Information injection-pump assembly

ZEXEL

106861-2270

1068612270

Rating:

Service parts 106861-2270 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME066565

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106861-2270

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106861-2270

1068612270

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

137

132.9

141.1

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

18.5

16

21

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

137

136

138

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

D

Rack position

11.3

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

130

126.3

133.7

Fixing the lever

*

Boost pressure

kPa

12.7

12.7

12.7

Boost pressure

mmHg

95

95

95

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

120

100

140

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

9.9

Boost pressure

kPa

2

2

2

Boost pressure

mmHg

15

15

15

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

11.3

Boost pressure

kPa

12.7

11.4

14

Boost pressure

mmHg

95

85

105

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

(12.5)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

980--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

(900)

Advance angle

deg.

0

0

0

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

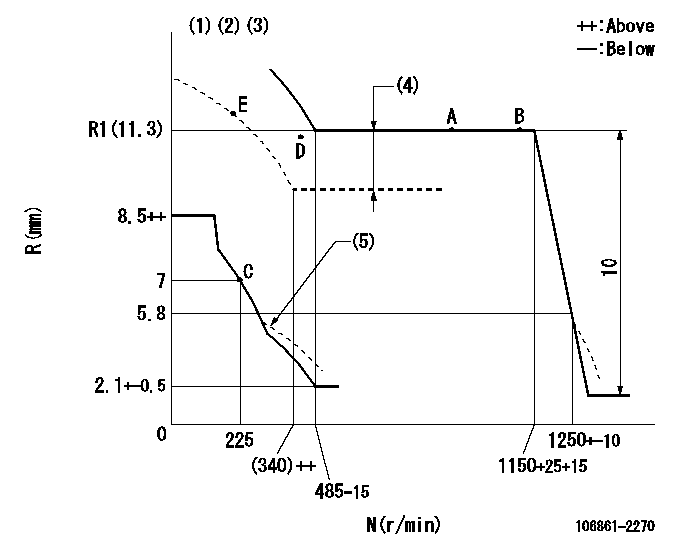

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Boost compensator cancel stroke: BSL

(4)Boost compensator stroke: BCL

(5)Damper spring setting: DL

----------

RT=1 TH=2.7mm BSL=1.6mm BCL=1.4+-0.1mm DL=5.8-0.2mm

----------

----------

RT=1 TH=2.7mm BSL=1.6mm BCL=1.4+-0.1mm DL=5.8-0.2mm

----------

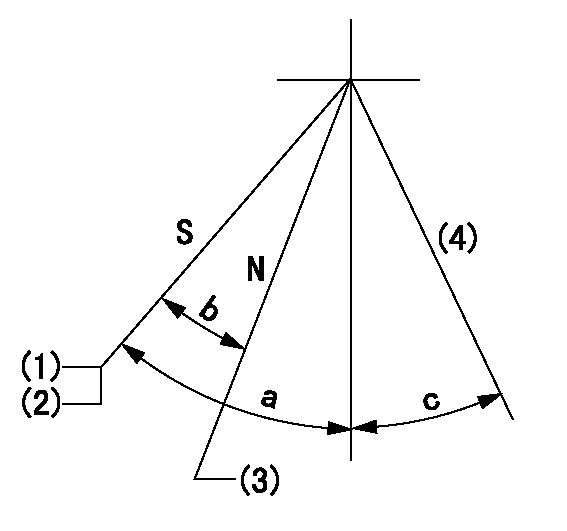

Speed control lever angle

F:Full speed

----------

----------

a=18deg+-5deg

----------

----------

a=18deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=32.5deg+-3deg

----------

----------

a=10deg+-5deg b=32.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at shipping)

----------

aa=4.7-0.5mm bb=15.3mm

----------

a=43deg+7deg-5deg b=30deg+-5deg c=(10.5deg)

----------

aa=4.7-0.5mm bb=15.3mm

----------

a=43deg+7deg-5deg b=30deg+-5deg c=(10.5deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=6.7mm

----------

----------

N1=325+-5r/min Ra=6.7mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(40deg)

----------

----------

a=(40deg)

Information:

Lubrication Specifications

Crankcase Lubricating Oils

Use oils which meet Engine Service Classification CD (MIL-L-2104D) or CD/TO-2. These are additive-type oils that have been approved for use in Caterpillar Diesel Engines.Consult the "EMA Lubricating Oils Data Book," Form SEBU5939, for a listing of CD oil brands.The proper SAE grade of oil to select is determined by the ambient temperature at which the engine is started and the maximum ambient temperature in which the engine will be operating. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricating Grease

Use Multipurpose-type Grease (MPGM) which contains 3-5% molybdenum disulfide conforming to MIL-M-7866, and a suitable corrosion inhibitor. NLGI No. 2 Grade is suitable for most temperatures. Use NLGI No. 0 or No. 1 Grade for extremely low temperatures.Recommended Lubricant Viscosities

