Information injection-pump assembly

ZEXEL

106861-1326

1068611326

ISUZU

1156017807

1156017807

Rating:

Service parts 106861-1326 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/22.1(225)

15.

NOZZLE SET

Include in #1:

106861-1326

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106861-1326

1068611326

ISUZU

1156017807

1156017807

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-3-

6-5-4-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-3 deg. 135 134.75 135.25

Cal 1-3 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

B

Rack position

8.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

85.6

84.1

87.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

95.9

91.9

99.9

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

5.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

137

137

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Injection quantity adjustment_05

Adjusting point

G

Rack position

8.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

94.8

90.8

98.8

Max. variation between cylinders

%

3

3

3

Fixing the lever

*

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

(1075)

Advance angle

deg.

1

0.5

1

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.5

3.5

Timer adjustment_05

Pump speed

r/min

1250

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

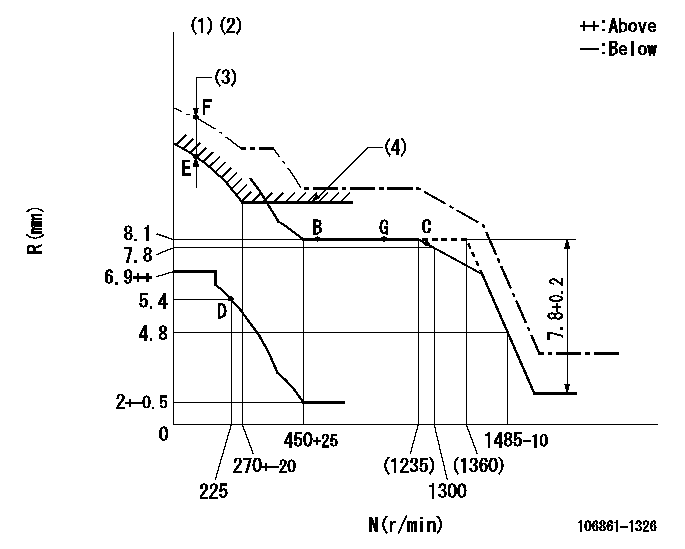

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(3)At excess fuel lever operation: not exceeding EXL

(4)Excess fuel setting for starting: SXL

----------

EXL=2mm SXL=9.2+-0.1mm

----------

----------

EXL=2mm SXL=9.2+-0.1mm

----------

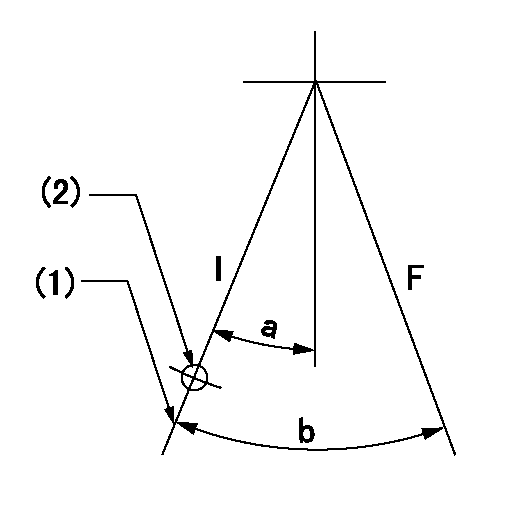

Speed control lever angle

F:Full speed

----------

----------

a=9deg+-5deg

----------

----------

a=9deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

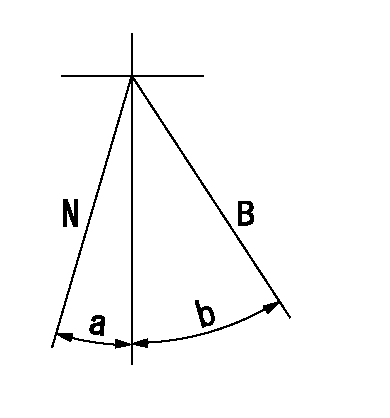

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(170deg)

----------

aa=12deg

----------

a=(170deg)

Information:

6. Coat the seal of the element with a thin film of clean engine oil or antifreeze. 7. Install the element. Tighten it until the seal contacts the base, then tighten it an additional 3/4 turn. 8. Open the inlet valve and the outlet valve. 9. Maintain the coolant level above the low level plate. 10. Clean and install the radiator cap.11. Start the engine and check for leaks.Brakes

