Information injection-pump assembly

ZEXEL

106861-0160

1068610160

Rating:

Service parts 106861-0160 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97012

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106861-0160

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106861-0160

1068610160

Zexel num

Bosch num

Firm num

Name

106861-0160

INJECTION-PUMP ASSEMBLY

14CD PE8P PE

14CD PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-5-

4-3-6-2

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.5 45.5

Cal 1-8 deg. 45 44.5 45.5

Difference between angles 2

Cal 1-7 deg. 90 89.5 90.5

Cal 1-7 deg. 90 89.5 90.5

Difference between angles 3

Cal 1-5 deg. 135 134.5 135.5

Cal 1-5 deg. 135 134.5 135.5

Difference between angles 4

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 5

Cal 1-3 deg. 225 224.5 225.5

Cal 1-3 deg. 225 224.5 225.5

Difference between angles 6

Cal 1-6 deg. 270 269.5 270.5

Cal 1-6 deg. 270 269.5 270.5

Difference between angles 7

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.8

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

113.8

112.8

114.8

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

116

113

119

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

9.8

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

120.6

116.6

124.6

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.9+-0.5

Pump speed

r/min

205

205

205

Average injection quantity

mm3/st.

18.5

16.6

20.4

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

10.4+-0.

5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

104

102

106

Fixing the lever

*

Timer adjustment

Pump speed

r/min

300+100

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

3

2.5

3.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

5.6

5.1

6.1

Timer adjustment_04

Pump speed

r/min

1250+50

Advance angle

deg.

8

7.5

8.5

Remarks

Finish

Finish

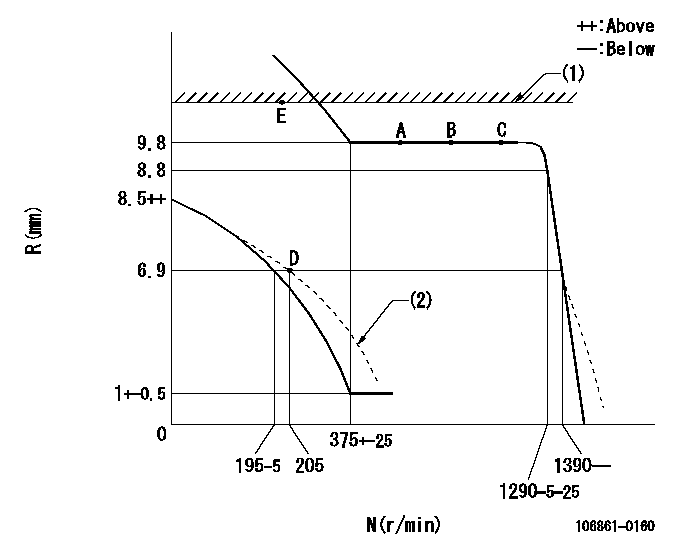

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT: RAL

(2)Adjust the damper spring so that pump speed is N1 and rack position is R1.

----------

RAL=(10.4+0.2)mm N1=200r/min R1=6.9mm

----------

----------

RAL=(10.4+0.2)mm N1=200r/min R1=6.9mm

----------

0000000901

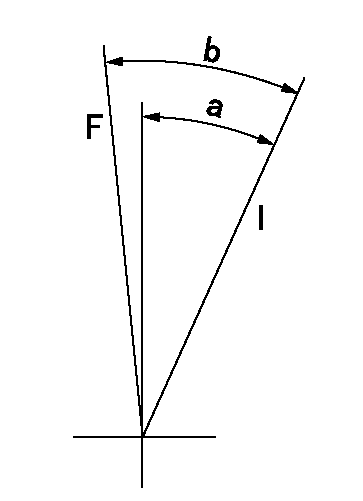

F:Full load

I:Idle

----------

----------

a=(15deg) b=17deg+-2deg

----------

----------

a=(15deg) b=17deg+-2deg

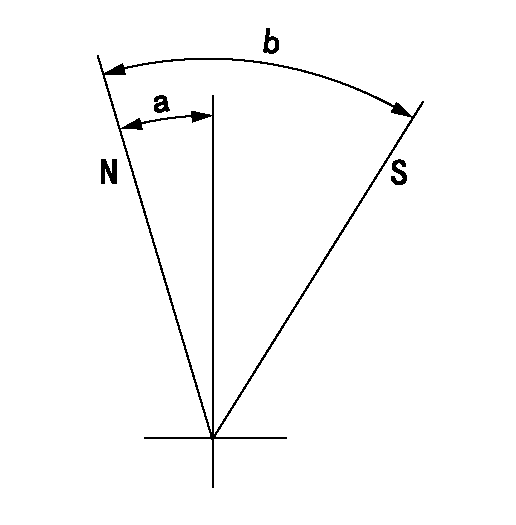

Stop lever angle

N:Normal

S:Stop the pump.

----------

----------

a=8.3deg b=(30.5deg)

----------

----------

a=8.3deg b=(30.5deg)

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=300r/min Ra=5.5mm

----------

----------

N1=300r/min Ra=5.5mm

----------

Information:

Core Management

Please refer to the Caterpillar® Core Management Information System (CMIS 2) Parts Information application describing all reman part/CAF and related information. Also refer to other CMIS 2 inquiry applications such as Customer Profiles, Inspection Reason Codes, Inspection Line Inquiry, Add Charge Information, Entitlement Activity, Entitlement Inquiry, CCR Inquiry, CCR Entry, Shipment Processing; Process Packaging Grief; and Reporting to properly manage core returns and monitor inspection performance. This information will be available to all dealers worldwide after your CMIS 2 conversion date. In the meantime, please continue to use the current CMIS Entitlement Parts Inquiry Screen describing the list of parts in a Core Acceptability Family (CAF) and related part number detail.

For the latest updates of Reman Policies and Core Management (SELD0122), Core Management Systems & Operations Procedures (SELD0040), and Shipping Instructions (SELD0039), go to the Reman Dealer website https://reman.cat.com

If you have any questions regarding core return processing, feel free to call Corinth toll free at (800) 537-2928. For assistance with technical questions, call the Peoria Reman Customer Satisfaction Hot Line also toll free at (888) 88-REMAN or use our E-mail address--Reman_Help.

RWSmith

Remanufactured Products Group

LC-2148 (309) 675-5445

Have questions with 106861-0160?

Group cross 106861-0160 ZEXEL

Nissan-Diesel

106861-0160

INJECTION-PUMP ASSEMBLY