Information injection-pump assembly

ZEXEL

106861-2000

1068612000

Rating:

Service parts 106861-2000 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME066034

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106861-2000

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106861-2000

1068612000

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.5 45.5

Cyl.1-2 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-3 deg. 135 134.5 135.5

Cal 1-3 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-5 deg. 225 224.5 225.5

Cal 1-5 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cal 1-8 deg. 315 314.5 315.5

Cal 1-8 deg. 315 314.5 315.5

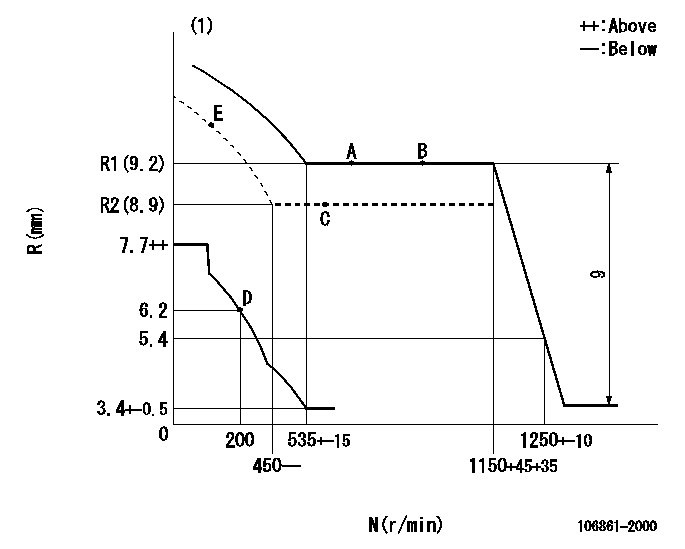

Injection quantity adjustment

Adjusting point

-

Rack position

9.2

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

134

130

138

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

6.2+-0.5

Pump speed

r/min

200

200

200

Each cylinder's injection qty

mm3/st.

18.5

15.7

21.3

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.2)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

134

133

135

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.2)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

141

135.4

146.6

Difference in delivery

mm3/st.

11.2

11.2

11.2

Fixing the lever

*

Boost pressure

kPa

40

40

Boost pressure

mmHg

300

300

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(8.9)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

120

116

124

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

E

Rack position

9.9+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

110

90

130

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(8.9)

Boost pressure

kPa

22

20.7

23.3

Boost pressure

mmHg

165

155

175

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(9.2)

Boost pressure

kPa

30

23.3

36.7

Boost pressure

mmHg

235

185

285

Timer adjustment

Pump speed

r/min

850+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.9

0.4

1.4

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

23

22.5

23.5

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

----------

DL=5.4-0.2mm

----------

----------

DL=5.4-0.2mm

----------

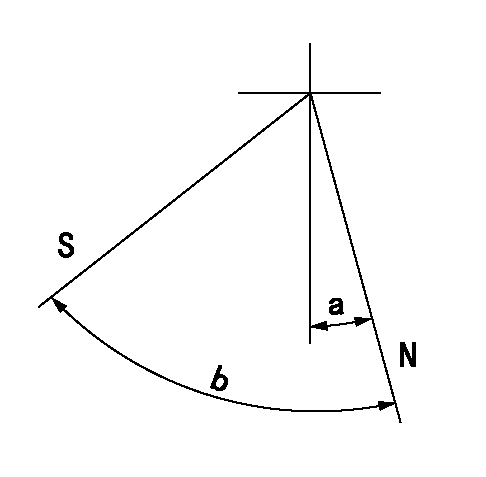

Speed control lever angle

F:Full speed

----------

----------

a=18deg+-5deg

----------

----------

a=18deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=21.5deg+-3deg

----------

----------

a=10deg+-5deg b=21.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=10deg+-5deg b=64deg+-5deg

----------

----------

a=10deg+-5deg b=64deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.9mm

----------

----------

N1=325+-5r/min Ra=5.9mm

----------

Information:

04Feb2016

U-58

A-46

D-55

O-52

Parts stock action only

PRODUCT IMPROVEMENT PROGRAM FOR REMOVING 398-1498 AND 463-1678 FUEL INJECTION PUMPS FROM DEALER PARTS STOCK

7750 PI70604

Caterpillar’s obligations under this Service Letter are subject to, and shall not apply in contravention of, the laws, rules, regulations, directives, ordinances, orders, or statutes of the United States, or of any other applicable jurisdiction, without recourse or liability with respect to Caterpillar.

When submitting claim for Parts Stock Action, Use the appropriate 99Z as the s/n, the appropriate Service Letter Program Number as the Part number in the Part Causing Failure field, "7751" as the Group Number, "56" as the Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

31May2016

PROBLEM

The existing 398-1498 and 463-1678 Fuel Injection Pumps can fail. Fuel Injection Pumps up to and inclusive of component serial number 06369GJG, are suspect.

ACTION REQUIRED

Inspect all 398-1498 and 463-1678 Fuel Injection Pumps in dealer parts stock. Review the component serial number on each 398-1498 and 463-1678 Fuel Injection Pump. The Fuel Injection Pump component serial number can be located on the Fuel Injection Pump data plate, affixed to the side of the Fuel Injection Pump body.

The Fuel Injection Pump component serial number is alphanumeric, Refer to Image 1 for explanation on component serial number translation. In the given example the date code would translate to the following - 6369th pump built in July 2015.

NOTE - The build facility is not applicable in determining if the Fuel Injection Pump is suspect or not.

Refer to Image 2 for the build month and build year translation table.

Please action according to the following build month and build year color code -

Red = Remove from dealer part stock

Orange = Check Fuel Injection Pump Serial Number (06369 and below = Remove from dealer part stock / 06370 and Up = Return to dealer part stock).

Green = OK, Return to dealer part stock.

- If the Fuel Injection Pump is removed from dealer parts stock. Refer to the Service Claim Allowances and Parts Disposition.

- If the Fuel Injection Pump is returned to dealer parts stock, mark the box as inspected.

Image1

Image2

SERVICE CLAIM ALLOWANCES

Submit one claim for all Fuel Injection Pumps removed from dealer parts stock. Include the date code (e.g. 06369GJG) in the claim story for each Fuel Injection Pump removed from dealer parts stock.

PARTS DISPOSITION

NACD:

Hold all 398-1498 and 463-1678 Fuel Injection Pumps removed from dealer parts stock for a Parts Return Request (PRR). A Parts Return Request (PRR) will be issued to you through the Send-It-Back process after the claim is submitted. Make sure to list the service letter program number on the packing