Inspect - Adjust

The machine must be level, the bowl lowered, and the parking brake applied.1. Block the wheels securely.2. Start the engine. 3. When the air pressure reaches the NORMAL range, stop the engine. 4. Release the parking/emergency brake. 5. Measure the distance from the rotochamber to the slack adjuster clevis retaining pin. 6. Apply the service brake and measure the amount of travel of the rod. If the travel is 76 mm (3 inches) or more, adjust the brake.7. Measure the brake rotochamber rod travel of all four wheel brakes. Scraper rotochambers are located inside the push frame.To Adjust

1. Loosen the adjustment locking bolt. 2. Turn the adjusting bolt, as required, until the travel is 41 mm (1.62 inches). 3. Tighten the locking bolt. 4. Apply and release the brakes, watching the rotochamber rod for binding.5. Observe the diaphragm for leaks. 6. Start the engine and allow air pressure to reach 690 kPa (100 psi) or in the green range on the air pressure gauge.7. Apply the parking brake.8. Stop the engine.9. Remove the blocking from the wheels.Check the Air System for Leaks

1. Start the engine and allow air pressure to reach 690 kPa (100 psi) or in the green range on the air pressure gauge. 2. Apply the service brakes and hold them in the applied condition.3. Stop the engine.4. With the brakes applied, watch the air pressure gauge.5. The pressure should drop no more than 35 kPa (5 psi) in 10 minutes.6. If the air pressure loss is greater than 35 kPa (5 psi), inspect the air lines and connections. Make any necessary repairs.To Test Brakes

Be sure the area around the vehicle is clear of personnel and obstructions.Fasten the seat belt before operating the vehicle.Test the brakes on a dry, level surface.

The vehicle must be on a dry, level surface, the bowl lowered and the parking brake applied.The following tests are to determine if the service brake or parking/emergency brake is functional. These tests are not intended to measure maximum brake holding effort.Brake holding effort required to hold a vehicle at a specific engine rpm will vary from vehicle to vehicle due to differences in engine setting, power train efficiency, etc., as well as differences in brake holding ability.Engine rpm at beginning of vehicle movement, with service or parking/emergency brake applied, should be compared against the engine rpm your specific vehicle was able to hold on a prior test, as an indication of system deterioration.Service Brake

1. Start the engine. Allow the engine to reach the normal operating temperature.2. When air pressure registers 690 kPa (100 psi) or

Inspect - Adjust

The machine must be level, the bowl lowered, and the parking brake applied.1. Block the wheels securely.2. Start the engine. 3. When the air pressure reaches the NORMAL range, stop the engine. 4. Release the parking/emergency brake. 5. Measure the distance from the rotochamber to the slack adjuster clevis retaining pin. 6. Apply the service brake and measure the amount of travel of the rod. If the travel is 76 mm (3 inches) or more, adjust the brake.7. Measure the brake rotochamber rod travel of all four wheel brakes. Scraper rotochambers are located inside the push frame.To Adjust

1. Loosen the adjustment locking bolt. 2. Turn the adjusting bolt, as required, until the travel is 41 mm (1.62 inches). 3. Tighten the locking bolt. 4. Apply and release the brakes, watching the rotochamber rod for binding.5. Observe the diaphragm for leaks. 6. Start the engine and allow air pressure to reach 690 kPa (100 psi) or in the green range on the air pressure gauge.7. Apply the parking brake.8. Stop the engine.9. Remove the blocking from the wheels.Check the Air System for Leaks

1. Start the engine and allow air pressure to reach 690 kPa (100 psi) or in the green range on the air pressure gauge. 2. Apply the service brakes and hold them in the applied condition.3. Stop the engine.4. With the brakes applied, watch the air pressure gauge.5. The pressure should drop no more than 35 kPa (5 psi) in 10 minutes.6. If the air pressure loss is greater than 35 kPa (5 psi), inspect the air lines and connections. Make any necessary repairs.To Test Brakes

Be sure the area around the vehicle is clear of personnel and obstructions.Fasten the seat belt before operating the vehicle.Test the brakes on a dry, level surface.

The vehicle must be on a dry, level surface, the bowl lowered and the parking brake applied.The following tests are to determine if the service brake or parking/emergency brake is functional. These tests are not intended to measure maximum brake holding effort.Brake holding effort required to hold a vehicle at a specific engine rpm will vary from vehicle to vehicle due to differences in engine setting, power train efficiency, etc., as well as differences in brake holding ability.Engine rpm at beginning of vehicle movement, with service or parking/emergency brake applied, should be compared against the engine rpm your specific vehicle was able to hold on a prior test, as an indication of system deterioration.Service Brake

1. Start the engine. Allow the engine to reach the normal operating temperature.2. When air pressure registers 690 kPa (100 psi) or