Information injection-pump assembly

BOSCH

9 400 617 948

9400617948

ZEXEL

106861-0687

1068610687

NISSAN-DIESEL

1670097565

1670097565

Rating:

Cross reference number

BOSCH

9 400 617 948

9400617948

ZEXEL

106861-0687

1068610687

NISSAN-DIESEL

1670097565

1670097565

Zexel num

Bosch num

Firm num

Name

106861-0687

9 400 617 948

1670097565 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RD8T * K

RD8T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.3

3.25

3.35

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.1

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

134

131

137

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

136

134

138

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.4

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

93.8

91.8

95.8

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.6+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

17

15

19

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.4

Boost pressure

kPa

9.3

6.6

12

Boost pressure

mmHg

70

50

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10.9

Boost pressure

kPa

14.7

12

17.4

Boost pressure

mmHg

110

90

130

Boost compensator adjustment_03

Pump speed

r/min

500

500

500

Rack position

11.1

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

850

Advance angle

deg.

1

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.1

0.6

1.6

Timer adjustment_04

Pump speed

r/min

1200

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

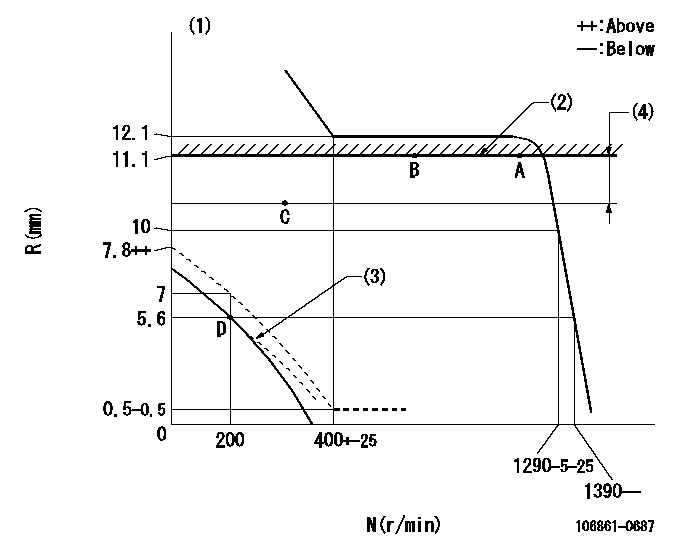

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)After completing adjustment of the broken line, set the lever at the unbroken line position.

(2)Rack limit using the stop lever: R1

(3)Beginning of damper spring operation: DL

(4)Boost compensator stroke: BCL

----------

R1=11.1mm DL=5.1-0.2mm BCL=0.7mm

----------

----------

R1=11.1mm DL=5.1-0.2mm BCL=0.7mm

----------

0000000901

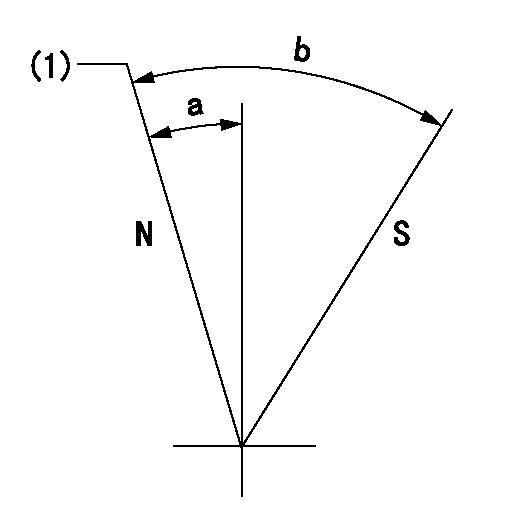

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=25deg+-3deg

----------

----------

a=16deg+-5deg b=25deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

----------

aa=11mm

----------

a=13deg+-5deg b=33.5deg+-5deg

----------

aa=11mm

----------

a=13deg+-5deg b=33.5deg+-5deg

Information:

PROBLEM

The front suspension A-Frame bearing may not be receiving an adequate amount of grease on machines that are equipped with the factory fitted Automatic Lubrication System. An inadequate amount of grease supply to the bearing does not promote purging of grease through the joint, especially in severe applications. This may result in premature wear of the bearing.

A larger sized injector is available which increases the amount of grease that is supplied to the bearing

Note: This service letter covers machines with factory fitted Automatic Lubrication Systems only. Dealer installed Automatic Lubrications Systems are not covered.

AFFECTED PRODUCT

Model Identification Number

735B L4D00368, 372, 375-380, 384-403

T4P00253-00258, 268-271, 275-277, 280-282, 284-286, 290-292, 302, 304

740B L4E00374-00378, 380, 385, 390, 392-393, 401-403, 407-408, 411, 419, 429-430, 433-437, 440, 443-449, 451, 453-455, 459, 465, 469, 471, 478, 480, 489, 492, 505, 511, 517, 522-529, 533, 535, 543, 549-550, 558, 560, 563, 567, 570, 575-576, 584, 592, 609-610, 612-616, 622, 624-627, 633-634, 643, 666, 670-673, 679-682, 687-694, 701-702, 708, 710, 712, 715-716, 722, 726-728, 734-735, 738, 741-743, 745-746, 755-757, 760, 763, 768, 774, 777, 779, 784-785, 788-789, 792, 796-799, 802-803, 805, 810, 812-813, 816-817, 821-822, 826-828, 833, 837, 842, 851, 853, 857, 861, 865-867, 881-882, 885, 887, 890-891, 896, 900, 903-904, 909-910, 912-915, 917-919, 921, 924-925, 927, 932-933, 945-950, 955-957, 962-971, 976-980, 985

T4R00267-00273, 278, 282-283, 289, 294, 299-300, 309-310, 322-323, 327, 339, 342, 348, 352, 354, 356, 359-360, 362-369, 371, 376-377, 393, 406, 423, 427, 431-432, 450, 518, 539-540, 543-546, 550, 557, 568, 581-582, 587-590

740B EJ L4F00383-00388

T4S00272-00274, 276-279, 282, 289-290, 296-299, 301, 304-309, 311

PARTS NEEDED

Qty

Part Number Description

1 1926212 INJECTOR

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 16% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

See attached rework procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-8000 hrs,

0-48 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 0.5-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

(1). Remove the grease injector from the manifold that is located on the right side of the front chassis. See Image 1.1.1 for location.

(2). Install new 192-6212 Injector.

(3). Purge new injector by pressing the Test Switch on the Auto Lube pump. See Image 1.1.2 for test switch location.

(4). Install the grease line to the injector.

Image1.1.1

Image1.1.2

Have questions with 106861-0687?

Group cross 106861-0687 ZEXEL

Nissan-Diesel

Nissan-Diesel

106861-0687

9 400 617 948

1670097565

INJECTION-PUMP ASSEMBLY

RD8T

RD8T