate wear protection.

Lubricant Viscosity Recommendations For Caterpillar DI Engines

The proper SAE viscosity grade oil is determined by the minimum outside temperature at cold engine start-up, and the maximum outside temperature during engine operation. Use the minimum temperature column on the chart to determine the oil viscosity required for starting a "cold soaked" engine. Use the maximum temperature column on the chart to select the viscosity for operation at the highest temperature anticipated. In general, use the highest viscosity oil available that still meets the start-up temperature requirements. Engine Lubricant Recommendations Summary

To achieve all the performance that was built into a Caterpillar engine, follow these guidelines: * Select the proper Caterpillar oil or commercial oil that meets the API specifications* Select the proper oil viscosity based on the applicable Lubricant Viscosities chart* Replace the engine oil and oil filter(s) at the intervals specified in the Operation and Maintenance Manual* Perform maintenance according to the Operation and Maintenance ManualCaterpillar Lubricating Grease

Caterpillar provides grease for a variety of applications and extreme temperature conditions. The descriptions of these products follow.Contact your Caterpillar dealer for part numbers and available container sizes. One grease may be incompatible with another grease. When using commercial grease, make sure the grease is compatible with the grease used in your system, or make sure to purge the system. Contact your supplier regarding grease compatibility questions.Multipurpose Grease

Multipurpose Lithium Complex Grease (MPG)

MPG is a NLGI No.2 general purpose lithium complex grease for light to medium duty applications. MPG has good high temperature characteristics, with a minimum dropping point of 260°C (500°F). MPG contains unleaded extreme pressure additives and antiwear and corrosion inhibitors to provide extra protection in a variety of construction, agricultural and automotive applications.MPG meets the requirements for extended service intervals of automotive chassis points and wheel bearings with disc brakes, particularly in passenger cars, vans, light trucks and

The TBN required in a new oil depends on the sulfur level of the fuel used. For direct injection engines running on distillate diesel fuel, the minimum new oil TBN (by ASTM D2896) should be 10 times the fuel sulfur level, and the minimum TBN is 5 regardless of a low fuel sulfur level- refer to the following graph.

Y = oil TBN shown by ASTM D2896.

X = percent of fuel sulfur by weight.

New oil TBN (1).

Change oil when the used oil TBN limit (2) is reached.In areas where the fuel sulfur exceeds 1.5 percent, choose an oil with the highest TBN that is within the API CF-4 or CG-4 categories, and shorten the oil change interval based on oil analysis. The oil analysis should evaluate oil condition and wear metals. High TBN oils that are not within the API CF-4 or CG-4 categories can produce excessive piston deposits, leading to a loss of oil control and bore polishing.

Operating DI diesel engines with fuel sulfur levels over 1.0 percent may require shortened oil change intervals in order to maintain adequate wear protection.

Lubricant Viscosity Recommendations For Caterpillar DI Engines

The proper SAE viscosity grade oil is determined by the minimum outside temperature at cold engine start-up, and the maximum outside temperature during engine operation. Use the minimum temperature column on the chart to determine the oil viscosity required for starting a "cold soaked" engine. Use the maximum temperature column on the chart to select the viscosity for operation at the highest temperature anticipated. In general, use the highest viscosity oil available that still meets the start-up temperature requirements. Engine Lubricant Recommendations Summary

To achieve all the performance that was built into a Caterpillar engine, follow these guidelines: * Select the proper Caterpillar oil or commercial oil that meets the API specifications* Select the proper oil viscosity based on the applicable Lubricant Viscosities chart* Replace the engine oil and oil filter(s) at the intervals specified in the Operation and Maintenance Manual* Perform maintenance according to the Operation and Maintenance ManualCaterpillar Lubricating Grease

Caterpillar provides grease for a variety of applications and extreme temperature conditions. The descriptions of these products follow.Contact your Caterpillar dealer for part numbers and available container sizes. One grease may be incompatible with another grease. When using commercial grease, make sure the grease is compatible with the grease used in your system, or make sure to purge the system. Contact your supplier regarding grease compatibility questions.Multipurpose Grease

Multipurpose Lithium Complex Grease (MPG)

MPG is a NLGI No.2 general purpose lithium complex grease for light to medium duty applications. MPG has good high temperature characteristics, with a minimum dropping point of 260°C (500°F). MPG contains unleaded extreme pressure additives and antiwear and corrosion inhibitors to provide extra protection in a variety of construction, agricultural and automotive applications.MPG meets the requirements for extended service intervals of automotive chassis points and wheel bearings with disc brakes, particularly in passenger cars, vans, light trucks and