Air Starting Motor Oiler: Use SAE 10W in all temperatures.Flywheel Clutch Bearing Reservoir: Use SAE 30 in all temperatures. Fuel Specifications

No. 2 fuel oil and No. 2D diesel fuel are recommended for use in Caterpillar Diesel Engines. In extreme cold temperatures use No. 1 fuel oil or No. 1D diesel fuel.In selecting a fuel, note that distillate fuels are especially desirable because the fuel is heated to a vaporous state and condensed, thus eliminating all sediment and residue.There is considerable variation in the composition of fuels distributed under the No. 2 grade classifications. For desirable engine service it is most important to give special attention to cetane no., water and sediment, pour point, cloud point and sulphur content. USE THE LOWEST PRICE DISTILLATE FUEL WHICH MEETS THE FOLLOWING REQUIREMENTS.Water and Sediment 0.1% sedimentCetane No. (PC Engine) 35 minimum(DI Engine) 40 minimumPour Point 10°F (6°C) below ambient temperatureCloud Point No higher than ambient temperatureSulphur Content* Adjust oil change periodGravity 32-40 A.P.I. at 60°F (15.6°C)*See the topic SULPHUR CONTENT. Cetane No: This is an indication of a fuel's ignition quality and should not be less than 35 for the PC engine and 40 for the DI engine. For high altitude operation or cold weather starting, a higher cetane number is required. Water and Sediment: A good clean fuel will contain no more than 0.1% sediment and water. Dirty fuels lead to early filter plugging and in addition can result in the formation of gums and resins reducing filter and engine life. Pour Point: The pour point of the fuel has no effect on engine performance, as long as the fuel is fluid enough to flow from the fuel tank to the engine. The pour point of the fuel should be at least 10°F (6°C) below the lowest atmospheric temperature at which the engine must start and operate. In extremely cold temperatures it may be necessary to use No. 1 fuel oil or No. 1D diesel fuel. Cloud Point: Cloud point is the temperature at which wax crystals become visible and is generally above the pour point of

Crankcase Lubricating Oils

Use oils which meet Engine Service Classification CD (MIL-L-2104D) or CD/TO-2. These are additive-type oils that have been approved for use in Caterpillar Diesel Engines.Consult the "EMA Lubricating Oils Data Book," Form SEBU5939, for a listing of CD oil brands.The proper SAE grade of oil to select is determined by the ambient temperature at which the engine is started and the maximum ambient temperature in which the engine will be operating. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting. If the oil will flow off, the oil is fluid enough to circulate properly.Lubricating Grease

Use Multipurpose-type Grease (MPGM) which contains 3-5% molybdenum disulfide conforming to MIL-M-7866, and a suitable corrosion inhibitor. NLGI No. 2 Grade is suitable for most temperatures. Use NLGI No. 0 or No. 1 Grade for extremely low temperatures.Recommended Lubricant Viscosities

Air Starting Motor Oiler: Use SAE 10W in all temperatures.Flywheel Clutch Bearing Reservoir: Use SAE 30 in all temperatures. Fuel Specifications

No. 2 fuel oil and No. 2D diesel fuel are recommended for use in Caterpillar Diesel Engines. In extreme cold temperatures use No. 1 fuel oil or No. 1D diesel fuel.In selecting a fuel, note that distillate fuels are especially desirable because the fuel is heated to a vaporous state and condensed, thus eliminating all sediment and residue.There is considerable variation in the composition of fuels distributed under the No. 2 grade classifications. For desirable engine service it is most important to give special attention to cetane no., water and sediment, pour point, cloud point and sulphur content. USE THE LOWEST PRICE DISTILLATE FUEL WHICH MEETS THE FOLLOWING REQUIREMENTS.Water and Sediment 0.1% sedimentCetane No. (PC Engine) 35 minimum(DI Engine) 40 minimumPour Point 10°F (6°C) below ambient temperatureCloud Point No higher than ambient temperatureSulphur Content* Adjust oil change periodGravity 32-40 A.P.I. at 60°F (15.6°C)*See the topic SULPHUR CONTENT. Cetane No: This is an indication of a fuel's ignition quality and should not be less than 35 for the PC engine and 40 for the DI engine. For high altitude operation or cold weather starting, a higher cetane number is required. Water and Sediment: A good clean fuel will contain no more than 0.1% sediment and water. Dirty fuels lead to early filter plugging and in addition can result in the formation of gums and resins reducing filter and engine life. Pour Point: The pour point of the fuel has no effect on engine performance, as long as the fuel is fluid enough to flow from the fuel tank to the engine. The pour point of the fuel should be at least 10°F (6°C) below the lowest atmospheric temperature at which the engine must start and operate. In extremely cold temperatures it may be necessary to use No. 1 fuel oil or No. 1D diesel fuel. Cloud Point: Cloud point is the temperature at which wax crystals become visible and is generally above the pour point of